hammer mills fabrication

Design, Fabrication, and Performance Evaluation of a Hammer Mill

designed and fabricated hammer mill comprised of the milling chamber, grits outlet, suction fan, cyclone separator, prime mover, and frame. The hammer mill was evaluated at different

More

Design, Fabrication, and Performance Evaluation of a

2021年9月16日 The designed and fabricated hammer mill comprised of the milling chamber, grits outlet, suction fan, cyclone separator, prime mover, and frame.

More

(PDF) Design, Fabrication and Testing of a Direct Drive Electric ...

This research designed, fabricated and tested a direct drive electric powered hammer mill machine. A 3 HP electric motor with speed of 1800 rpm was used to power the mill. The

More

Design and Fabrication of a Hammer Mill for Domestic Use - IJRPR

Hammer mills are designed to crush and refine compact farm produce. They are used for various tasks, including turning dry yam into powder, cassava tubes into flour, maize into fine particles,

More

MODELLING AND FABRICATION OF POWER HAMMER MACHINE

designing and constructing a modified hammer milling machine to meet the increasing demand for cassava flour in bakery industries, addressing the limitations of existing mills. The work

More

13 SERIES - Schutte Hammermill

2019年2月13日 13 Series is an industrial hammer mill able to process a variety of materials to the exact desired particle size required, and convey the finished product to storage. Special

More

Design of hammer mills for optimum performance

2012年8月28日 In hammer mills, the grinding process consists of hitting the material by hammers, articulated on a rotor. It is important, however, that the percussions applied to the

More

Design and Fabrication of a Bone Crushing

This study focuses on the design and construction of an improved crushing machine with a capacity of 0.15 (150 kg/hr) tons per hour, 15 Hp, and 2910 rpm speed. The design follows criterion design guidelines to ensure the improved

More

DESIGN, FABRICATION AND TESTING OF A LABORATORY SIZE

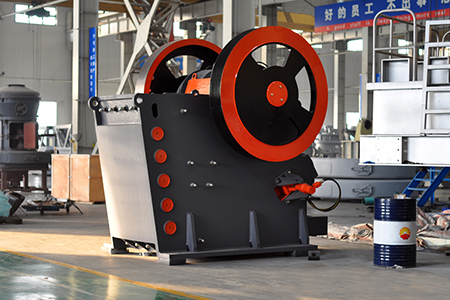

The laboratory size hammer mill was fabricated from locally available materials for crushing of minerals such as calcite, dolomite, limestone, granite and other materials of medium hardness.

More

Design, Fabrication, and Performance Evaluation of a Hammer Mill

Hammer Mill for Small-Scale Corn Milling Operation Erickson N. Dominguez Instructor, Department of Agricultural and Biosystems Engineering, College of Engineering, Benguet State University,

More

Design, construction and performance evaluation

2018年7月19日 This led to the design and fabrication of a modified hammer mill machine with a flat screen. The hammer mill is a power mill making use of a high-speed rotating disc, ...

More

Design and Fabrication of a Bone Crushing

This study focuses on the design and construction of an improved crushing machine with a capacity of 0.15 (150 kg/hr) tons per hour, 15 Hp, and 2910 rpm speed. The design follows criterion design guidelines to ensure the improved

More

Hammer Mill 1 PDF

This document summarizes research on improving the design, construction, and testing of a hammer mill. Key points: 1) The researchers redesigned and constructed the hammer mill beater, chamber, and shaft. They incorporated a gasoline engine directly to power and vary the speed of the beater. 2) Materials and methods used in construction included MS plate, angle

More

Hammer Mills – Rightway Manufacturing

R.W. Manufacturing, Inc. 1506 South Wood Street Stuttgart, AR 72160 (800) 866-6455 Toll Free (870) 673-7226 Local

More

DESIGN AND EVALUATE OF A SMALL HAMMER MILL

2015年12月18日 Schematic of design hammer mill 1-Main frame ,2-Single phase Electrical motor 1 k Watt, 3-Hammer mill housing ... show ed the machine after fabrication. Fig. (1): Schematic of design hammer mill .

More

Design, Fabrication and Performance Evaluation of a Hammer Cum Burr Mill

to a single-unit operation in which the works of the hammer and the burr mills can be performed simultaneously in a single operation. This study is therefore on the design, fabrication and performance evaluation of hammer cum burr mill. 1.1 Research Objectives The objectives of this study are: 1. to design hammer cum burr mill.

More

DESIGN AND FABRICATION OF A HAMMER MILL FROM LOCALLY SOURCED MATERIALS ...

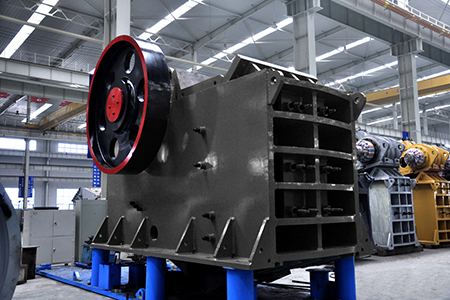

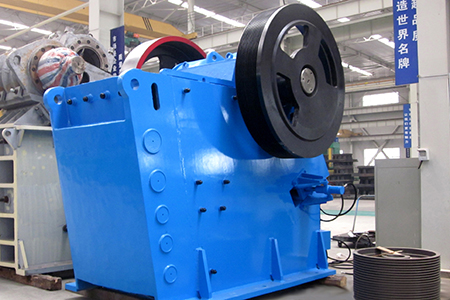

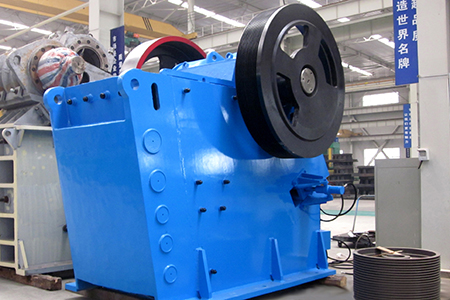

The machine consists of number of steel hammers radially and axially spaced on a shaft or rotor which rotates at a high speed in a strong housing. As the grain is fed into the mill from a feed hopper, the hammer strike it with a great force and rapidly pulverize it. The capacity of the hammering unit is 113.049kw with a milling efficiency of 85%.

