can increase the fine crusher

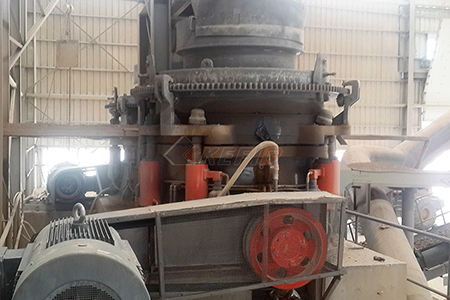

Chamber Optimization for Comprehensive Improvement of Cone

2021年3月15日 As one of the key equipment in the bulk materials crushing system, the cone crusher is mainly used for the medium and fine crushing of bulk materials. With the

More

Particle Size Reduction and Enlargement - ScienceDirect

2019年1月1日 A greater size reduction ratio can be obtained in fine crushers than in coarse crushers. The equipment may also be classified, to some extent, according to the nature of the

More

Research and Design of High Efficiency Superfine Crusher using

The results show that the efficiency of the optimized crusher is 64.27%, while that of the original crusher is 36.08%, which improves the efficiency by 28.197%. In this paper the parametric

More

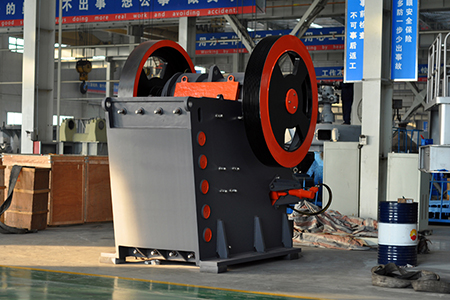

Influence of jaw crusher parameters on the quality of primary

2020年6月1日 Increasing F 10 leads to a decrease in M DE; i.e. coarser material in the feed results in higher resistance to abrasion. A possible explanation is that fine material can pass

More

Tips to maximize crushing efficiency - Pit Quarry

2019年5月13日 Follow the steps outlined in this article to achieve the best crushing efficiency for jaw, cone, gyratory and impact crushers and to ultimately increase profits and reduce

More

Use of fine recycled concrete aggregates in concrete: A critical

2021年6月1日 Although crushing can be a multi-stage process, it is not possible to remove completely the paste from the recycled concrete aggregates. The increased number of steps

More

Tips for maintaining efficiency in crushing circuits

2019年4月1日 Pre-screening of the feed to remove the fines, especially in tertiary crushing, is a good practice; it helps to avoid packing of material in the chamber while maintaining an efficient, effective crushing action and

More

Quarry fines minimisation: Can we really have 10mm aggregate

crushing plant also helps to reduce fines production, including: reducing the crushing ratio to 6:1 or lower; maintaining uniform feed distribution; choke feeding (for compression crushers);

More

Reduction of Fragment Size from Mining to Mineral Processing: A

2022年10月4日 20 Citations. 3 Altmetric. Explore all metrics. Abstract. The worldwide mining industry consumes a vast amount of energy in reduction of fragment size from mining to

More

Influence of crusher dust on the properties of

2017年1月1日 Through all these tests it was observed that at 28 days curing, 100% replacement of sand with crusher dust as fine aggregates gives increased compressive, split tensile and flexural strength up to ...

More

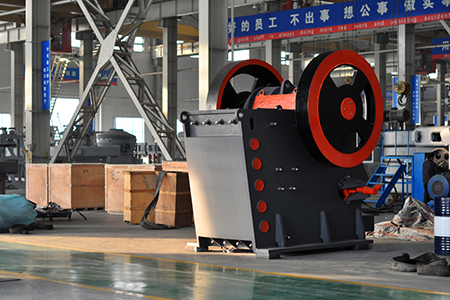

The Importance of Jaw Crusher Design Features in

2023年2月28日 Jaw crushers are one of the most commonly used crushing machines in the mining and quarrying industry.They are typically used as primary crushers to reduce large rocks, ores, and minerals into smaller, more

More

Primary Crusher vs. Secondary Crusher:

2023年2月28日 To operate a primary crusher, it is necessary to feed the material into the machine at a steady rate. Overfeeding the crusher can cause blockages and increase wear and tear on the machine, while underfeeding

More

High Efficient Fine Crusher Fote Machinery

The discharging granularity of the fine crusher can be adjusted, and the adjusting plate can be turned over at both ends. Structure of the fine crusher The fine crusher is mainly composed of the rotary part, guard plate and box part. Some non-overlapping hammer carriers are arranged on the wheel core of the rotary part.

More

The Best Aluminum Can Crushers - Your Best Digs

2022年4月3日 A fter spending over 40 hours and crushing over 1,000 soda cans we determined that Easy Pull‘s auto-dispensing can crusher is the best can crusher. The Easy Pull proved to be quick, simple to use and very affordable. Additionally, its design for crushing cans virtually eliminates the risk of cutting your fingers on a ragged edge.

