phyphar vertical mill raw

Vertical raw mill pradeep kumar PPT Free Download

2013年5月15日 The vertical raw mill uses compression, shear and impact forces for grinding raw materials into powder. Materials are fed into the center of a grinding plate and distributed under rolling pressure from grinding rollers.

More

Review on vertical roller mill in cement industry its performance ...

2021年1月1日 For the past three decades the vertical roller mill has emerged to be the preferred choice for grinding raw materials. With the grinding capacity of a vertical roller mill

More

Modeling of vertical mill raw meal grinding process and optimal

The stability of vertical mill raw meal grinding process affect the yield and quality of cement clinker. Due to the nonlinear of grinding process, random variation of working conditions, and

More

Cement Application Page - Vertical Raw Mill - Promecon

The Vertical Raw Mill (VRM) is a pivotal component in the grinding process within a cement plant. Efficient control and optimization of this process are critical for the quality of the end

More

PROCESS OPTIMISATION FOR LOESCHE GRINDING PLANTS

a vertical roller mill (VRM) • Surpasses the classic methods if the controlled process demonstrates significant disturbances • A high degree of attention to the process states is required in order

More

Raw mills for all requirements Gebr. Pfeiffer

Grinding of cement raw material – material separation in cyclones. The cement raw material mixtures are ground, dried, and classified in the Pfeiffer vertical roller mill. For drying the material, hot gases are directed into the mill.

More

(PDF) LEARNING FROM OTHER INDUSTRIES; WHY THE

2019年4月16日 Vertical roller mills (VRM) have been used extensively for comminuting both cement raw materials and minerals like limestone, clinker, phosphate, manganese, magnesite, feldspar and titanium.

More

Indicate Contributions from Several Radial VHYHQ4WRROV

For the past three decades the vertical roller mill has emerged to be the preferred choice for grinding raw materials[12]. It has advantages like low power consumption, process

More

Vertical roller mill for raw Application p rocess materials

Recently, the vertical roller mill having great grinding performance is widely applied to the raw material grinding process. However, tube mill, which has about 30% poor grinding

More

How does a vertical raw mill work?

A vertical raw mill, also known as a vertical roller mill, is primarily used in the cement industry for grinding raw materials into a fine powder. Here's a basic overview of how it operates:

More

MENGHITUNG EFISIENSI THERMAL PADA ALAT VERTICAL RAW MILL

Alfiansyah MR, dkk Menghitung Efisiensi ThermalPada Alat Vertical Raw Mill 552 Jurnal Multidisipliner Bharasumba (548-559) b) Hydraulic Cabinet Hsk (R1A04M1 Dan R1A04M2). Hydraulic cabinet berfungsi untuk menyuplai oli dengan cara memberikan gaya hidrolik agar oli dapat berpindah ke sisi piston cilinder dan sisi rod cilinder sehingga flap damper membuka.

More

Modelling of the vertical raw cement mill grinding process based

It is known that the variable is strong coupling, nonlinear, multivariable and large time-delay dynamic characteristics in the raw cement vertical mill grinding process. Against the problem which is difficult to establish accurate mathematical model, this paper establishes a production index prediction model of vertical mill raw meal grinding process by using echo state network

More

phyphar vertical raw mill

High capacity vertical grinding mill machine for Cement Slag Coal Raw Material. High Capacity. $50,000.00 - $1,000,000.00 / Set. 1.0 Sets (Min. Order) Rotary kiln. The price is very competitive. China's leading ISO9001:2008 certified high-quality rotary kiln ... Steel casting large size millstone for vertical mill. $5,000.00 - $300,000.00 / Ton ...

More

Raw mills for all requirements Gebr. Pfeiffer

The cement raw material mixtures are ground, dried, and classified in the Pfeiffer vertical roller mill. For drying the material, hot gases are directed into the mill. Product fineness can be adjusted within a wide range (0.063 to 0.2 mm).

More

Research on soft sensing of CaO in raw meal of vertical mill

Many feedback variables of the mill can provide some guidance for the regulation of raw material ratio. When the temperature difference between the inlet and the outlet of the mill is relatively stable, it is more accurate to reflect the CaO content in the raw meal through the mill variable. Take the feedback variable of the mill as input, and the CaO content as the output. The soft

More

OK™ mill The most reliable and efficient mill for raw and cement

FLSmidth has supplied the global cement industry with leading Vertical Roller Mill (VRM) designs for raw, fuel and cement grinding for several decades. The OK™ mill has been FLSmidth’s standard cement VRM since 1993. Since its introduction, the OK mill has proven to be the most efficient cement

More

Modeling Vertical Roller Mill Raw Meal Residue by Implementing Neural ...

