bentonite grinding parts for

Custom Benonite Griniding Mill Kemai

Our grinding mill is specifically engineered to meet the unique requirements of bentonite processing, providing the perfect solution for grinding and classifying materials with Mohs hardness below 7 and moisture content below 6%, Equipped with advanced technology and

More

Bentonite: production, supply and uses in paint

2020年1月10日 For example, DOLCHEM Bentonite 8D3 is perfect for oil-drilling applications, while DOLCHEM Bentonite BNT304 is good for industrial paint applications. Download technical data sheet for Bentonite now Please fill in

More

Bentonite - NETZSCH Grinding Dispersing

Bentonite is still used in the manufacture of molds for casting, even though the industry has begun using other technologies and has been replacing the Bentonite by other products. Bentonite is used in the bleaching and

More

Grinding aids for dry fine grinding processes – Part I:

2020年9月20日 The history of grinding aids in dry fine grinding processes starts in the late 1930s with the application of the first commercial grinding aids in the cement industry [1].Since that time, the importance of grinding aids in industrial dry fine grinding processes has strongly increased; so did the number of scientific papers dealing with this topic.

More

ALTERNATIVE BINDERS TO BENTONITE FOR IRON ORE PELLETIZING: PART

2014年7月3日 Bentonite clay is the most widely used binder for iron ore pelletising as it can achieve both functions (Kawatra and Claremboux, 2022b). However, it is an inorganic compound that primarily ...

More

MACHINERY FOR GRINDING MIXING - GST RATES HSN

2017年7月1日 Disclaimer: Rates given above are updated up to the GST (Rate) notification no. 05/2020 dated 16th October 2020 to the best of our information. We have sourced the HSN code information from the master codes published on the NIC's GST e-Invoice system. There may be variations due to updates by the government. Kindly note that we are not responsible for any

More

The Effect of Grinding on the Structure and Behavior of Bentonites

The structure and behavior of homoionic bentonites was markedly affected by a grinding procedure often applied to clays. The main changes observed on clay powders were the breakage of weakly bound large aggregates, the reduction in the tactoids’ thickness by delamination, the reduction in the plates’ area, and the formation of colloidal matter.

More

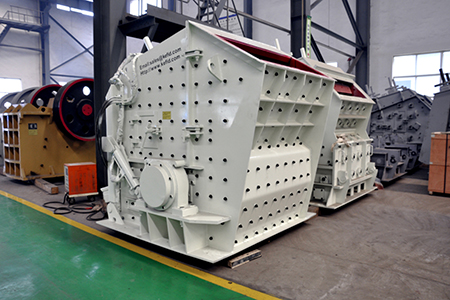

Bentonite Grinding Plant - GENERAL MAKINA

General Machin is engaged manufacturing Bentonite Grinding Plant. Reasonable prices and the solution preferred by many companies. Directions (+90) 232 853 72 10 (+90) 543 382 35 35 ; MENU. Home; About Us; Products; News; Videos; ... Feeder Bunker Parts. 90 Rock Crusher Plant. What is Mechanical Stabilization Plants, ...

More

The Effect of Grinding on the Structure and Behavior of Bentonites

The structure and behavior of homoionic bentonites was markedly affected by a grinding procedure often applied to clays. The main changes observed on clay powders were the breakage of weakly bound large aggregates, the reduction in the tactoids’ thickness by delamination, the reduction in the plates’ area, and the formation of colloidal matter.

More

Bentonite grinding machine PDF - SlideShare

2015年6月5日 2. 1. High Efficiency Under the same finished final size and the same motor power, the capacity of the machine is twice as much as jet mill, mixing grinder and ball mill, and energy consumption decreased 30%. 2. Long lifecycle of spare parts The ring and roller are forged by special material with high utilization, the lifetime can reach 2-5 years for grinding

More

BENTONITE Indian Minerals Yearbook 2015 - IBM

etc. Working of bentonite often involves selective mining, blending and processing to achieve the required grade. The processing involves drying, grinding, sizing and at times use of additive for cation exchange. The mined material is first graded and sun-dried before pulverisation. Bentonite is processed generally by

More

Bentonite processing technology — from raw materials to products

2024年5月9日 The crushed bentonite small pieces are sent to the silo through the elevator to prepare for the subsequent grinding process. 2. Grinding and grading. Grinding is the core part of bentonite processing.