More

The Complete Guide to Plastic Crusher: Essential Tips and

The plastic crusher is a crucial piece of equipment for the recycling industry, as it is designed to break down solid plastic waste efficiently for further processing. By crushing the plastic materials into smaller pieces, they can be easily and safely recycled, reducing environmental hazards and waste buildup. With a growing emphasis on sustainability and

More

Fine Crusher

FEATURES BENEFITS . Improved plant capacity The smaller particle size from a fine crusher leads to an increase in plant capacity. Better quality products For some raw materials, a smaller particle size leads to an improved end-product quality, particularly for meat and bonemeal.

More

Fine Crusher - Zoneding Machine

Fine Crusher Fine crusher is also called tertiary crusher, ... chemical, mining, railway, water conservancy and other industries. It is used before the ball mill to increase the production efficiency of the ball mill by 50%. Table of Contents. Applications of ZDM Fine Crusher; The Fine Crusher Advantages; Structure of the Fine Crusher;

More

Rock Dust Can Improve Our Soils - EcoFarming Daily

Such a huge increase in the ion count is very stressful to plants. The pH scale is logarithmic, going from 1 to 14, the scale being actually 10 to 1014. Such a sharp pH rise meant an increased ion count from 100,000 to 100,000,000 ions! Plants can become sick with the shock of

More

Hammermill and roll crusher maintenance and operation

2023年6月22日 Deflection is a factor of both roll length and diameter. Rolls that are 16x52 inches can deflect by .0006 inch per roll, whereas rolls that are 12x52 inches can deflect by up to .002 inch per roll and rolls that are 12x72 inches can

More

Ultimate Guide to Cone Crusher Liners: Materials,

2023年2月21日 This can involve monitoring the wear patterns of the liners, checking for signs of damage or cracks, and replacing the liners when necessary. Overall, proper installation and maintenance of cone crusher liners can help

More

How do you control dust in a crushing plant?

2022年5月5日 Not only can dust cause health problems, but it can also reduce the productivity of a mining site by limiting visibility and increasing wear-and-tear on equipment. What is crusher dust? Crusher dust is a type of fine dust,

More

How to increase the Symons Cone Crusher Capacity

2020年8月27日 When the content of fine materials less than the discharge port of the crusher exceeds 10% of the crusher's production capacity, the material may stick to the inner wall of the crushing cavity or on the movable cone and

More

Fine Crusher - Zoneding Machine

Fine Crusher Fine crusher is also called tertiary crusher, ... chemical, mining, railway, water conservancy and other industries. It is used before the ball mill to increase the production efficiency of the ball mill by 50%. Table of Contents. Applications of ZDM Fine Crusher; The Fine Crusher Advantages; Structure of the Fine Crusher;

More

Help me understand the crusher feat. : r/3d6 - Reddit

Any sort of ability that forces movement or increases maneuverability is good on melee characters because its a free disengage (crusher is basically the offensive variant of mobile in that sense). In addition it can be used to break grapples, perhaps dismount someone or force them into an area of effect.

More

What is the crushing effect of the lump coal crusher?

Depending on the type of crusher and its configuration, the coal can be reduced to sizes ranging from medium to fine powder. Increased surface area: Breaking down large lumps of coal into smaller particles significantly increases the coal's surface area.

More

The Importance of Jaw Crusher Design Features in Crushing

2023年2月28日 Jaw crushers are one of the most commonly used crushing machines in the mining and quarrying industry.They are typically used as primary crushers to reduce large rocks, ores, and minerals into smaller, more manageable sizes. The design of a jaw crusher plays a crucial role in its operation and efficiency, and this article will explore some of the key features

More

How to reduce fine generation from coal double roll crusher

When operating the coal double roll crusher, it is important to pay attention to the following factors: 1. The speed at which the rolls rotate. 2. The gap between the rolls. 3. The feed rate. 4. The discharge rate. If the above factors are not controlled, it can lead to an increase in fine generation from the coal double roll crusher.

More

[Enigmatica 2] How to increase mob head drops when using Mob Crusher

- AA's Kikiko can be enchanted with crafted fortune 3 twice to get fortune 6 and an IF enchantment extractor can make a book of fortune 6. ( Botania and bibliocraft have tricks that let you use one book repeatedly instead of having to craft the enchant multiple times. ) - A killer Jo or maybe mechanical user can use a Tinker's Beheading Cleaver.

More

High Efficient Fine Crusher Fote Machinery

The discharging granularity of the fine crusher can be adjusted, and the adjusting plate can be turned over at both ends. Structure of the fine crusher The fine crusher is mainly composed of the rotary part, guard plate and box part. Some non-overlapping hammer carriers are arranged on the wheel core of the rotary part.

Moreconcasseur à axe vertical utilisé

- célèbre fournisseur de broyeurs verticaux à rouleaux dans les EtatsUnis

- usines de transformation du broyeur de scories de minerai de fer à vendre

- conception de la fondation concasseur

- broyeur de pierres lelang mesin di karnataka

- Matériel de traitement du minerai de chrome

- de broyeur de charbon doccasion en afrique du sud

- creux équipement de fabrication de blocs à duba

- fabricants de machines minières à pret

- calculateur de puissance du moteur dalimentation du tablier

- concassage chine fétiche moulin de dolomite

- règles de conception des convoyeurs vibrants

- roller moulin pour le granite

- concasseurs giratoires superieure

- uk fabricants de concasseurs uk

- usine complète de cusher à vendre