This study proposes a method for modeling the Vertical Roller Mill (VRM) to predict residue 90 micron and residue 200 micron of the raw meal product using Back Propagation Neural Network (BPNN). The modelling step is input preparation, Artificial Neural Network (ANN) structure determination, optimizer and loss function selection, training ANN and model evaluation. In

More

Vertical roller mill for raw Application p rocess materials

Fig.2 Schematic process flow of vertical roller mill for grinding of raw materials Vertical roller mills are adopted in 20 cement plants (44 mills) in Japan. Results Table Energy saving effect of the vertical roller mill Ball mill Specific power Cost estimation

More

TUGAS AKHIR MENGHITUNG NERACA MASSA, NERACA PANAS,

tugas akhir menghitung neraca massa, neraca panas, dan efisiensi pada vertical roller mill unit rkc pt. semen indonesia (persero) tbk. pabrik tuban disusun oleh : ika fatma febriani npm : 021180021

More

Vertical Raw Mill Heat Balance Excel Sheet

HEAT AND MASS BALANCE of VRM (mill to cyclone) Date: Raw feed condition: Rate: 265: mt/h: Temperature: 35 °C: Moisture: 5.0%: Raw meal collected at cyclone: Rate 176.56: mt/h: Temperature (after cyclone) 83 °C: Moisture of

More

phyphar vertical raw mill

Phyphar Vertical Mill Raw Gitedumontnoirfr. trm vertical raw mill - postcatcher. phyphar vertical raw mill flowagency. Raw Material Vertical Roller Mill Great Wall Corporation. Vertical raw mill is a type of industrial equipment used to crush or grind materials into small particles. maintenance of vertical roller raw mill etae2016. Read More

More

OK™ mill The most reliable and efficient mill for raw and cement

FLSmidth has supplied the global cement industry with leading Vertical Roller Mill (VRM) designs for raw, fuel and cement grinding for several decades. The OK™ mill has been FLSmidth’s standard cement VRM since 1993. Since its introduction, the OK mill has proven to be the most efficient cement

More

Raw mills for all requirements Gebr. Pfeiffer

The cement raw material mixtures are ground, dried, and classified in the Pfeiffer vertical roller mill. For drying the material, hot gases are directed into the mill. Product fineness can be adjusted within a wide range (0.063 to 0.2 mm).

More

EVALUASI KINERJA VERTICAL ROLLER MILL (Cement Mill)

Pada Vertical Cement Mill terjadi empat proses yang berlangsung secara simultan. Keempat proses tersebut yaitu penggilingan, pengeringan, transport, dan separasi. Proses penggilingan, pengeringan ...

More

Coal mill, gypsum mill, clay mill, etc. Pfeiffer MPS mills

MPS vertical mill from Pfeiffer is the ideal allrounder. Grinding of coal, petcoke, clay, limestone, quicklime, gypsum, ... MPS 5000 B mill for raw material grinding, Turkey Tracim, Turkey. MPS 5300 B mill for cement raw material grinding, CDI Hail Cement, Saudi Arabia.

More

Vibration Analysis of a Vertical Roller Mill: Modeling and Validation

2014年7月25日 Vertical roller mill (VRM) is a large-scale grinding equipment, which is used to grind raw materials from block/granule into powder. Due to harsh production environment and inconsistent raw ...

More

Vertical mill casting - Magotteaux

Tire solutions for vertical mill casting . Magotteaux has the largest range of tire solutions for vertical mill casting on the market. They are available either segmented or as a monobloc. The tires or rollers are submitted to significant wear generated by the grinding and rolling actions.

More

(PDF) Menghitung Efesiensi Thermal pada Alat Vertical Raw Mill

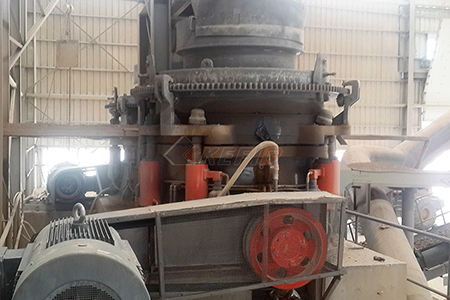

2021年12月20日 Vertical Raw Mill is a main equipment that is used in grinding or refining raw materials at PT Semen Baturaja (Persero) Tbk using a tire roller that can produce raw meal with the standard ...

Moredifférence de prix talc carbonate de calcium

- pierre de fabrication de sable de minas reglamento carrière

- projet sous ssi broyeur de pierres

- concasseur de calcaire selectionner le approprie

- Marocn broyeur de pierres

- concasseur a c ne cs norberg scs serie

- La capacité de concassage portable Chine

- Bouteille concasseur à Pretoria

- concasseur à cne cordoba

- pièces de concasseurs sayaji utilises

- Chungu Gros Concasseur A Shanghai Co Ltd

- SBM modèle moteur broyeur

- Liste des prix des moulins o

- Of Balls dans les usines de ciment principes de fonctionnement de

- broyeur de pierre primaire utilisé au royaumeuni

- propriétés fabriquées de sable