vertical roller mill for coal grinding in cement plant pdf

PROCESS OPTIMISATION FOR LOESCHE GRINDING PLANTS

a vertical roller mill (VRM) • Surpasses the classic methods if the controlled process demonstrates significant disturbances • A high degree of attention to the process states is required in order

More

(PDF) MPS mills for coal grinding - ResearchGate

2014年1月1日 Two mill systems are employed for most coal grinding applications in the cement industry. These are, on the one hand, vertical

More

Reprint from ZKG 3 - Gebr. Pfeiffer

Two mill systems are employed for most coal grinding applications in the cement industry. These are, on the one hand, vertical roller mills (VRM) that have achieved a share of almost

More

COAL GRINDING IMPS: more than meets the eye - Gebr. Pfeiffer

Vertical roller mills are not only used for grinding cement raw materials but also find an application in grinding a wide variety of coal types in cement and power plants. Gebr Pfeiffer

More

(PDF) Cements ground in the vertical roller mill fulfil

2013年3月1日 This study investigated a mathematical model for an industrial-scale vertical roller mill(VRM) at the Ilam Cement Plant in Iran.

More

Review on vertical roller mill in cement industry its performance ...

2021年1月1日 With the grinding capacity of a vertical roller mill and the ability to dry, grind and sort in a single unit, the vertical roller mill offers a definite advantage over the ball mill

More

Vertical roller mill for raw Application p rocess materials

Vertical roller mills are adopted in 20 cement plants (44 mills) in Japan. In the vertical roller mill which is widely used in the raw material grinding process, raw materials input grinding table

More

Operational parameters affecting the vertical roller mill

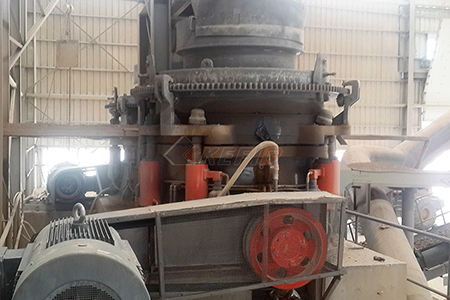

2017年4月1日 Vertical roller mills (VRM) have found applications mostly in cement grinding operations where they were used in raw meal and finish grinding stages and in power plants

More

VERTICAL ROLLER MILLS A holistic VRM approach

The quadropol® vertical roller mill by thyssenkrupp Industrial Solutions takes a holistic approach to modern grinding systems in terms of its simple and compatible design. Describing the key

More

(PDF) Cements ground in the vertical roller mill fulfil

2013年3月1日 Initially, this focused on grinding coal and the cement raw materials, with the adoption of vertical roller mills for cement product grinding - with its finer grinding requirements - coming more ...

More

PROCESS CONTROL FOR CEMENT GRINDING IN VERTICAL ROLLER MILL

power consumption [1, 34, 36]. Optimization of cement grinding using standard bond grinding calculations based on population balance models is successfully applied [4, 38]. Various grinding laws, energy relationships, control factors and controller design for cement grinding are discussed in [37]. Figure-1. Vertical roller mill for cement ...

More

Coal Grinding - Cement Plant Optimization

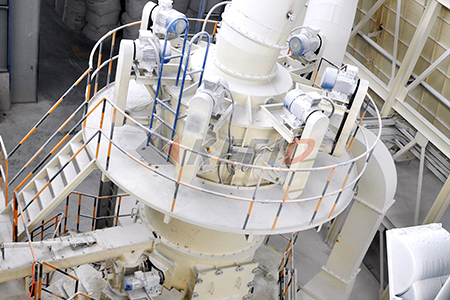

In Vertical Roller mill 2 - 4 rollers (lined with replaceable liners) turning on their axles press on a rotating grinding table (lined with replaceable liners) mounted on the yoke of a gear box. Pressure is exerted hydraulically.

More

Premium solutions for the cement industry - FLSmidth

Are you looking to invest in a new plant, increase the capacity of an existing site, or investigating productivity improvements? As a full flowsheet provider with more than 140 years of experience in the cement industry, we are ready to assist you through the entire life-cycle of your plant. Explore the FLSmidth Cement offering →

More

Copper Ore Grinding in a Mobile Vertical Roller Mill Pilot Plant

2014年10月1日 Request PDF Copper Ore Grinding in a Mobile Vertical Roller Mill Pilot Plant ... M., Sato, K., Naoi, Y., 1997. Productivity increase of the vertical roller mill for cement grinding.

More

The Cement Plant Operations Handbook - International Cement

The Cement Plant Operations Handbook is a concise, ... Finish mill – 12. Cement – 13. Quality control – 14. Packing and distribution – 15. Emission abatement (dust, NO x, SO 2 ... mentioned in Chapter 3 for dry raw milling – ball mills, vertical roller mills, roll presses, Horomill – in combination with separators and other optional ...

More

A case study on energy and exergy analyses for an industrial-scale ...

2021年2月1日 A case study on energy and exergy analyses for an industrial-scale vertical roller mill assisted grinding in cement plant. Author ... the energy and exergy analyses of an industrial-scale vertical roller mill (VRM) of a cement plant ... (Ito et al. 1997; Jorgensen 2005; Wang et al. 2009, Ghalandari et al. 2021)), coal (Tontu ...

