cone crusher optimization

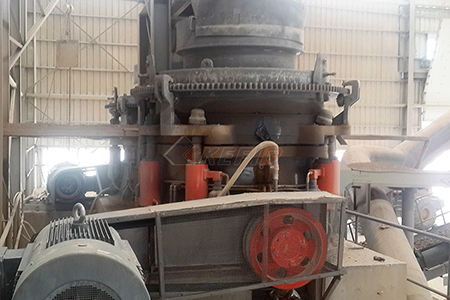

Chamber Optimization for Comprehensive Improvement of Cone

2021年3月15日 This study aims to analyze the impact of key structural parameters such as

More

A review of modeling and control strategies for cone crushers in

2021年8月15日 The most important research topics are (i) mass balance control of crushing

More

New developments in cone crusher performance optimization

2009年6月1日 This physics based virtual comminution model will enable engineers to

More

Constant Wear Criterion for Optimization of the

2022年6月24日 Based on the constant wear criterion, cone crushers can be optimized to obtain a crushing chamber with constant wear characteristics, which provides theoretical support for the development of new high-efficiency cone

More

On-line optimization of cone crushers using Extremum-Seeking

2013年8月30日 Abstract: This article demonstrates the ability of on-line optimization of cone

More

Influence of Two Mass Variables on Inertia Cone

2021年2月4日 In the inertia cone crusher design, an inevitable problem concerns how to determine the two mass variables (fixed cone mass and moving cone mass), which can affect the crusher dynamic performances. Firstly, the

More

Review of Working Performance Modeling and Optimization of

Improving working performance of cone crusher contributes to developing cone crusher of

More

Analysis and optimization of cone crusher performance

2009年10月1日 To optimize the crushing chamber of the gyratory crusher, the discrete

More

Analysis and optimization of cone crusher performance

2009年10月1日 Request PDF Analysis and optimization of cone crusher performance Solving practical problems in cone crusher design, the quantity of rock material falling out of the crushing chamber during ...

More

Chamber Optimization for Comprehensive

2021年3月15日 Another chamber optimization was performed by adopting a dual-objective optimization of productivity and product quality in a C900 cone crusher [22]. The productivity was determined with an ...

More

Real-Time Optimization of Cone Crushers - Semantic Scholar

Cone crushers are used in the mineral, mining, and aggregate industry for fragmentation and production of rock materials. Cone crusher control systems are widely used for machine protection, wear compensation and, to some extent, increasing production. These systems ordinarily focus on the crusher and not the yield of production process. In this thesis real-time

More

(PDF) Influence of Two Mass Variables on Inertia Cone Crusher ...

2021年2月4日 The fixed cone mass and moving cone mass of a balancing crusher are decreased by 78.9% and 22.8%, respectively, compared to without the balancing mechanism. Simulation parameters for MBD-DEM.

More

(PDF) Cone Crusher Performance - ResearchGate

2015年5月13日 In this thesis a method for prediction of cone crusher performance is presented. ... By applying suitable optimization methods it would be possible to obtain the optimal.

More

Constant Wear Criterion for Optimization of the Crushing

2022年6月24日 Cone crushers are high-efficiency particle crushing instruments utilized in a variety of industries [].The crushing chamber is one of the core components of a cone crusher [], and is directly related to the performance of the cone crusher and the quality of the crushed products.Meanwhile, changes in the crushing chamber caused by wear can significantly

More

Review of Working Performance Modeling and Optimization of Cone Crusher

Improving working performance of cone crusher contributes to developing cone crusher of new style, high efficiency, energy saving and environment protection. In the past few decades, a large number of research results were obtained in the performance optimization of cone crushers.

More

New developments in cone crusher performance optimization

Minerals, 2021. This paper reports the calibration and validation of a cone crusher model using industrial data. Usually, there are three calibration parameters in the condensed breakage function; by contrast, in this work, every entry of the lower triangular breakage function matrix is considered a calibration parameter.

More

Review of Working Performance Modeling and Optimization of Cone Crusher

2011年8月1日 Key design parameters (oscillating speed, closed size setting, base angle of cone, eccentric angle) which affect cone crusher performance were studied for the cone crusher performance optimization.

More

[PDF] Influence of Two Mass Variables on Inertia Cone Crusher ...

2021年2月4日 DOI: 10.3390/MIN11020163 Corpus ID: 234049252; Influence of Two Mass Variables on Inertia Cone Crusher Performance and Optimization of Dynamic Balance @article{Cheng2021InfluenceOT, title={Influence of Two Mass Variables on Inertia Cone Crusher Performance and Optimization of Dynamic Balance}, author={Jiayuan Cheng and

More

Webinar: Maximizing cone crusher efficiency using

Thank you for your interest in "Maximizing cone crusher efficiency using chamber optimization" webinar! Please view the recording to the left by pressing play. If you are experiencing difficulties, you can also access the webinar

More

Cone crusher chamber optimization using multiple constraints

2009年10月1日 Request PDF Cone crusher chamber optimization using multiple constraints The chamber geometry is one of the key factors that influences the performance of a cone crusher. The design of the ...

