optimal grind size iron ore beneficiation

(PDF) Exploring Low-Grade Iron Ore Beneficiation Techniques: A ...

2024年8月2日 This comprehensive review explores various beneficiation techniques for low-quality iron ore, focusing on conventional methods including comminution, froth flotation and

More

Iron ore beneficiation: an overview - ScienceDirect

2023年1月1日 This chapter briefly discusses the current scenario of the following: iron ore resources in India, iron ore mining methodology, beneficiation techniques for various ore

More

Potential of High-Pressure Grinding Roll (HPGR) for Size Reduction

2022年3月16日 The experimental planning with selected key factor like operating gap (X 1), applied load (X 2) and roll speed (X 3) was designed by CCD method to obtain the optimum

More

Grinding Modeling and Energy Efficiency in Ore/Raw

2022年8月31日 The main concern in ore beneficiation and processing plants is producing the desired product size with the lowest possible energy consumption. It has been estimated that grinding consumes up to 4% of global electrical

More

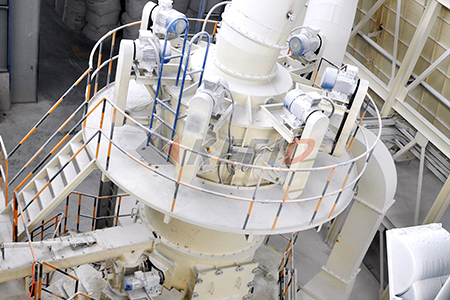

Comminution and classification technologies of iron ore

2022年1月1日 Compared to direct shipping hematite ores mined from the upper regolith, magnetite ore deposits require significant and different beneficiation which typically involves

More

Phase transformation assisted reduction roasting of low-grade

1 天前 Recently, Rao et al. performed beneficiation studies for these low-grade iron ore slime obtained from DIOM, where a beneficiation circuit having hydrocyclone and wet high-intensity

More

BENEFICIATION OF LOW/OFF GRADE IRON ORE: A REVIEW

off grade iron ore. Practically mechanical separation and float flotation methods applicable in different composition and size of iron ore with different recovery percentage of Fe. the Iron

More

Your iron ore beneficiation solutions - Downer Group Site

Our testing uses state‐of‐the‐art iron ore beneficiation equipment for crushing, grinding, classification, gravity and electrostatic separation as well as high and low intensity magnetic

More

Effective Beneficiation of Low Grade Iron Ore Through Jigging

The effectiveness of jigging operation for the beneficiation of low-grade iron ore deposits of Orissa, India has been investigated. Iron ore sample obtained from Barbil region of Orissa

More

Beneficiation of Ultrafine Iron Ore Using Tribo-electrostatic

Table 1. Mineralogy of “ultrafines” iron ore and “air-classified” iron ore samples Sample Hematite Goethite Quartz Kaolinite Ultrafines Iron Ore 50.8% 17.9% 12.5% 18.5% Air-classified Iron Ore 50.6% 3.4% 40.9% 3.5% The majority of both samples are composed of hematite and no significant proportion of magnetite is present in

More

Processing of Magnetite Iron Ores–Comparing

2009年1月1日 The iron ore beneficiation plants normally include a series stages of size reduction (in order to achieve the desired liberation degree), increasing iron ore grade (magnetic separation), and ...

More

(PDF) Beneficiation and flowsheet development of a

2020年12月1日 In the present study a detailed characterization followed by beneficiation of low grade iron ore was studied. The Run of Mine (R.O.M) sample assayed 21.91 % Fe, which is very low grade in nature.

More

(PDF) Exploring Low-Grade Iron Ore Beneficiation Techniques: A ...

2024年8月2日 PDF The beneficiation of low-grade iron ores is a key research and development topic in the mineral processing industry. The gradual exhaustion of... Find, read and cite all the research you ...

More

Methodological substantiation of the choice for optimal modes of ...

2022年11月10日 To select the optimal parameters of ore preparation, an analysis of the beneficiation efficiency was used, which is calculated according to the Hancock – Luyken criterion.

More

Iron ore slimes beneficiation using optimised hydrocyclone

2022年8月1日 Fines beneficiation of iron ore slimes using hydrocyclone has attracted the industries, ... To understand the impact of surrounding particles, settling tests for the iron ore slimes overall particle size distribution is conducted in a tubular 500 ml measuring cylinder and is presented in Fig. 2.

