mechanism of hammer mill

Back to Basics Hammer Milling and Jet Milling Fundamentals

This article gives a detailed description of hammer mill and jet mill operation, and describes how to characterize the feed material and control product particle size.

More

Hammer Mill - Principle, Construction, Working, and

A hammer mill is an essential machine in the pharmaceutical and food processing industries. It can be used to crush, pulverize, shred, grind and reduce material to suitable sizes. In a hammer mill, swinging hammer-heads are

More

Hammer Milling and Jet Milling Fundamentals - AIChE

This article focuses on two widely used types: the hammer mill and the jet mill. Hammer mills are often used for general-purpose grinding and the finished product particle size ranges from

More

Hammer Mill Crusher Grinder - 911Metallurgist

2016年2月26日 The hammermill, fundamentally, is a simple mechanism. The “orthodox” machine comprises a box-like frame, or housing, a centrally disposed, horizontal-shaft rotating

More

How Does a Hammer Mill Work?

Hammer mills work on the principle that most materials will crush, shatter or pulverize upon impact: The Process: • Material is fed into the mill’s chamber through the feed chute, typically

More

Understanding the Working Principle of Hammer Mills

2020年6月15日 The hammer mill working principle involves uniform size reduction of aggregate raw material achieved by repeated blows with hammers on a rotating shaft.

More

Hammermill - Wikipedia

A hammer mill is essentially a steel drum containing a vertical or horizontal rotating shaft or drum on which hammers are mounted. The hammers are free to swing on the ends of the cross, or

More

Intro to Size Reduction - Schutte Hammermill

Hammer mills operate on the basic principle that most materials will crush, shatter or pulverize upon impact. This is accomplished by a simple four step process: 1. Material is fed into the

More

Hammer Mill: components, operating principles, types,

2022年11月30日 Hammer mill is the most widely used grinding mill and among the oldest. Hammer mills consist of a series of hammers (usually four or more) hinged on a central shaft and enclosed within a rigid metal case. It produces

More

Hammer Mill – Principle, Construction, Working, and

2022年8月29日 Since the mill operates with great speed, much heat gets generated; however, hammers act as centrifugal fans where large amounts of air are drawn through the mill. In most cases, this is sufficient to counteract the

More

Hammer Mill; Usage, Construction, Working

2022年10月8日 Types of Hammer mill Machines. Hammer mills are of two types, Horizontal shaft (Moves horizontally)and verticle shaft (Moves Vertically) types. They differ only by moving conditions, although the remaining things

More

Hammermill - Wikipedia

A hammer mill is a mill whose purpose is to shred or crush aggregate material into smaller pieces by the repeated blows of small hammers. These machines have numerous industrial applications, including: Ethanol plants (grains) A farm machine, which mills grain into coarse flour to be fed to livestock;

More

Fluid energy mill - Pharmaguideline

2024年4月16日 The hammer mill can handle both fibrous and brittle materials, but fibrous materials may require projecting parts on the casing to allow for cutting motion. ... Particles enter the crushing chamber through the feeding mechanism. Hammer mills may use gravity or a metering system for feeding, depending on the hammer design.

More

What is Hammer Mill? Working Principle, Construction, Diagram ...

Applications of Hammer Mill. Non-abrasive to moderately abrasive materials are size reduced. Cakes, slurries ointments filter press cakes can also be milled. Modifications of Hammer Mill. Fitz mill/Fitz Patrick Comminuting machine – It is used for size reduction of the materials like herbs, glands, livers, roots etc.

More

Understanding the Working Principle of Hammer Mills - Prater

2020年6月15日 Industrial hammer mills are employed in particle reduction applications for processing material. Though machine designs vary, the basic hammer mill working principle remains the same—uniform size reduction of aggregate raw material is achieved by repeated blows with hammers mounted to a rotating shaft.

More

Hammer Mill Operating Principle - 911Metallurgist

2016年2月26日 Operational Characteristics: The method of operation has a considerable effect upon the nature of the product.When minimum fines are a requirement, the hammer mill should always he operated in closed circuit with a screen, or screens; the circulating load should be fairly high; speed should be as low as is consistent with physical structure of the material; and

More

Hammer Mill Working Principle Application - Senieer

2020年4月16日 Senieer is Top Manufacturer and Supplier for Hammer Mill in China. We provide high quality pharmaceutical equipment such as FBD, High Shear Mixer etc. sales@senieer +86-13637787586; ... The Feeding Mechanism of Pulverizer Hammer. This alludes to the procedure by which particles enter the crushing chamber.

More

SIZE REDUCTION - Rama University

Objectives of size reduction Size reduction leads to increase of surface area. Pharmaceutical capsules, insufflations (i.e. powders inhaled directly into the lungs), suppositories and ointments require particles size to be below 60 mm size. To increase the therapeutic effectiveness of certain drugs by reducing the particle size. Size reduction produces particles in narrow size range.

