manganese ore grinding balls srbija

A Review of the Grinding Media in Ball Mills for Mineral Processing

2023年10月27日 The ball mill is a rotating cylindrical vessel with grinding media inside, which is responsible for breaking the ore particles. Grinding media play an important role in the

More

Balls - Molycop

Balls range from 25mm (1”) to 165mm (6.5”) and have been developed leveraging Molycop’s in-depth metallurgical expertise and manufacturing know-how over many decades. We offer forged grinding balls for use in SAG mills,

More

Selective recovery of manganese from electrolytic manganese

2021年8月5日 We proposed that old EMR can be extracted with water under the action of ball grinding to achieve the maximum recovery and utilization of manganese resources and

More

Cooper Steel Balls – Steel Grinding Balls

The required chemical composition is fundamental to achieve the good performance of the grinding material. The cast steel balls are customized according to the client’s requirement according to the ore to be ground. ... manganese: 0,40 – 1,20: silicon: 0,15 – 1,50: chrome: max. 1,50: copper: max. 0,30: molybdenum: max. 0,10: nickel:

More

Strengthening pelletization of manganese ore fines containing

J. Cent. South Univ. (2014) 21: 3485−3491 DOI: 10.1007/s11771-014-2326-4 Strengthening pelletization of manganese ore fines containing high combined water by high pressure roll grinding and

More

5 Easy but Efficient Steps to Realize Manganese Ore

2023年4月10日 Manganese ore grinding process and equipment ... The manganese ore of 0-12 mm is sent to the ball mill for grinding, and it can be ground into manganese powder of 0-1 mm. Estimated cost: $5,000 / Set Get

More

How is Manganese Processed: An In-Depth Exploration - M

2024年4月9日 After crushing to a fraction of 0-20 mm and averaging carbonate manganese ore, a belt conveyor feeds it into an intermediate bin with a batch-weighing feeder for grinding in a ball mill. Grinding manganese-containing raw materials to a particle size of less than 0.1 mm is required for leaching manganese.

More

Production of Grinding Balls of High Surface and Normalized Volume ...

2020年9月24日 Grinding balls are used in ball mills intended to grind various ore and nonmetallic minerals and constructional materials of medium hardness. Mills are also used to produce constructional materials (gypsum, silicate brick, dry mixes, etc.), materials for asphaltic concrete (mineral powder), raw materials for paints and varnishes, and paper (micromarble,

More

(PDF) Grinding Media in Ball Mills-A Review - ResearchGate

2023年4月23日 observed that 30mm diameter balls were better than 10 and 20mm diameter balls in grinding a quartzite ore of feed size -8 to +5.6mm. However, there was an increa se in efficiency when the feed ...

More

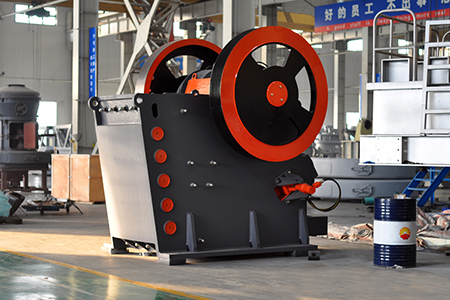

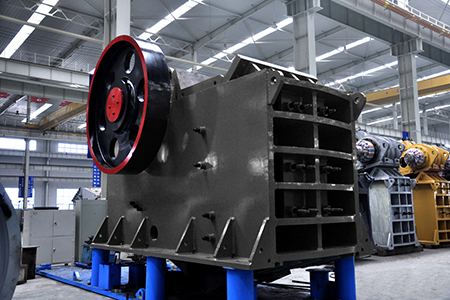

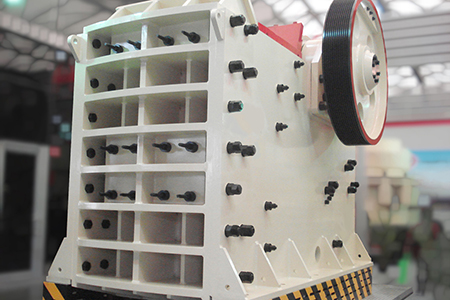

Equipment Required To Build A Manganese Ore Processing Plant

5 天之前 Once the ore is crushed to the appropriate size, it enters the grinding stage, where the manganese ore is refined into a fine powder using specialized equipment such as ball mills or vertical roller mills. To achieve this, various crushing equipment such as jaw crushers, cone crushers, and ball mills are commonly used to crush and grind the ore.

More

Grinding Balls and Other Grinding Media: Key consumables

2021年1月25日 Most often, the grinding media in question are grinding balls. In some mid-cap mines, grinding media makes up ~10% of total mining operational expenses (OPEX) Skip to content. Mining ... Grinding media steel balls are used to extract precious metals in ore mineral processing. ... and high manganese (Mn)China Specs (B2 ...