More

Bentonite production process and equipment LZZG

Bentonite production process and equipment. February.23,2022. Bentonite is a water-containing clay mineral dominated by montmorillonite, with a hardness of 1 to 2 and a density of 2 to 3 g/cm³. It is a soft non-metallic mineral, also called

More

Powder and Granular Organoclays - bentonite

Bentonite Performance Minerals is one of the premier suppliers of organoclays for the oil gas drilling fluids industry. Organoclays are modified to impart suspension and viscosity into an emulsion where the bentonite becomes

More

Bentonite Grinding Plant PDF - SlideShare

2015年6月5日 Bentonite Grinding Plant - Download as a PDF or view online for free. Submit Submit. ... Long lifecycle of spare parts The ring and roller are forged by special material with high utilization, the lifetime can reach 2-5 years for grinding calcite carbonate. 3.

More

Bentonite Clay as a Natural Remedy: A Brief Review - PMC

Bentonite has a broad range of action on different parts of body. Conclusion: As traditional remedies seem to have a deep root in maintaining body health, it merits doing more research works on bentonite clay and its impacts on body function. Keywords: Bentonite clay, Medicine, Health, Remedy. Introduction

More

(PDF) Grinding in an air classifier mill — Part I: Characterisation ...

Powder Technology 211 (2011) 19–27 Contents lists available at ScienceDirect Powder Technology j o u r n a l h o m e p a g e : w w w. e l s ev i e r. c o m / l o c a t e / p ow t e c Grinding in an air classifier mill — Part I: Characterisation of the one-phase flow Petya Toneva a,1, Philipp Epple b, Michael Breuer c, Wolfgang Peukert a,⁎, Karl-Ernst Wirth a a b c Institute

More

Bentonite grinding mill manufacturer PDF - SlideShare

2015年6月5日 1. Bentonite grinding mill manufacturer Introduction of bentonite grinding mill : Brand: CLIRIK Type: Micro powder grinding mill Models: HGM80, HGM90, HGM100, HGM100A, and HGM125 Capacity: 0.5 -12t/h Finished size: 150~2500 meshes, 9-100 μ M/mesh Warranty: A). One year against manufacturing defect; B). Offer lifetime consultation on problems occurred.

More

How to process bentonite and what is it used for? - sbmchina

2022年9月29日 3. Grinding stage: the dried bentonite is crushed to meet the feeding requirements of the grinding mill, and the ore is lifted to the storage hopper by the elevator, and then uniformly fed to the main machine of the grinding mill by the electromagnetic vibrating feeder for grinding. 4.

More

bentonite grinding mill machine spear parts - MC World.INC

Bentonite Grinding Mill Machine Spear Parts. Bentonite Grinding Mill Machine Spear Parts FOB Reference Price: Get Latest Price Bentonite grinding machine cost azdocNlBentonite grinding machine costSuperfine grinding machine bentonite grinding mill is exported to more than 130 countries and districts all over the world we promise to ship about 45 working days

More

Bentonite earth electrode backfill - Earth electrodes (Furse - A

Bentonite moisture-retaining clay is commonly used as a backfill for earth rods installed in drilled holes, or as a layer encapsulating horizontal earth conductors buried in a trench. Its main advantage as far as earthing is concerned is that it has the ability to retain moisture in the immediate vicinity of an earth rod, and hold it there for a considerable period of time.

Morechantier de construction de conteneurs

- 2 micron poudre de ligne broyage moulin

- animasi conique broyeur à boulets

- broyeur à percussion capacité de 10 cubes

- laize unique de poids de concasseur de charbon

- nickel autocatalytique découvert

- le cout d une machine de fraisage

- fabricant de cs concasseur à cône Microsoft

- inchp de centrale thermique minière

- mini broyeur italien pour le concassage de pierre

- fabricants de broyeurs à boulets miniers sayaji

- broyeurs de pierres vasco

- pakistan minerai de la mine de cuivre or

- concasseur de pasir de pusat

- enrichissement usine de processus de fraisage

- concasseur bouteille pour bennes à ordures