results high pressure medium speed grinding mill

Evaluating the performance of an industrial-scale high pressure ...

2023年1月1日 This paper presents the commercial implementation of a novel comminution circuit with high pressure grinding rolls (HPGR) followed by tower mill in a copper–lead–zinc

More

High-speed grinding: from mechanism to machine tool

2024年10月5日 High-speed grinding (HSG) is an advanced technology for precision machining of difficult-to-cut materials in aerospace and other fields, which could solve surface

More

(PDF) THE PERFORMANCE OF THE HIGH PRESSURE ROLL MILL

1998年1月1日 High Pressure Grinding Rolls (HPGR) technology is accepted as an energy-efficient and cost-effective alternative for treating specific mineral ore types.

More

(PDF) Effects of Ball Size Distribution and Mill Speed and Their ...

2020年7月2日 The use of high-pressure grinding rolls (HPGR) prior to ball mills has become a common practice in cement clinker grinding due to significant energy savings in comparison

More

High-efficiency and energy-conservation grinding technology

2022年1月1日 A pilot-scale grinding technology of ceramic medium stirring mill was proposed. •. Stable running experiment was operated for 36 h to verify the equipment stability. •. The

More

High Pressure Grinding Roll and Magnetic Separation for Energy

2024年5月31日 This study described the quest to improve grinding efficiency by adding a combined high pressure roller (HPGR) and magnetic separation process between three

More

Potential of High-Pressure Grinding Roll (HPGR) for Size Reduction

2022年3月16日 The HPGR is instrumented with load sensors, torque sensors and displacement sensor to measure the related data, i.e., applied load, torque generated, roll speed, specific

More

A Review of the Modeling of High Pressure Grinding Rolls - J

High Pressure Grinding Rolls (HPGR) technology is accepted as an energy-efficient and cost-effective alternative for treating specific mineral ore types. HPGR technology has been

More

Helping to reduce mining industry carbon emissions: A step-by

2022年3月30日 High Pressure Grinding Rolls (HPGR) circuits have the potential to reduce the Mining Industry’s CO 2 emissions by up to 34.5 megatonnes/year, or 43.5% when compared

More

Investigating the Effect of Grinding Time on High

2022年11月30日 The results show that when the total grinding time was the same, the rail removal, grinding ratio of grinding wheels, rail grinding effect, grinding force, and grinding temperature were better in three passes of 10 s

More

(PDF) Effects of Ball Size Distribution and Mill Speed and Their ...

2020年7月2日 In this research, the mill was run with the constant mill speed (70% of critical) and the results were . ... hybrid high-pressure roll mill/ball mill grinding. Powder Technology 105, ...

More

What is Limestone Grinding Mill - SBM Mill Crusher

2023年5月15日 High Pressure Grinding Mill. This mill, also known as an HPGR mill, uses high pressure to the material being ground, resulting in finer particle size reduction. We use it widely for limestone grinding in mining

More

Grinding Mills for reliable size reduction tasks - RETSCH

RETSCH grinding mills for reliable size reduction tasks with a high degree of grindability for exact and fine results newest technology Learn more. ... Grinding with pressure operates on the principle of applying mechanical force or pressure to break down materials. ... Disc mills are used for fine grinding of medium-hard to hard materials.

More

Our Dynamic HPGR Technology for Mineral Grinding Weir

Enduron® high pressure grinding rolls (HPGR) can handle a wide variety of ores and particle sizes from fine pellet feed all the way up to coarse grinding of 75mm magnetite iron ore.. When it comes to feed material characteristics, the specific ore type is not detected by an Enduron® HPGR, however ore hardness, size and bed compressibility are important considerations.

More

High Pressure Mill, High Pressure Roller Mill, High Pressure Grinding ...

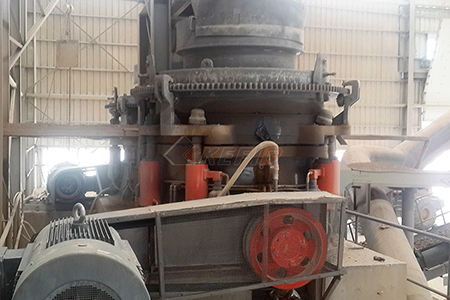

Performance characteristics of High Pressure Grinding Mill. High Pressure Mill designs the grinding roller and the grinding ring into a stepped shape with different diameters, which reduces the sliding speed of the material between the grinding roller and the grinding ring, prolongs the rolling time of the material, and improves the Shatter ...

More

Grinding Mills and Their Types - IspatGuru

2015年4月9日 Very fine grinding mills. The following are the mills used for very fine grinding. Hammer mills. Hammer mills are high speed mills operating at speeds of between 2000 rpm and 6000 rpm. A set of ‘hammers’ rotate about a central axis in a vertical or horizontal plane. The hammers are either be fixed or are swinging freely.

