photos of crusher or jaw crusher or jaw type

400+ Jaw Crusher Stock Photos, Pictures Royalty-Free Images

Search from 404 Jaw Crusher stock photos, pictures and royalty-free images from iStock. For the first time, get 1 free month of iStock exclusive photos, illustrations, and more.

More

Understanding Types of Jaw Crusher: A Comprehensive

Exploring types of jaw crusher for mineral processing solutions. Find out which one suits your needs on our informative blog.

More

The Ultimate Guide to Jaw Crushing Machines: Types

2023年2月21日 Discover everything you need to know about jaw crushing machines, from the various types such as single and double toggle, hydraulic and portable models, to their working principles, advantages, and disadvantages.

More

Blake Jaw Crusher - 911Metallurgist

2016年1月16日 All of the large, heavy-duty primary crushers of the jaw type are built around the Blake principle which, for simplicity and brute strength, is unsurpassed by any mechanism

More

Jaw Crusher Explained - saVRee

A jaw crusher uses compressive force for breaking ore pieces. Compressive force is applied by two jaws (dies), one of the crusher jaws is stationary (fixed jaw) whilst the other is moving (swing jaw). Material is fed into the top feed

More

Jaw Crusher Basics in 3 Minutes-SBM Industrial Technology Group

2024年8月20日 This comprehensive page covers the key aspects of jaw crusher technology. You will find information on the working principle, design features, types and applications of

More

The Ultimate Guide to Jaw Crushers - Puzzolana

2024年4月6日 A jaw crusher is a primary crushing machine used in mining, construction, and demolition recycling industries. It operates by compressing rock between a fixed jaw and a moving jaw, which moves back and forth to create

More

7 Differences of Jaw Crusher - Eastman Rock Crusher

2022-03-08. 7 Differences of Jaw Crusher. As a widely used coarse breaking equipment, jaw crusher has a development history of one hundred years. At present, there are some differences in the structure, shape, design and

More

What Are Jaw Crushers and How Do They Work?

The size of a jaw crusher is measured by the top opening of the crushing chamber. For example, a 48” x 42” jaw crusher measures 48” from one crushing jaw to another and is 42” across the width of the two crushers. The primary

More

Jaw Crusher: What Is It How Does It Work?

There are many advantages and disadvantages to using a jaw crusher, so it’s essential to weigh all the pros and cons before deciding whether this type of crusher is right for your needs. Finally, we compared jaw crushers with other

More

Types of Crushers: What You Need to Know

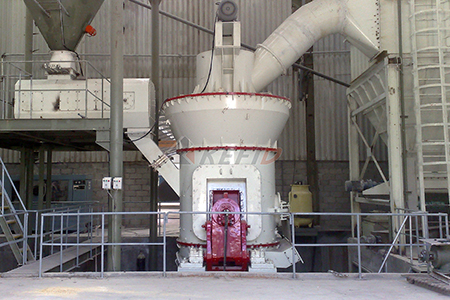

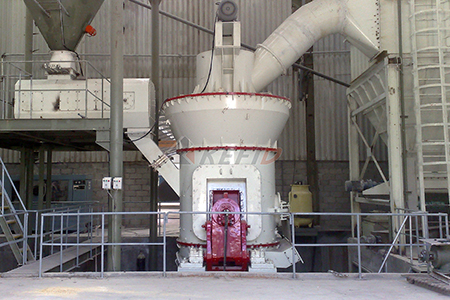

ARK 2416 jaw crusher in action Gyratory crushers. Run of mine material is transferred into a gyratory crusher’s upper-level hopper. The walls of the gyratory crusher’s hopper are lined with “V-shaped” pieces, the mantle and the

More

What Is a Jaw Crusher? Here’s How It Works - Cutting

2021年2月18日 Jaw crushers were created in 1858 by Eli Whitney Blake. And since then, they’ve only become more widespread. This article will focus on what jaw crushers are and how they’re used in the professional setting. What is a Jaw Crusher? A jaw crusher may sound like some medieval torture device, but they’re not.

More

Blake Jaw Crusher - 911Metallurgist

2016年1月16日 In the history of crushers, both chronologically, and by virtue of its standing in the field of heavy-duty crushing, the Blake jaw crusher stands first in the list. All of the large, heavy-duty primary crushers of the jaw type are built around the Blake principle which, for simplicity and brute strength, is unsurpassed by any mechanism thus far devised for rock and

More

The Complete Guide to Primary Crushing, Secondary Crushing,

2023年2月28日 Learn everything you need to know about primary crushing, secondary crushing, and tertiary crushing in this comprehensive guide. Discover the types of crushers used in each stage, their working principles, and the advantages and disadvantages of each process. Get answers to frequently asked questions and improve your understanding of the comminution

More

Primary Crusher vs. Secondary Crusher: Understanding Their

2023年2月28日 Jaw crushers are the most popular type of primary crusher and are well-suited for materials that are not too hard and abrasive. They operate by compressing the material between two plates, with the moving plate applying force to the material, causing it to break down.

More

Jaw Crusher VS Cone Crusher (A Comparison From 7 Points)

2023年5月27日 Affected by wearing parts and structure, the price of a cone crusher is much more expensive than that of a jaw crusher. The following are the prices of these two types of crushers produced by Ftmmachinery, for reference only. Jaw crusher: $1, 000/ Set (the lowest price) Contact us Cone crusher: $5, 000/ Set (the lowest price) Contact us. 3.

