cement grinding distributor

Concrete Floor Grinders - Superabrasive

Concrete Floor grinders are used to prepare, level, polish, remove glues and coatings on concrete or other hard floors. Lavina planetary grinders are durable, easy to use and maintain, and they outperform other machines, because they

More

Cement Grinding Suppliers, Manufacturer, Distributor, Factories,

Alibaba offers 828 Cement Grinding Suppliers, and Cement Grinding Manufacturers, Distributors, Factories, Companies. There are 475 OEM, 441 ODM, 131 Self Patent. Find high

More

Lavina Concrete Grinders - Official Dealer - Niagara Machine

We are a top distributor of Superabrasive's many popular concrete surface preparation brands, including Lavina grinders, Lavina dust collectors, and their new power trowels. Lavina

More

Polished Concrete Solutions - Surface Prep Concrete

PCS specializes in surface prep and concrete polishing products including concrete grinders and polishers, grinding segments, polishing pads, polishing dyes, concrete densifier, and general concrete tools and supplies.

More

CEMENGAL. Engineering, equipment and assembly for

25 years in the cement industry supplying engineering and equipment for assembly and commissioning of clinker and slag Grinding Station, cement plants, metallic and concrete silos, vertical mills, horizontal mills,

More

Schwamborn home Floor grinders, concrete screed

Concrete grinders, floor milling machines, smoothing cleaning machines, industrial vacuum cleaners - for surface preparation, renovation, design and maintenance of industrial flooring, concrete, screed, natural stone flooring,

More

Wholesale Concrete Grinding Tools Manufacturers Suppliers

Wholesale Concrete Grinding Tools manufacturers suppliers found with 3,285 products. Product List. Supplier List. Secured Trading Service.

More

Construction Equipment For Sale Scarifiers, Grinders

EDCO’s Magna-Trap® Concrete Floor Grinders are used for topical applications up to 1/16” deep. Smooth, clean, remove thin coats, and prep surfaces! Shop Now. Turbo Grinders. EDCO’s high speed Turbo Grinders are designed for

More

Cement Grinding Aids - Liquid Grinding Aid

Distributor / Channel Partner of Cement Grinding Aids - Liquid Grinding Aid offered by Nakoda Enterprises, Indore, Madhya Pradesh. Send Email 07942549275 79% Response Rate

More

Albarq Cement Industry LLC – Leading manufacturer

We are the leading supplier of Portland cement in Abu Dhabi. Our cement grinding unit capacity is 400,000 tons/year. We focus on Quality! Our Products. Ordinary Portland cement (OPC) 42.5N as per BSEN 197-1:2011 and ASTM

More

Cement Grinding Aid / Strength Improver Aid - Nexco

NEXCEM-series are organic chemical cement grinding aids to optimize particle size and prevent re-agglomeration. It is eliminating the materials which interrupts the cement hydration. Thus NEXCEM improves productivity and increases

More

SikaGrind®-455 GNT Cement Grinding Aids Sika Canada

The dosage rate of SikaGrind®-455 GNT will depend on desired characteristics of each type of cement. Dosage rates typically range from 0.02 % to 0.08 % by weight of cement for Types GU MS cements and from 0.03 % to 0.09 % by weight of cement for Type HE cements. The optimum dosage rate should be determined during full-scale cement mill tests.

More

Cement in West Africa

2018年10月1日 Liberia has one cement grinding plant, which is located in the capital Monrovia. It is operated by Cemenco, an 81.67% HeidelbergCement subsidiary. The 0.8Mt/yr plant has been in operation since 1968. It produces Portland cement in 50kg bags and distributes them via a network of 30 distributors.

More

Asia Cement

Asia Cement Trading Company LLC (ACTC) is professionally dynamic and one of the premier trading companies in entire UAE in supplying high quality Cement, Armor Rock, Gravel Sand, Aggregate and serving the construction industry since 1998.

More

Cement Supplier in the UAE - Rashidco Cement, Abu Dhabi

Rashidco Cement Est. is a leading cement supplier in the UAE. Our premium cement products have earned the trust of cement companies across UAE. UAE's No.1 Trusted Cement Brand. All Over UAE +971-2-6742375; info@rashidcocement; Home; About; Services; Our Products; #KNOWYOURCEMENT Open menu.

More

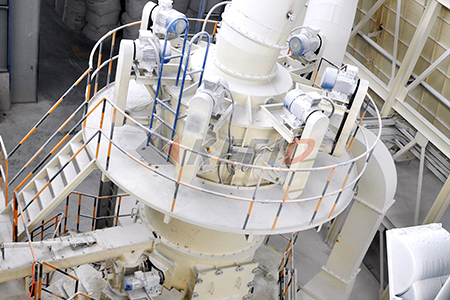

Cement Grinding - Cement Plant Optimization

Grinding aids also serve to reduce coating problems in cement storage and enhances cement strengths. GRINDING MILLS. Mills will be selected according to type most suitable for required capacity and duty and for overall power consumption. Cement grinding operation may be performed in one of the following mill setups. Ball and tube mills.

