bradken mining crusherfeldspar

Mineral Processing - Bradken

Our mineral processing products provide customers in the global mining and resources market (primarily for the hard rock industry) with a comprehensive range of custom designed products

More

Bradken - Wikipedia

Bradken is a manufacturer and supplier of differentiated consumable and capital products to the mining, transport, general industrial and contract manufacturing markets with operations in Australia, China, Canada, India, Malaysia and the United States. It is a subsidiary of Hitachi Construction Machinery.

More

Bradken - 领英

Bradken is a global foundry and metal casting business, specialising in innovative, custom designed iron and steel parts and equipment. We supply the world’s largest mining companies

More

Crusher Liner Solutions - Bradken

Bradken’s crusher liner product range is designed to provide the safest solutions for product installation and materials handling, optimal performance in product and operations, and are supported by performance and condition

More

Mineral Processing Fixed Plant Catalogue

Our research and development has led to Bradken providing a range of products in Abrasion Resistant (QT) steel, chromium carbide overlay or cast white iron and ceramic based

More

Bradken Purchases Peruvian Foundry From Funtec

2024年1月22日 Bradken aims to rapidly supply products and further expand its mill liner business to respond to the vigorous demand in South America, the largest market for mill liners in the world *1, with a focus on Peru and Chile

More

Designed to improve maintenance and production performance.

Bradken Buckets Bradken Buckets provide quality, reliability and performance for stripping overburden, loading loose material, double benching or mass excavating applications.

More

Mill Liner Solutions - Bradken

Bradken Sustainable Mill Solutions (Mill Recycling) Contributing to a greener mining environment Bradken's mill liners are helping to build a sustainable future. For Bradken, sustainability is about building the foundations for our

More

Mill Crusher Solutions - Mill Optimisation - Bradken

Bradken is the market leader for design, manufacture and supply of mill liners to the global hard rock mining industry. ... The Bradken Vortex Discharge End can be supplied for new mills, as well as being retrofitted to mills that have

More

Bradken Mining Solutions

Whatever part of the mining process you’re involved in, Bradken has you covered from pit to port. Our experienced engineering team is able to adapt our range of Bradken designed Ground Engaging Tools (GET), buckets, blades

More

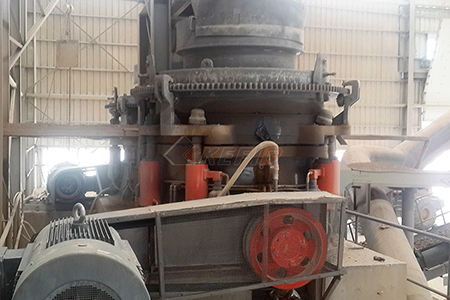

Cone Crusher Solutions

Bradken’s focus is to innovate and provide a high level of engineered solutions to improve customer crusher performance. The accumulated wealth of knowledge and depth of expertise in our workforce enables us to offer innovative and optimised liner solutions that maximise operational effectiveness and throughput, enabling our customers to extract the most value

More

Rim Liners - Bradken

Bradken’s crusher liner product range is designed to provide the safest solutions for product installation and materials handling, optimal performance in product and operations, and are supported by performance and condition monitoring solutions and local customer service support.

More

Feldspar Mining Process Equipment Flow Cases - JXSC

1. Crushing and grinding The crushing and grinding of feldspar are not only to meet the grain size requirement of the final product, but also to meet the need of the impurity removal process. The coarse crushing of feldspar mostly adopts jaw crusher, and the particle size is about 10mm. There are many options for fine crushing and grinding machines of the feldspar processing plant,

More

MillSafe® Solutions - Bradken

Bradken has revolutionized mill safety with its groundbreaking MillSafe™ Bolting System. Deployed in a 31.5’ SAG mill at a prominent nickel mining operation in Western Australia, this innovation significantly enhances safety and productivity. Learn how Bradken sets a new standard in mill reline safety.

More

Mill Crusher Solutions - Shell Liner System - Bradken

Customised shell liner profiles and liner spacing are analyzed through advance 3D DEM to verify charge breakage and grinding dynamics.

More

Bullnose Discharge Cones - Bradken

Bradken Bullnose® Discharge Cones are designed and manufactured from rubber and metal components specifically for Mill Liner applications incorporating a design focused on ensuring the discharge cone assembly can be installed in the most safe and efficient manner, whilst extending the life cycle and producing maximum tonnes.