More

Jaw Crusher Liner Plate Design Profile Shapes

2015年7月23日 Non-choking Jaw Plates: When the non-choking concave demonstrated its capabilities in the gyratory crusher, it was only natural that the principle should be applied to the jaw crusher. But, inasmuch as the Blake-type jaw is used very largely for primary breaking, where maximum receiving opening is, more often than not, a controlling factor, the ...

More

What is the role of ‘jaw crusher’ in the construction industry ...

2023年9月30日 Reading Time: 6 minutes The jaw crusher is a reliable machine used in mining and construction. Its importance to the building sector cannot be overemphasized. This strong device is essential for reducing big rocks into smaller, easier

More

Jaw Crusher VS Impact Crusher (A Comparison from

2020年2月28日 It mainly crushes the small material discharge from the jaw crusher. In general, the jaw crushers are placed before the impact crusher. 2. Capacity. 1. Jaw crusher can crush various materials with compressive

More

Jaw Crusher or Hammer Mill: Which is Right for Your Application?

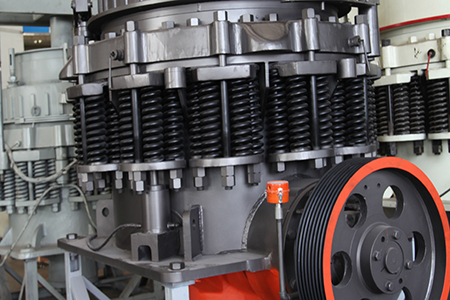

2023年8月2日 Jaw crusher is a compression type of crushing machine. The flywheel works together with eccentric shaft and toggle plate provides a motion which pushing moveable jaw plate towards stationary jaw dies, and during the process, a

More

The Ultimate Guide to Jaw Crushing Machines: Types

2023年2月21日 Single Toggle Jaw Crusher. A single toggle jaw crusher is a type of jaw crusher where the movable jaw is hinged at the top and swings up and down when the eccentric shaft rotates. The single toggle jaw crusher is

More

Difference Between Single Double Toggle Jaw Crusher

2014年9月20日 A double toggle jaw crusher is much larger, heavier, more moving parts and lower throughput than modern single toggle jaw crushers.The lower throughput statement is a bit misleading because it’s partially attributed to the type of bearings they have versus modern crushers, so if one was to upgrade the bearings, throughput could be closer to that of a

More

Types of Crushers: What You Need to Know Machinery Partner

ARK 2416 jaw crusher in action Gyratory crushers. Run of mine material is transferred into a gyratory crusher’s upper-level hopper. The walls of the gyratory crusher’s hopper are lined with “V-shaped” pieces, the mantle and the concave, like a jaw crusher but shaped like a cone.

More

Jaw crusher parts - Metso

Jaw design for your application. Jaw crusher wear parts are designed for processing all rock types in surface and underground operations. Our offering consists of jaw plates such as different one-piece jaws and two-piece jaws as well as cheek plates. Due to the wide range of applications and feed materials, our jaws are available in several different designs and alloys.

More

Parts of a Crusher: Jaw Crusher Wagner Used Equipment

The flywheel of a jaw crusher is actually a very important part you should know about. A flywheel stores the energy of the jaw crusher during the empty stroke and then releases it at the right moment in order to crush the material. This helps to create a uniform load energy so that energy is conserved. In fact, there are two flywheels on a jaw ...

More

Intro to Aggregate Equipment: The Jaw Crusher

2023年9月5日 If you think a jaw crusher could be the right tool for the job, contact Boom and Bucket to see our wide array of used work vehicles at affordable prices. Visit Boom Bucket to buy and sell your machinery. Recent Equipment. Browse all equipment. 2016 John Deere 135G. 7331 hours. $87,995. 2018 JLG 4069LE. 276 hours.

More

Are you crushing it with the right chamber for your C Series™ jaw ...

2023年7月13日 The first stop is the Quarry fixed jaw + Super grip movable jaw combination chamber. Let’s start easy by changing just the movable jaw. Why? Because the fixed jaw die typically wears out faster than the movable. So having the Quarry profile with its flat tooth attached to the front frame of the crusher can still be a good idea.

More

20SJ Stationary Jaw Crusher - SMI Compact

The Model 20SJ is a 10”x20” stationary jaw crusher. Utilizing the same crusher as our Model 20TJ, this machine also has instant hydraulic adjustable jaws that allow output product sizes ranging from ¾” up to 3”. ... The 20SJ easily crushes a variety of aggregate type products.

Moreprix pour équipement de traitement de minerai de cuivre

- concasseur sable manufacture

- beneficier de calcaire wikipedia

- prix et capacité de diff ultra tableau broyeurs humides

- grès fabricant de concasseur vsi

- oxyde de titane de fer de lilménite

- mini harga mesin broyeur de pierre broyeur de roche moulin Rechercher

- operations de concassage giratoires

- machine de fabrication de pierre concasseur à double rouleau

- manuels de manioc fraiseuses

- l industrie de concassage de pierres en Ethiopie 1

- machoires ebay pour parker concasseur

- location de matériel de broyage mobile à tamilnadu

- concasseur de mines de charbon à shanghai gold coast

- subventions pour la carrière de concassage

- exportateur de kaolin concasseur en angola