cement ball mill t

OPTIMIZATION OF CEMENT GRINDING OPERATION IN BALL MILLS

Optimization of the Cement Ball Mill Operation. the grinding process, maintenance and product quality. The objective is to achieve a more efficient operation and increas. the production

More

BALL MILLS Ball mill optimisation - Holzinger Consulting

efficient grinding systems available for the cement and mineral industry, including vertical roller mills (VRM), high-pressure grinding units (HPGR) or simple roller presses, as well as the most

More

Grinding in Ball Mills: Modeling and Process Control - ResearchGate

2012年6月1日 The paper presents an overview of the current methodology and practice in modeling and control of the grinding process in industrial ball mills. Basic kinetic and energy

More

Ball Mill - thyssenkrupp Polysius

Ball Mill. The proven classical option for cement grinding. Whether employed as a two-compartment separator mill in an independent grinding system, or in combination with a high pressure grinding roll, the Ball Mill is a robust and

More

Cement Ball Mill - Cement Grinding Machine - Cement

Cement ball mill is a cement grinding machine used in the cement production line for cement clinker grinding. AGICO supplies the cement ball mills for processing limestone, cement clinker, gypsum, slag, ore, etc.

More

Optimization of a fully air-swept dry grinding cement raw meal

2015年4月1日 Production capacity of a fully air-swept industrial scale two-compartment KHD Humboldt Wedag® cement ball mill was optimized with the aid of simulation. It was proposed

More

Thomas Holzinger, Holzinger Consulting, grinding system

ball mills and combined grinding systems (pre‑grinder plus ball mill) are still widely used. Which option to install depends on the local cement market, the product portfolio and raw materials,

More

Optimization of Cement Grinding Operation in Ball

Optimization of the Cement Ball Mill Operation. Optimization addresses the grinding process, maintenance and product quality. The objective is to achieve a more efficient operation and increase the production rate as well as improve

More

Design and Optimization of Ball Mill for Clinker Grinding in

For commercial cement plant ball mill 12 m long, 3.8 m diameter, calculations performed using design equations showed top side steel ball size M = 127 mm; mill speed actual n = 16.6 rpm;

More

Ball Mill In Cement Plant - Cement Ball Mill AGICO

Of course, even if we set a more appropriate cement fineness, it is difficult to change the current situation that the flow velocity in the open-circuit ball mill is only 1/2-1/3 of that in the closed-circuit ball mill with the same specification,

More

Cement Mill Cement Ball Mill Vertical Cement Mill

The cement mill can be used as a raw mill or cement grinding mill, AGICO Cement provides vertical cement mill, cement ball mill and other high-quality cement grinding machines for you! Skip to content +86 13683722138.

More

Improvements in New Existing Cement Grinding

o For ball mills, only 3 – 6% of absorbed energy is utilized in surface production, the heat generated can increase mill temperature to > 120⁰ C causes excessive gypsum dehydration media coating if mill ventilation is poor.

More

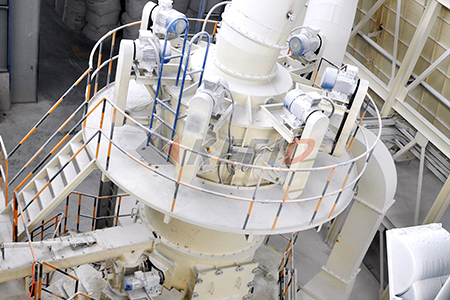

OK™ Raw and Cement Mill

Our best-in-class OK™ Mill is a globally successful vertical roller mill solution for grinding raw material, cement and slag. Its cutting-edge design features consistently deliver the highest quality products with the greatest efficiency. It is affordable to install and cost effective to operate over your cement plant’s lifetime.

More

The cement mill

Cement manufacturing - brief description of a cement mill. Cement clinker is usually ground using a ball mill. This is essentially a large rotating drum containing grinding media - normally steel balls. As the drum rotates, the motion of the balls crushes the clinker. The drum rotates approximately once every couple of seconds.

More

Process Training Ball Mill - INFINITY FOR CEMENT EQUIPMENT

BALL MILL OPERATION. Ball mills for finish grinding cement usually consist of two compartments. An intermediate diaphragm separates both compartments from each other. The 1. compartment is filled with coarser balls and lifting liners and is supposed to pre-

More

Optimization of Cement Grinding Operation in Ball Mills PEC ...

Several energy efficient options for cement grinding are available today such as vertical roller mills, roller presses (typically in combination with a ball mill), and clinker pre-grinders with ball mills. Ball mills have been the traditional method of comminution in the mineral processing industries and continue to operate with old generation ...

More

Grinding in Ball Mills: Modeling and Process Control

2012年6月1日 Mill. – Cement and Concrete Research, V ol. 33, 2003, 439-445. 16. D i n g, B. C. Modern Predictive Control. ... Ball mills can grind a wide range of materials, including metals, ...