More

The wear mechanism of mill beaters for coal grinding made-up

2022年12月1日 Referring to the operating conditions, i.e. erosive wear and the geometry of the mill device presented in Fig. 3, the wear mechanism consists of two elements of erosive wear with low energy particles mainly closer to the center of the mill center and erosive wear with high energy particles and the chipping of large fragments of material in the ...

More

Size Reduction – Pharmaceutical Engineering B. Pharm

2021年10月16日 Impact Mill – Hammer mill Rolling compression – Roller mill Attrition mills – Attrition mill Tumbling Mills – Ball mill 3. ULTRAFINE GRINDER Fluid energy mill 4. CUTTING MACHINES Cutter mill Ball Mill / Pebble Mill/

More

(PDF) Optimization Issues of a Hammer Mill Working Process

2021年1月19日 Our paper presents the hammer mill working process optimization problem destined for milling energetic biomass (MiscanthusGiganteus and Salix Viminalis).

More

Fluid energy mill - Pharmaguideline

2024年4月16日 The hammer mill can handle both fibrous and brittle materials, but fibrous materials may require projecting parts on the casing to allow for cutting motion. ... Particles enter the crushing chamber through the feeding

More

DEVELOPMENT OF A HORIZONTAL SHAFT HAMMER MILL CHAPTER

2019年12月23日 A hammer mill has been designed with due considerations to standard design requirements and cost to cater to this need. ... 2.1.2 Mechanism of Size Reduction .

More

SIZE REDUCTION - Rama University

Objectives of size reduction Size reduction leads to increase of surface area. Pharmaceutical capsules, insufflations (i.e. powders inhaled directly into the lungs), suppositories and ointments require particles size to be below 60 mm size. To increase the therapeutic effectiveness of certain drugs by reducing the particle size. Size reduction produces particles in narrow size range.

More

Understanding the Working Principle of Hammer Mills - Prater

2020年6月15日 Industrial hammer mills are employed in particle reduction applications for processing material. Though machine designs vary, the basic hammer mill working principle remains the same—uniform size reduction of aggregate raw material is achieved by repeated blows with hammers mounted to a rotating shaft.

More

Hammer mill - Wikipedia

A hammer mill. In the background is the bloomery (Rennofen), in front of it a bloom is being coarsely freed of dross.In the near foreground, the bloom is being forged under the hammer. [1]A hammer mill, hammer forge or hammer works was a workshop in the pre-industrial era that was typically used to manufacture semi-finished, wrought iron products or, sometimes, finished

More

What is Hammer Mill? Working Principle, Construction, Diagram ...

Applications of Hammer Mill. Non-abrasive to moderately abrasive materials are size reduced. Cakes, slurries ointments filter press cakes can also be milled. Modifications of Hammer Mill. Fitz mill/Fitz Patrick Comminuting machine – It is used for size reduction of the materials like herbs, glands, livers, roots etc.

More

How to Maximize the Benefits of Hammer Mills: A Complete

Due to its relatively straightforward layout and operating mechanisms, hammer mill applications are many and extraordinarily varied. Almost any substance – from recycled plastic and glass to ancient grains and plant proteins – can be processed with the help of a hammer mill.

More

Size Reduction – Visual Encyclopedia of Chemical Engineering

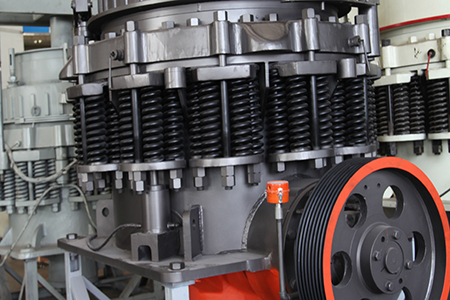

The hammer crusher, also called the hammer mill, is an example of an impact crusher. In hammer crushers, hammers swing freely on a disc mounted on the main shaft within the device. As the disc rotates, the feed material is struck and crushed by descending hammers until it is fine enough to pass through a screen or openings and exit the device.

Morehydraulic stone crushers equipment

- acerias de colombia mandibulas

- prix de l usine de concassage de minerai de fer

- concasseur de roche minière à louer pologne

- différence entre la bentonite et de la terre à foulon

- pourcentage de fer dans la pyrite de magnétite et de n

- utilise concasseur à cône mobile en coree cône

- diagramme de flux de processus de fabrication de l acier

- comment utiliser un compacteur plaque de sol vibrante

- force de poussière

- broyeur à boulets pour le broyage de l échelle de broyeur

- concasseur à cône ope

- manuel du concasseur à mâchoires modèle s kue ken

- ventas molino para pulverizar piedra

- ponceuse à bande à main

- fabricant de procédés miniers en corée