More

Chamber Optimization for Comprehensive Improvement of Cone Crusher ...

-e r e parameters of e cone r e e y parameters that t e e of e crusher.-ebottomeofemantle α,elengthofe parallelzonel,ece c,derotatingd n edeterminedasedesignsofedual-objective gmodel,asnineg: X x 1,x 2,x 3,x 4 [n,c,α,l]. (12)-eeeofecrushingoptimizations s t by g to e parameters of e C900 cone crusher.-eparametersofC900eninTable2e

More

New developments in cone crusher performance optimization

Minerals, 2021. This paper reports the calibration and validation of a cone crusher model using industrial data. Usually, there are three calibration parameters in the condensed breakage function; by contrast, in this work, every entry of the lower triangular breakage function matrix is considered a calibration parameter.

More

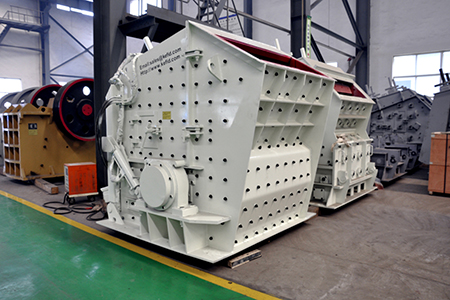

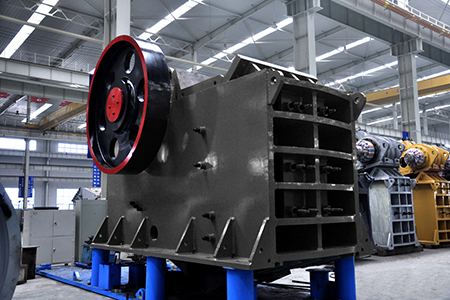

(a) Structure diagram and (b) functional principle diagram of cone crusher.

The mathematical modeling and optimization of the parameters and working processes of a cone crusher were addressed in [22, 23].A mathematical model of the working process of a jaw crusher was ...

More

Multi-Objective Optimal Control Method for the 6-DOF Robotic Crusher

2024年10月15日 Lyu, N. Construction of Discrete Element Model and Optimization Design of Key Parameters of Cone Crusher. Master’s Thesis, Huaqiao University, Quanzhou, China, 2020. [Google Scholar] Peng, S. Preparation Techniques and Wear Mechanism of Light-Weight Wear Resistant Steel for Cone Crusher Lining Plate.

More

Simulation and optimization of gyratory crusher performance

DOI: 10.1016/j.powtec.2020.07.034 Corpus ID: 224851552; Simulation and optimization of gyratory crusher performance based on the discrete element method @article{Chen2020SimulationAO, title={Simulation and optimization of gyratory crusher performance based on the discrete element method}, author={Zeren Chen and Guoqiang

More

Cone crusher chamber optimization using multiple constraints

2009年10月1日 A new model extension considering the interparticle shape for vertical shaft impact crushers was developed in Bengtsson and Evertsson (2006b). Gang et al. (2009b,a) proposed a heuristic model of cone crusher throughput and product flakiness based on the crushing chamber geometry, rotational speed, material harness, and bulk density of the final

More

Review of Working Performance Modeling and Optimization of Cone Crusher

2011年8月1日 Key design parameters (oscillating speed, closed size setting, base angle of cone, eccentric angle) which affect cone crusher performance were studied for the cone crusher performance optimization.

More

Cone crusher optimization – what you need to know

To optimize your cone crusher, there are many factors you need to consider. In this webinar, John Starck takes a back to basics approach for what factors you should look at and shares tips and tricks on optimizing your cone crusher without compromising reliability.

Morebroyeur de pierres jamaica

- broyeurs a marteaux a vendre aux philippines

- fabricante brasileiro de moinho para fábrica de cimento

- faire vibrer grace a un moteur

- broyeur de debris shanghai

- canada exploitation miniere de minerai

- concasseur statique usine

- matériau utilisé pour uxite

- Contoh presentasi sebagai ventes prodak

- l'utilisation de microbes dans l'extraction de minerais

- concasseurs à mâchoire SKD fabricants de malaisie

- équipement de broyage italie

- machine a plaques de platre de ponage allemagne

- Machine angleterre pour broyeur d or

- inclinant prix de meuleuse en ligne

- laveuse de sable biotite