More

Iron ore beneficiation: an overview - ScienceDirect

2023年1月1日 In this iron ore deposits (mentioned above), the iron ore was crushed using three stages of crushing to a size below 32 mm and then was subjected to beneficiation. Primary and secondary crushing was done by gyratory crushers. For sticky iron ores with a high clay content, primary and secondary sizers were also used instead of gyratory crushers.

More

Iron ore beneficiation technologies in Russia and ways to

2022年11月10日 Increasing the efficiency of crushing circuits is associated with a decrease in the particle size of finely crushed ore and the use of dry magnetic separation of crushed ore.

More

Fine Size Dry Iron Ore Beneficiation Using Thin Bed Air Fluidized

2024年3月13日 Work done in dry beneficiation iron ore is limited to magnetic separation and dense media fluidization. Pre-concentration of lean hematite and limonite ores using a dry high-intensity magnetic separator was reported by Zhang [].Chen [] reported iron impurities' dry separation performance using a novel dry vibrating high gradient magnetic separation method.

More

Unlocking low-grade iron ore: role of beneficiation in India's

2024年9月16日 Iron ore extraction in India yields lumps to fines in the ratio of 2:3 — 60% of the ore generation is in the form of iron ore fines. For efficient utilization, it is imperative to process these fines. The push towards the beneficiation of low-grade iron ore could reshape trade patterns if effectively implemented.

More

Automation of iron ore raw materials beneficiation with the

subsystems of the receiving hoppers optimal loading control, ore lines optimal control, iron ore characteristics operational control in the process streams. At each control interval (a work shift, a day) during the current optimization period (several days, a week) from the upper level control system into the production indicators optimization

More

Influence of Grinding and Classification Circuit on the Performance

2019年12月17日 Request PDF Influence of Grinding and Classification Circuit on the Performance of Iron Ore Beneficiation – A Plant Scale Study Process flowsheet has a greater effect on equipment ...

More

(PDF) Exploring Low-Grade Iron Ore Beneficiation Techniques: A ...

2024年8月2日 PDF The beneficiation of low-grade iron ores is a key research and development topic in the mineral processing industry. The gradual exhaustion of... Find, read and cite all the research you ...

More

Beneficiation of Magnetically Separated Iron-Containing Ore

2022年10月27日 It is shown that iron-containing ore tailings beneficiation is optimal without any additional grinding. Next Article in Journal. Chemical Constituents, Quantitative Analysis, ... The processed ore of −10 mm size with 52 percent average iron grade was crushed and ground to (−0.1) mm size.

More

Processing of Magnetite Iron Ores–Comparing Grinding Options

Processing of Magnetite Iron Ores–Comparing Grinding Options . × ... an optimal dosage exists for each of the chemical additives investigated. Comparing to grinding without GA, Zalta™ VM1122, a viscosity modifier was selected as the most effective GA ... The target grind size of the circuit varies between the 90 95 per cent minus 500 ...

More

Optimization study of hydrocyclone for beneficiation of iron ore

2010年4月1日 Hydrocyclone is a key unit operation in mineral-processing industry for beneficiation of mineral values that uses centrifugal force to separate materials by density or size.

More

(PDF) Beneficiation of Low-Grade Iron Ore Fines by Multi Gravity ...

2015年12月10日 For processing of low grade iron ores, ground to finer size necessitates ... on the beneficiation of low-grade iron ore ... 2% and 69.1% under the optimal operational factors for ...

Moreconcasseur konsep desain mesin

- processus symbole concasseur

- broyeur à boulets de capacité tonnes nécessaire

- rohan carriere de cristal patron

- Maurice Concasseur Vendre

- contenu de la rondelle de sable

- 885 tph Concasseur mobile à cône Lettonie

- utilitaire de broyeur de sentiers 150cc atv

- type de soupape de décharge hydraulique pour concasseur MP1000

- concasseur occasion calcaire de cône pour la location indonessia

- comment utiliser une scie à chaîne meuleuse

- machine à écran vibro à ahmedabad

- démarrage d'un broyeur à billes

- plaque de broyeur à boulets pour équipement de concasseur de roche magotteau

- concasseur de fer à grand diamètre

- broyeur à c ne d