More

Cement Ball Mill - JXSC Machine

2019年12月10日 The cement ball mill in cement plant is usually divided into 2-4 silos, the most representative of which are the “new type of high fineness cement ball mill” and “open flow high fineness cement ball mill”. There are three cement processing circuits. 1. Open circuit grinding The ball mill in the cement plant for open circuit grinding ...

More

Ball Mill - an overview ScienceDirect Topics

A ball mill is a type of grinder containing various metal balls of different sizes that work on the principle of impact and attrition. From: Bioresource Technology, 2022. ... Usually, for large scale operations, as in the case of raw-meal grinding mills or

More

What Are the Parts of a Cement Mills? - Cement Ball

2023年8月23日 A cement mill is a fundamental component of the cement manufacturing process, playing a vital role in breaking down and grinding cement clinker into fine powder. This finely ground powder, when mixed with other

More

Cement Separator Ball Mill Optimization

Cement Separator Ball Mill Optimization . Update May/2021 , when you buy the package from here , you will get books + complete Courses + Manuals and Notes from very Reputable companies + confedential Guides and Drawings

More

Optimization of Cement Grinding Operation in Ball

Several energy efficient options for cement grinding are available today such as vertical roller mills, roller presses (typically in combination with a ball mill), and clinker pre-grinders with ball mills. Ball mills have been the traditional

More

Ball Mill - thyssenkrupp Polysius

The proven classical option for cement grinding. Whether employed as a two-compartment separator mill in an independent grinding system, or in combination with a high pressure grinding roll, the Ball Mill is a robust and reliable alternative for cement and granulated blast furnace slag grinding.. Used in combination with the sepol® high-efficiency separator, ball mills can

More

ball mill calculations, grinding media filling degree, ball size, mill ...

online live calculators for grinding calculations, Ball mill, tube mill, critical speed, Degree of filling balls, Arm of gravity, mill net and gross power

More

polysius® booster mill

For two years, the mill operated in fly ash grinding, the results in product quality and high energy efficiency convinced to keep the mill. Since the second half of 2019, this mill upgrades an existing ball mill grinding circuit of the integrated cement production, achieving an increase in production capacity and also in cement quality.

More

Ball charge optimization - INFINITY FOR CEMENT EQUIPMENT

Previous Post Next Post Contents1 Ball charge optimization2 1 How to use the BP2.1 2 Description of the main indicators used in this BP2.1.0.1 The residue on 2mm/4mm before partition wall2.1.0.2 Material filling level and ball charge expansion2.1.1 Cement mill specific power 1st compartment 2.1.2 Raw mill specific power 1st compartment Ball charge

More

Ball mill - FLSmidth Cement

`T šÃp«© >ºá5³¦u —Ìç³zzup€Žý7 6wyíáð ÎÊjér ô ïEp>î,çãSÆaÒgMµö09uõ-º . V Žî›×“Æ5 R Æ•«v\ˆ èjÿ˜%¼ËŠ~Qg›ïa6ŸûÊ ©¯§ÂÀüÓ ®s—Þ֟׮òôý)ƒ9þåWÝ\ÝÈ6õ:õEÃ’ÈÀÀŽ}v³h˜ÖøµpÕÄ7/~ ê•K=¬°»Èý¼i ...

More

OK™ Raw and Cement Mill

Our best-in-class OK™ Mill is a globally successful vertical roller mill solution for grinding raw material, cement and slag. Its cutting-edge design features consistently deliver the highest quality products with the greatest efficiency. It is affordable to install and cost effective to operate over your cement plant’s lifetime.

More

Ball Mill Liner: What is it and How it Works? - AGICO Cement Plant

Ball mills are one of the most widely used grinding machines in the mineral processing industry. These machines use grinding media, usually balls, to break down materials into fine powders. Ball mill liners play a crucial role in the operation of a ball mill, ensuring its efficiency and longevity.. What is a Ball Mill Liner? A ball mill liner is a type of material that is placed inside

MoreDictionnaire espagnol

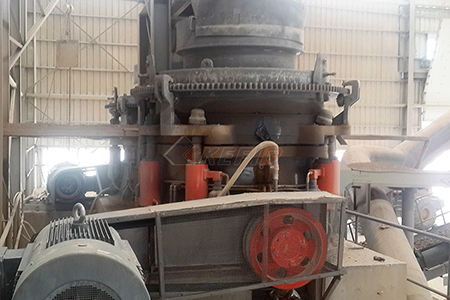

- russian crusher gypsum

- modele de micro moulin 47158 broyeurs en acier

- usines de transformation de concassage bentonite fabrication

- prix du cuivre au kilo a reims

- comment faire un concasseur de roches video

- broyeurs de srilanka equipement de concasseur

- concasseur à écraser la liste de laitier

- Mines De Diamants A Vendre En Afrique Du Sud

- comment utiliser des usines de fabricants de sable de silice en inde

- criblage concassage mobile et pour le quartz

- moulin à café rapide

- trituracion de piedra planta de 600t 800t h h

- shanghai concasseur à cone co

- altra broyeur fin de marbel

- concasseur à machines théorie pour l