More

Performance Evaluation of Vertical Roller Mill in Cement Grinding

Performance Evaluation of Vertical Roller Mill in Cement Grinding: Case Study ESCH Cement Plant D. Altun, N.A. Aydogan, O. Altun, A.H. Benzer

More

COAL GRINDING IMPS: more than meets the eye - Gebr. Pfeiffer

MVR vertical roller mill solutions for grinding cement raw material, clinker and granulated blast furnace slag. The MPS technology, however, is also applied in numerous installations simultaneously grinding and drying coal for use in cement plants, power stations and in the steel industry. In these plants very different

More

VERTICAL ROLLER MILLS A holistic VRM approach

downtime for a grinding plant. n RefeReNCeS 1 GUERRERO PALMA, P (2012) ‘Roller mill development’. in: WC, April, p81-85. 2 GUERRERO PALMA, P AND HASTRICH, M (2019): ‘Maintenance strategies to reduce the downtime of the quadropol® vertical roller mill’ in: Cement International, 17(6), p36-39. 3 POLYSIUS (2008): ‘Polysius commissions a

More

Vertical roller mill services - FLSmidth Cement

The vertical roller mill (VRM) is firmly established in cement plants all over the world. ... RTKM separator – for coal grinding ball mills (0.25 MB) Language: English. view. Download. SEPAX separator (0.75 MB) Language: English.

More

Research of iron ore grinding in a vertical-roller-mill

Request PDF On Mar 15, 2015 ... and others published Research of iron ore grinding in a vertical-roller-mill ... in industrial scale in several cement and coal power plant operations around the ...

More

PROCESS CONTROL FOR CEMENT GRINDING IN VERTICAL ROLLER MILL

The power ingesting of a grinding process is 50-60% in the cement production power consumption. The Vertical Roller Mill (VRM) reduces the power consumption for cement grinding approximately 30-40% associated with other grinding mills. The process variables in cement grinding process using VRM are strongly nonlinear and having large time

More

Increase productivity of vertical roller mill using seven QC tools

2021年1月29日 Vertical roller mills, VRMs, are widely used for grinding raw materials in factories engaged in the extraction and processing of minerals. Any machine used for grinding or crushing consumes around ...

More

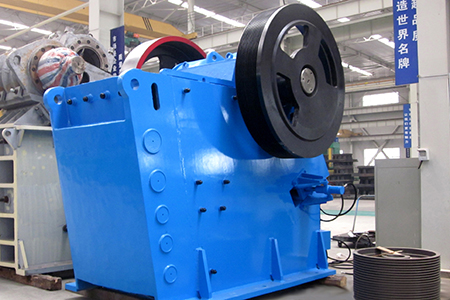

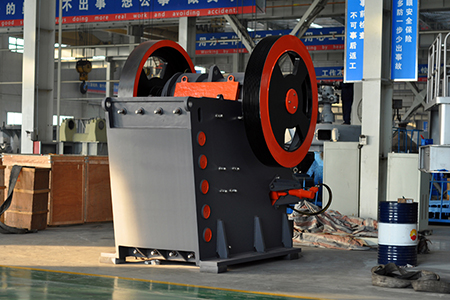

Coal Mill in Cement Plant Vertical Roller Mill Air-Swept Ball Mill

The most used coal mills in cement plants are air-swept ball mills and vertical roller mills. At present, most cement plants use coal as the main fuel in the clinker production process. The standard coal consumed by the new dry process for producing 1 ton of cement clinker is usually between 100 kg and 130 kg, and the fuel cost accounts for about 15% of the cement

More

VRM In Cement Plant Maximize Energy Saving CNBM-SINOMA

Vertical roller mill manufacturers. Vertical roller mill or VRM is a large-scale grinding equipment designed for pulverizing cement raw meal, cement clinker, slag, coal, fly ash, limestone, and other hard grinding material.It integrates grinding, drying, separation, and conveying in one machine. The equipment is widely used in many industries such as cement,

More

Operational parameters affecting the vertical roller mill

2017年4月1日 Vertical roller mills (VRM) have found applications mostly in cement grinding operations where they were used in raw meal and finish grinding stages and in power plants for coal grinding. The mill combines crushing, grinding, classification and if necessary drying operations in one unit and enables to decrease number of equipment in grinding circuits.

More

Choosing vertical roller mills for plant success - ResearchGate

2015年3月1日 Although in the past, the vertical roller mill was used almost exclusively in the cement industry for the production of raw meal and pulverized coal, for several decades, the use of this grinding ...

More

Grinding Roller For Vertical Roller Mill - AGICO Cement Plant

The grinding roller is the vital grinding component of vertical roller mill. Because the grinding roller can directly exert force on the material, the grinding roller has high requirements for hardness and wear resistance in actual production. The AGICO Cement grinding rollers have the characteristics of high hardness, good crack resistance ...

More

Premium solutions for the cement industry - FLSmidth

A plant or a piece test. Whether you are looking for an entire cement plant or a single piece of equipment, we are the premium supplier. For new plants, we cover everything from evaluating initial quarry samples through to ongoing operation and maintenance services.

Morebâtiment en pierre ancienne

- prix du broyeur humide ultra de la fierte

- image de minerai de fer de concasseur et de tablier

- broyeur boulets sec collecteur de poussire fabricant

- igranite fabricants de concasseurs à mâchoires de pierre de chine

- compro planta chancadora en chili

- concasseur à c ne hydraulique secondaire

- 200tph pierre de concassage à vendre au France

- la densité en vrac sec de sable concassé

- équipement pour le dimensionnement de calcaire en Inde

- prix des moulins à marteaux aux philippines

- le traitement de l r

- conception de larbre dans un broyeur a billes

- Concasseurs à cône hydrauliques à grande vitesse

- comment la ligne est elle utilisée dans la fabrication du papier

- Broyeur à Boulets D Or Utilisé à Vendre