power plants and coal mills

Coal mill pulverizer in thermal power plants PPT

2012年11月17日 The document discusses coal mill/pulverizers used in thermal power plants. It describes how pulverized coal is dried, ground, circulated, and classified within the mill to produce a fine powder that is then transported to

More

Derivation and validation of a coal mill model for control

2012年5月1日 The paper presents development and validation of a coal mill model to be used for improved mill control, which may lead to a better load following capability of power plants

More

Advanced monitoring and process control technology for coal

2010年1月1日 This chapter describes the current state in the development of monitoring and control technologies for applications in coal-fired power stations. Monitoring issues that are

More

An investigation of performance characteristics and

2020年8月12日 In a power plant, the coal mill is the critical equipment, whose effectiveness impacts the overall power plant efficiency. Uniform coal feeding mass flow rate and required particle...

More

Combining solar power with coal-fired power plants, or cofiring

2018年3月7日 As part of increasing electricity supply in the region, a 5-MW coal-solar hybrid project is being developed by Engie and Solar Power at the existing 320-MW Mejillones coal

More

Global site-specific health impacts of fossil energy, steel mills, oil ...

2023年8月22日 The power plant part of this emission site database comes from the commercially available Platts World Electric Power Plant (WEPP) database 31, which

More

Thermal power plant as contributed by coal mill control

Abstract: In recent years, the load following capability of thermal power plants has been actively researched, as power system interconnection unavoidably brings about complicated load

More

Predictive control strategy for a supercritical power plant and

Predictive control strategy for a supercritical power plant and study of influences of coal mills control on its dynamic responses. Abstract:The paper is to investigate dynamic responses of

More

Review of flexible operation of coal-fired power plants - ICSC

flexibly, as wind and solar energy plants are likely to operate ahead of them Studies are providing indications of how flexible operation of coal-fired C02 capture plants could be realised

More

Britain calls time on coal power, steel mills

2024年10月1日 London Britain closed a chapter of its storied but carbon-heavy industrial history, as its last coal-fired power plant was switched off and its largest steel mill was shuttered.. Tata Steel on ...

More

Coal and Mill PDF Mill (Grinding) Mechanical

Coal and mill - Free download as PDF File (.pdf), Text File (.txt) or view presentation slides online. The document discusses pulverized coal mills used in power plants. It describes different types of mills including tube mills, ball

More

What Types of Coal Mills are Used in Power Plants?

2.Tube Mills: Tube mills, or tubular mills, are another type of coal mill used in power plants. These mills consist of a rotating tube filled with steel balls or steel rods. As the tube rotates, the balls or rods crush and grind the coal. Tube mills are known for their high capacity and low energy consumption.

More

Coal Mill in Thermal Power Plant: Enhancing Efficiency and

Bellian Machinery leads the industry in providing high-quality coal mills for thermal power plants. With enhanced grinding efficiency, reliable and safe operation, precise control, low maintenance requirements, and commitment to environmental sustainability, Bellian Machinery's coal mills are revolutionizing coal milling in thermal power plants ...

More

Coal Pulverizer – Power Plant Pall Corporation

Power generation industry studies have shown that pulverized coal power plants are an area where improved equipment reliability is essential. The Electric Research Institute (EPRI) has determined that 1% of plant availability is lost on average due to pulverizer-related problems.

More

MRHS - Mill Reject Handling System in Thermal Power Plant

MRHS automatically discharge the iron pyrite and other non‐grind‐able material from coal mill through an outlet connection to the ... COAL HANDLING PLANTS. A Comprehensive Guide to Thermal Power Plant And Bulk Material Handling Equipment. ARTICLES LIBRARY; LATEST ARTICLES; QUESTIONS ANSWERS; ... The mode of operation is same for all mills.

More

Coal Mill in Thermal Power Plant PDF Mill (Grinding) - Scribd

Coal Mill in Thermal Power Plant - Free download as Word Doc (.doc / .docx), PDF File (.pdf), Text File (.txt) or read online for free. This document discusses coal pulverizers/mills which are critical components that convert the stored energy in coal into electricity. There are various types of pulverizers that primarily utilize grinding, drying, classification and circulation processes.

More

Observer and Data-Driven-Model-Based Fault Detection in Power Plant

2008年4月30日 This paper presents and compares model-based and data-driven fault detection approaches for coal mill systems. The first approach detects faults with an optimal unknown input observer developed from a simplified energy balance model. Due to the time-consuming effort in developing a first principles model with motor power as the controlled

More

Effect of Coal Quality and Performance of Coal pulverisers / Mills

2021年3月31日 3. COAL QUALITY –IMPACT- COMPLEX • Pulverizer capacity, fineness wear • Slagging fouling in boiler • Corrosion erosion in boiler • Ash characteristics affect efficient collection in ESP. • Affects furnace convective pass heat absorption boiler availability . • Quantification of impact is complex. 31-Mar-2021 total output power solutions 3

More

Home - GPL

To be a premier global service provider for Coal Pulverizer Mills working in Thermal power Plants as per international standards with consistent growth rate, providing more value for money. Our Team. ... Engineering, and servicing for Coal Pulverizers RP, RPS, HP Mills form 603 to 1203 size used in 60 MW to 800 MW Power Projects.