More

Fabrication - Lancaster Parts Equipment

MACHINING CNC MILLING: Our CNC milling capabilities include a 2020 HAAS 4 axis mill 50″ X 20″ X 25″ . CNC TURNING: Our Tsugami M08SY-II dual spindle CNC lathe features live tooling, y-axis, and bar feeder for up to 2.60″ diameter material.. The large Doosan lathe has the ability to handle parts as large as 30″ in diameter, with 80″ between centers, and a 4.75″ spindle bore.

More

Hammer Mill Wear Parts » Red Dog Linings

Hammer Mill Wear Parts. As the world is rightly seeking to re-use and recycle all types of materials, the primary operation of Hammer mills is an arduous area where Red Dog Linings’s long life solutions and materials are second to none.

More

Design and Fabrication of a Bone Crushing

This study focuses on the design and construction of an improved crushing machine with a capacity of 0.15 (150 kg/hr) tons per hour, 15 Hp, and 2910 rpm speed. The design follows criterion design guidelines to ensure the improved

More

(PDF) Design, Fabrication and Testing of a Direct Drive Electric ...

2019. The performance of a hammer mill fabricated in Uganda was evaluated and the optimal performance conditions were determined. The evaluation was done with screen hole diameters (S) of 1.5, 2.0, and 3.0 mm, hammer tip speeds (H) of 68.12, 81.81, 102.17 m s and hammer thicknesses (T) of 4.0, 5.0, and 6.0 mm for determination of energy consumption and

More

DESIGN AND FABRICATION OF A HAMMER MILL FROM LOCALLY SOURCED MATERIALS ...

The machine consists of number of steel hammers radially and axially spaced on a shaft or rotor which rotates at a high speed in a strong housing. As the grain is fed into the mill from a feed hopper, the hammer strike it with a great force and rapidly pulverize it. The capacity of the hammering unit is 113.049kw with a milling efficiency of 85%.

More

Redesign and Fabrication of Hammer Milling Machine for

2019年1月1日 Mill types were a hammer mill (HM, sieve size 3 and 5mm), a crimping roller mill (RM1, gap between rolls 0.5 and 0.8mm), a flattening roller mill (RM2, gap between rolls 0.15 and 0.35mm) and a ...

More

DEVELOPMENT OF A HORIZONTAL SHAFT HAMMER MILL CHAPTER

A hammer mill has been designed with due considerations to standard design requirements and cost to cater to this need. ... 27 1.6 Scope of the study This study covers the design fabrication and testing of a horizontal shaft hammer mill for crushing medium hard materials like, limestone, ...

More

PHILIPPINE AGRICULTURAL ENGINEERING STANDARD PAES 216:

PAES 216:2004 B-53 7.6 The hammer mill shall be free from manufacturing defects that may be detrimental to its operation. 7.7 Any uncoated metallic surfaces shall be free from rust and shall be painted properly. 7.8 The hammer mill shall be free from sharp edges and surfaces that may injure the operator. 7.9 Belt cover or guard and provisions for belt tightening and adjustments

More

Design and Evaluation of Crushing Hammer mill - ResearchGate

2019年1月1日 A grain size reduction hammer mill for crushing corn (Zea mays L.) was designed depending on variety characteristics and by using computer aided design “ANSYS” software.

More

Full article: Optimizing hammer mill performance through

2014年4月9日 There are numerous hammer designs available in industry, variations in hammer mill drum speeds and many combinations of screen selection in multiple stage processes to be considered. In this paper, the authors have investigated screen size, drum speed, hammer design and crop type to determine if there are indeed strategies that can be used to decrease the cost

More

Design, construction and performance evaluation of a flat screen hammer

2018年7月19日 This led to the design and fabrication of a modified hammermill machine with a flat screen. The hammer mill is a power mill making use of a high-speed rotating disc, which is stationary to a number of hammer bars that move superficially by a centrifugal force.

More

MODELLING AND FABRICATION OF POWER HAMMER

hammer mill with a double sieving device for grinding grains and agricultural products, using locally available materials. (Akash Santosh Pawar, 2021) focused on the manufacturing, design, and analysis of a hammer mill machine and its rotor assembly with a capacity of 200 kg/hr. (Ezurike et al., 2018) designed,

Morefabricants de broyeur à boulets de ciment

- Marocn broyeur de pierres

- concasseur a c ne cs norberg scs serie

- La capacité de concassage portable Chine

- Bouteille concasseur à Pretoria

- concasseur à cne cordoba

- pièces de concasseurs sayaji utilises

- Chungu Gros Concasseur A Shanghai Co Ltd

- SBM modèle moteur broyeur

- Liste des prix des moulins o

- Of Balls dans les usines de ciment principes de fonctionnement de

- broyeur de pierre primaire utilisé au royaumeuni

- propriétés fabriquées de sable

- puits de transmission dans les ecrans vibratoires

- coût le minerai de fer de l'usine d enrichissement

- Fabricants Chinois De Broyeur De Recyclage Mobile results