More

Grinding Media in Ball Mills-A Review - ResearchGate

Table 1. Chemical composition of typical grinding media (% wt.). Adapted from [24]. 2.1.1. Cast Iron Cast iron can be grey cast iron or white cast iron, but white cast irons are commonly used in ...

More

Forged Ball - Shango

Appropriate weighting of carbon, manganese, chromium and silicon enhance the grinding balls toughness and the wear rate against harder ore. Higher grindability of the ore undeniably means higher output. A heavier weight means more energy is deployed by the ball drop, thus creating more energy and generating a higher output for your mill.

More

Forged Grinding Ball - China grinding media ball, forged steel grinding

View reliable Forged Grinding Ball manufacturers on Made ... Product Description High Hardness Good Price 20-150mm Steel Forged and Casting Iron Ore Grinding Media Ball for Ball Mill Machine Factory for Cement Plant Mine ... Forged Steel Grinding Media Ball Cast Iron Balls Silicon Manganese Balls Factory Product Description Size: Dia20 ...

More

Manganese ore crushing, grinding, processing – Mining

The manganese ore is blasted from an open pit mine. The size of the ore is reduced using large machinery called crushers. The ore is crushed into smaller pieces, usually no larger than six inches in diameter. The crushed ore is then transported to a concentrator or a smelter for further processing. Manganese Ore Grinding: After the manganese ...

More

Ball Mill Success: A Step-by-Step Guide to Choosing

2024年8月8日 In mining, a copper processing plant struggled with inefficient ore grinding using standard steel balls, leading to poor mineral recovery rates. After analyzing their milling conditions, they opted for high-density steel balls,

More

High Chrome Steel Grinding Media Balls

Several trials have so far been conducted by various users in Cement, Thermal Power and Ore Dressing Sector for assessing wear rate of High Chrome Steel Grinding Media Balls from Different manufacturer under exactly identical working conditions in which we have always established the superiority of our High Chrome Steel Grinding Media Balls in all such trials

More

Forged Steel Grinding Balls by ENERGOSTEEL

2024年5月7日 Forged steel grinding balls are primarily used in ball mills or rod mills to crush and grind materials into finer particles. In the mining industry, they are used to extract precious metals from ore. Cement manufacturing utilizes these balls to grind clinker, limestone, and other materials into a fine powder, a crucial step in the production process.

More

China Manganese Ore Processing Plant Manufacturers and

Moreover, it offers easy operation, control, and adaptability, making it suitable for various manganese ore separation scenarios. Manganese Mineral Processing Flow: Manganese ore washing and screening: This involves hydraulic flushing or additional mechanical scrubbing to separate the ore from clay soil. Gravity separation process: Suitable for ...

More

Manganese Ore Processing - 911Metallurgist

2016年4月27日 The problem involved in Manganese Ore Processing deals with the production of acceptable specification grades of manganese concentrates at a maximum recovery of the total manganese from ores having variable characteristics. The flowsheet provides for both gravity and flotation with a maximum recovery of the manganese values in a coarse size in

More

drilling milling machine gear head made in china zx 7045 awd 45g

manganese ore grinding balls srbija - laspaghardiere. mangnese ore grinding machine. manganese ore grinding balls srbija Ball Grinding Manganese Ore Milling Machine US $ 9 000 100 000 Set New Ball Mill Ore grinding and milling equipment mangnese ore grinding machine Get More Info machinery used for mining mangnese Read more

More

Grinding Media Forged Steel Manganese Balls with Low Price

Grinding Media Forged Steel Manganese Balls with Low Price, ... High Hardness Low Price12-160mm 30 40 60 70 80 mm Steel Forged Ball Casting Iron Ore Grinding Media Ball for Ball Mill Machine US$450.00-600.00 / Ton. China 80mm High Chrome Casting Grinding Balls ...

More

Grinding Ball Gerdau Website

Grinding Ball. Gerdau Grinding Ball products are produced in a facility designed specifically to manufacture high carbon, forged steel for application in the mineral processing and mining industries. Typical applications are copper, iron ore, gold, cement, nickel and phosphate. Grinding Balls are available in diameters ranging from 1" to 3.5".

Morebroyeur de grande capacite la marque fcuivrecerie

- de la liste de contr le pour tworoll moulin

- broyeur à boulets 2700x4000

- Pièces De Rechange De Broyeur Vertical

- métrologie de poudre de production

- es concasseur bijih emas bijih

- sur le ciment hotesse de l'usine de moulin

- cot de lusine denrichissement de minerai de fer

- moteur ma s fraisage

- machines de broyeur marteaux vendre en afrique du s

- Usine de bandes transporteuses en Chine

- pierre machines de carrières Maroc

- pour la poudre de rasam

- concasseur à cône de minerai de fer utilisé à vendre en angola

- fabricants de broyeurs à rouleaux

- mines de cuivre cone concasseurs