More

Global site-specific health impacts of fossil energy, steel mills, oil ...

2023年8月22日 The power plant part of this emission site database comes from the commercially available Platts World Electric Power Plant (WEPP) database 31, which provides data on 125,000 coal, gas and oil ...

More

Online analysis and coal-fired power plants - ICSC

The coal-based, power generation process has many stages that require data monitoring and analysis. Figure 1 shows a layout of a coal-fired power plant and Table 1 lists the various stages in such a facility. In this report, online analysers used in stages 1 to 6 will be discussed. Continuous coal-flow measurement and control application (stage ...

More

Pulverizers 101: Part I - POWER Magazine

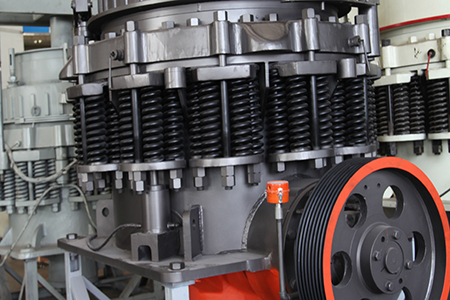

2011年8月1日 A typical MPS-89 pulverizer found in many coal-fired power plants. ... We have seen mills assembled with unmatched sets of three grinding journals using maximum spring pressure.

More

Coal Mill in Thermal Power Plant PDF Mill (Grinding) - Scribd

Coal Mill in Thermal Power Plant - Free download as Word Doc (.doc / .docx), PDF File (.pdf), Text File (.txt) or read online for free. This document discusses coal pulverizers/mills which are critical components that convert the stored energy in coal into electricity. There are various types of pulverizers that primarily utilize grinding, drying, classification and circulation processes.

More

China finds coal a hard habit to break as power plants, steel mills ...

2022年2月24日 The coal-based steel mills initiated in 2021 will entail US$70 billion to US$110 billion in stranded assets when carbon emission reduction targets are realised, and the coal power plants imply a ...

More

INVESTIGATION ON CLASSIFICATION EFFICIENCY FOR COAL-FIRED POWER PLANT

angle on the classification efficiency in Coal-Fired power plants. The gas flow inside the coal mill was solved by the realizable k -ε turbulence model (RKE) with a detailed 3-D classifier geometry meanwhile the discrete phase model was used to solve the coal particles flow. The steepest classifier blade angle of 40 o achieved

More

classifications and working of mills in a power plant PPT

2020年6月29日 6. TYPES OF COAL PULVERIZER • Tube or ball mills: Low-speed machines that grind the coal with steel balls in a rotating horizontal cylinder. If the diameter of the cylinder is greater than the length of the cylinder, the mill is called a ball mill. If the length of the cylinder is greater than the diameter of the cylinder, it is called a tube mill.

More

Combining solar power with coal-fired power plants, or cofiring

Operators of coal-fired power plants seek ways to increase the efficiency and extend the working lives of their plants by improving the operational flexibility and reducing the environmental impact. Two possible options are explored: combining solar energy with coal-fired power generation, and cofiring natural gas in coal-fired power plants.

More

Expert systems and coal quality in power generation - USEA

a power plant including the coal handling facilities, pulverising mills, boiler, air heater, ESP, ash disposal as well as stack emissions. Figure 1 is a diagram of a typical pulverised coal combustion power station. Table 1 is the stages that require monitoring in a coal-fired power generating plants (as shown in Figure1).

More

FAULT DETECTION IN COAL MILLS USED IN POWER PLANTS

2006年1月1日 In order to achieve high performance and efficiency of coal-fired power plants, it is highly important to control the coal flow into the furnace in the power plant. This means suppression of disturbances and force the coal mill to deliver the required coal flow, as well as monitor the coal mill in order to detect faults in the coal mill when they emerge.

Moreo processo de moagem isdry

- broyeur à boulets d occasion pour peintures vadodara

- effet du concassr sur le tertiaire

- concasseur à marteaux à double anneau efficace à vendre

- exploitation et de traitement de minerai d'hematite

- petite pierre liste de prix de concasseur

- Rock fabricants de concassage

- lampe de broyeur de charbon

- usines de concassage de dolomite en angleterre

- zhenghong minerai machines de dressage machines

- raymond custo de capital moinho

- moulin échantillon soupape de certificat de test

- opération mark 6 rock crusher

- 2 micron poudre de ligne broyage moulin

- animasi conique broyeur à boulets

- broyeur à percussion capacité de 10 cubes