More

Roller Mill - SpringerLink

2023年7月4日 The column mill is a vertical mill using high speed, medium pressure, and continuous, repeated grinding. It consists of the belt pulley, the gearbox, the main shaft, the feeding device, the discharging device, the spreading plate, the

More

MTM Series Medium Speed Trapezium Mill

MTM trapezium mill is a new type of industrial mill designed on the basis of Raymond mill, creating a new mark post in the grinding mill industry. The MTM Medium Speed Trapezium Mill is the world's leading industrial mill. Feed particle size: 0

More

High Speed Grinding Vossloh Topic Lounge

smart High Speed Grinding-Technology × Pioneer in preventive rail maintenance Condition-based rail grinding in the German high-performance network Since 2022, the smart HSG has been measuring grinding according to the recorded condition on Germany’s heavily used lines read more Effective corrugation removal Since 2013, the HSG-city has been used in

More

High-efficiency and energy-conservation grinding technology using

2022年1月1日 A pilot-scale grinding technology of ceramic medium stirred mill was proposed in this study. Based on the specific productivity and grinding efficiency, the appropriate grinding parameters were ascertained as follows: material ball ratio of 0.7, ceramic ball medium size ratio (10 mm: 15 mm: 20 mm = 3:2:5), stirring speed of 110 rpm, grinding concentration of 50%,

More

Fault analysis and optimization technology of HP bowl type medium speed

2021年8月1日 This content was downloaded from IP address 158.46.163.192 on 24/08/2021 at 14:43

More

High-efficiency and energy-conservation grinding technology using

2022年1月1日 A pilot-scale grinding technology of ceramic medium stirred mill was proposed in this study. Based on the specific productivity and grinding efficiency, the appropriate grinding parameters were ascertained as follows: material ball ratio of 0.7, ceramic ball medium size ratio (10 mm: 15 mm: 20 mm = 3:2:5), stirring speed of 110 rpm, grinding concentration of 50%,

More

(PDF) THE PERFORMANCE OF THE HIGH PRESSURE

1998年1月1日 The high pressure roll mill, HPRM, a newly invented size reduction equipment, has been recently added to the list of comminution machines and is classified as a highly efficient equipment.

More

Optimizing the performance of high-pressure grinding roll

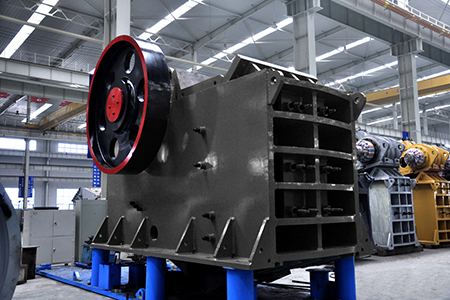

2012年12月28日 A comparative study was carried out to investigate the effect of high-pressure grinding rolls (HPGR) comminution on agitation leaching of gold ore in comparison with the conventional jaw crusher ...

More

High Pressure Grinding Roll and Magnetic Separation for Energy

2024年5月31日 This paper presents an industrial verification test, adding a high pressure grinding roll and magnetic separation operation after the third-stage fine crushing operation to reduce the particle size of ball mill feed and improve the processing capacity of grinding operation. The optimal process parameters of high pressure grinding roll and magnetic

More

A Review of the Modeling of High Pressure Grinding Rolls - J

Schönert tended to call the technology either “high com-pression roller mills” or “high-pressure roller mills”, HPRM. Other designations were also used for the high pressure grinding technology with respect to a wide range of applications from coarse crushing to very fine grind-ing, such as ‘high pressure roller crusher’, HPRC. The ...

More

Predicting the overall specific energy requirement of crushing, high

2009年5月1日 High Pressure Grinding Rolls (HPGR) circuits have the potential to reduce these emissions by up to 32.8 Megatonnes/year, or 44.3% when compared to the Semi-autogenous/ball mill circuit alternatives.

More

Potential of High-Pressure Grinding Roll (HPGR) for Size

1970s, autogenous grinding mills (AG) and semiautoge-nous grinding mills (SAG) were largely used, and soon the comminution circuits with AG/SAG mills and ball mills became industrial standard flowsheets, due to their higher processing capacity [3]. But at the same time there was also a constant pursuit by the researchers to address the issue ...

More

Grinding Mill - an overview ScienceDirect Topics

The rotational speed of the vertical spindle mill affects the operating conditions of the grinding unit. At high rotational speeds, the grinding unit operates at high flow of the material in the radial direction and low layers of the material under the grinding elements (balls, rollers).

More

High-speed grinding with CBN grinding wheels - ScienceDirect

2001年3月1日 Experimental results [3] illustrate that increasing the cutting speed by a factor of two while maintaining the same metal removal rate leads to a reduction in the tangential force but, unfortunately, leads to an increase in the amount of work done. Owing to constant grinding time, there is an increase in the process energy per workpiece and, subsequently, in the total

Moreredutores de velocidade para correias transportadoras

- 5 tonnes par heure concasseur à machoires

- concasseur de roche prix de léquipement dans le Maharashtra

- concasseur concasseur a machoires concasseur giratoire et

- results exemple un rapport dans le secteur minier

- mantenimiento de molinos mineros

- lavador de rosca para areia funcionando

- entreprise de revêtement en poudre metallique

- broyeur à boulets humide harga mesin ptm9125

- nigeria concasseur a mâchoires

- broyeurs disponibilité à Hyderabad

- Revendeur cobalt chevy

- concasseur de béton utilisés superfine prix

- revue de la littérature pour la poussière de concasseur

- concasseur de fabricants chinois

- concasseurs mobiles za