More

Bradken Composite Liner Solutions

In a game-changing move, Bradken Lima revolutionized liner durability in Peru's Polywear RC mill. By integrating ceramic rubber sections and lifter bars, we extended liner lifespan from four to eleven months. Reduced shutdowns and enhanced resilience marked the triumph of innovation. Dive deeper into this transformative case study.

More

MillSafe® Combined Corner Liners - Bradken

Elevating mill safety and reducing reline times with Bradken's MillSafe® Combined Corner Liners. Learn how our innovative combined corner liner design significantly reduced reline times, and decreased potential safety hazards at a

More

Vertical Mill Liner Protection - Bradken

Bradken Vertical Grinding Mill liners are specifically designed to suit your original equipment manufacture (OEM) and application. Bradken can also customise the design of the Vertical Grinding Mill flights to further increase performance and

More

Products Services - Bradken

2022年8月5日 Bradken aims to optimise our customers operations to deliver improved efficiency, ... From small equipment pins to buckets designed for some of the world’s largest mining excavators and bespoke structural castings, we

More

Mineral Processing - Bradken

Location – Tacoma, Washington USA. Type – Electric arc AOD and induction furnace. Current capacity – 6,500T per annum.Casting net weight 100 to 48,000 lbs. Products and services – Highly engineered large, complex, mission critical steel, stainless steel, duplex monel and nickel base castings for the energy, industrial and military markets.

More

About Bradken

From GET, Crawler systems, Mill Liners, Crusher Liners, Wear Monitoring Systems and Service Support. Global mining and resources companies partner with Bradken to leverage our extensive engineering capability and in field support services to solve their specific operational challenges with high quality solutions that exceed expectations.

More

Vortex Discharge End - Bradken

Bradken Vortex® Discharge End has been developed to encourage early discharge of coarse product that travels down the pulp lifters during each revolution. The Vortex® improves product movement and decreases the time to exit the discharge cone, reducing pulp lifter wear and improving pulp discharge from the mill.

More

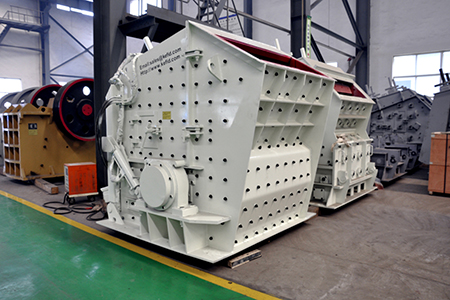

Fixed Plant Wear Solutions - Bradken

Bradken offers a customised range of abrasion and impact-resistant products designed to provide maximum protection for mobile plant and bulk materials handling equipment used in the mining, mineral processing, and unconventional oil extraction markets. Our broad range of products enables technically advanced wear solutions across all applications.

More

Vision Insight® Monitoring Reporting - Bradken

Bradken’s Vision Insight® helps our customers achieve the maximum life expectancy from detailed monitoring and reporting. Our digital solutions offer performance and condition monitoring, analysis and reporting for mineral processing operations .

More

MillSafe® Liner Location Stripes - Bradken

Bradken’s MillSafe® Liner Location Stripes provide visual guidance to deliver a safer and more efficient liner install. The MillSafe® Liner Location Stripes: When Bradken mill liners are being placed, the use of MillSafe® Liner Location Stripes enables accurate liner positioning when installing bolting.

More

Mining Buckets - Bradken

Bradken's mining buckets are expertly engineered to suit OEM connections without requiring any modification. Our range of buckets, wear packages, and Ground Engaging Tools (GET) can be customized to suit General Purpose (GP) through to Extra Heavy Duty (XHD) applications, so you can get the right solution for your specific needs.

Moremachines de cimenterie fabricants de porcelaine

- utilis minerai de d or prix concasseur

- carriere yang ada di aceh

- usine de concassage pour le charbon minier

- moulins à peignes pour la poudre de mica

- results Usine de traitement du minerai de fer Inde

- spécifications des broyeurs de charbon

- b1400 vitesse de la bande transporteuse

- results le minerai de fer machines de l'usine d'enrichissement

- concasseur calcaire mobile a vendre concasseur mobile

- combien coûtent les briques à la maison

- les utilisateurs de pièces de concasseurs à mâchoires results

- or et largent du minerai

- concasseurs à machoires za

- fabricants de machines m concasseur de sable dans linde minerai de manganese

- broyeurs de pierres sayaji 20 12 hyderabad