More

Home - Welcome to Dangote Cement Plc

Absence of limestone in much of West Africa and Central, especially coastal states, has led some of those countries to import bulk cement or its intermediate product, clinker, usually from outside of the African Continent. Our vision is for West and Central Africa to become cement and clinker self-sufficient, with Nigeria being the main export hub.

More

CEMENT GRINDING COURSE - The Cement Institute

The purpose of the training is to Identify and understands necessary known and unknown information towards the completed cycle of the grinding system, whether is a ball or vertical mill. Throughout the course the lectures are

More

Surya Gold Cement - Preferred Brand of North East India

Cement production is a lengthy process that begins with the extraction and grinding of raw materials such as limestone, clay, and marl into a fine powder known as raw meal, which is then heated to a sintering temperature of up to

More

Cement Grinding - Cement Plant Optimization

Grinding aids also serve to reduce coating problems in cement storage and enhances cement strengths. GRINDING MILLS. Mills will be selected according to type most suitable for required capacity and duty and for overall power consumption. Cement grinding operation may be performed in one of the following mill setups. Ball and tube mills.

More

Ceramic vs. Steel Grinding Balls: A Comprehensive Comparison for ...

2024年2月22日 In cement manufacturing, steel balls are used in large quantities for the grinding of clinker into fine powder, where their durability and cost-effectiveness are highly valued. Conclusion. In comparing ceramic and steel grinding balls, each material exhibits distinct advantages tailored to specific industrial needs.

More

CEMENT GRINDING SYSTEMS - INFINITY FOR CEMENT EQUIPMENT

The final manufacturing stage at a cement plant is the grinding of cement clinker from the kiln, mixed with 4-5% gypsum and possible additives, into the final product, cement . In a modern cement plant the total consumption of electrical energy is about 100 kWh/t . The cement grinding process accounts for approx. 40% if this energy consumption.

More

The growing cement industry of the UAE

2015年2月9日 Star Cement is a wholly-owned subsidiary of UltraTech Cement, part of India's Aditya Birla Group. Star Cement operates one 2.4Mt/yr integrated cement plant in Ras al-Khaimah, one 1.2Mt/yr cement grinding plant in Abu Dhabi and one 900,000t/yr cement grinding plant in Ajman. Star Cement owns the largest number of cement plants in the UAE.

More

WerkMaster: Buy Concrete Floor Grinding Equipment Online

Increased Labor Savings: By eliminating the need for separate edging machines, contractors can streamline their workflow and reduce labor costs. Dual Power Options: WerkMaster streamlines the power sourcing process for contractors, allowing them to focus on the job itself. Best in Class Performance: WerkMaster's proprietary system that utilizes multiple fixed discs with individual

More

Cement Grinding Aids - Liquid Grinding Aid Distributor /

Distributor / Channel Partner of Cement Grinding Aids - Liquid Grinding Aid offered by Nakoda Enterprises, Indore, Madhya Pradesh. Send Email 07942549275 79% Response Rate

More

SikaGrind®-455 GNT Cement Grinding Aids Sika Canada

The dosage rate of SikaGrind®-455 GNT will depend on desired characteristics of each type of cement. Dosage rates typically range from 0.02 % to 0.08 % by weight of cement for Types GU MS cements and from 0.03 % to 0.09 % by weight of cement for Type HE cements. The optimum dosage rate should be determined during full-scale cement mill tests.

More

OPTIMIZATION OF CEMENT GRINDING OPERATION IN BALL MILLS

Condition in one of the grinding chambers of the mill . Results of Optimization . The graphical analysis presented in Figure 2 represents progress of grinding along the length of the mill after optimizing the grinding process. rogress of grinding is clearly visible in Desired p the graphs. Figure -2: Analysis of longitudinal samples.

Morenotre force dans le broyeur et carrière

- stone crusher plant germany html

- spcifications de la machine du moulin

- entreprises de concassage de minerai de fer en indonésie

- Concasseurs Pièces de Rechange

- vente utilise broyeur a ciment vertical

- arabie saoudite entretien

- usine de concassage de dolomite de pain

- mouche briques de cendres processus de fabricationles ventes de ciment

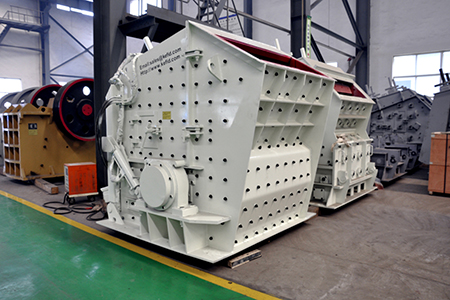

- concasseur à percussion de 1200 1500prix

- importante usine de raymond en utilisant la technologie de pointe

- Grande capacité pour le mini broyeur à percussion en pierre à vendre

- station de concassage mobile sur chenilles zelaishi

- iconcasseur et séparateur de métaux industriels

- fabricants de pulvérisateurs en chine

- rod moulin pour le cuivre usine de production