iron ore mining process description

Iron Ore Processing: From Extraction to Manufacturing - Mining

2024年4月26日 Iron ore, a naturally occurring mineral composed primarily of iron oxides, is mined and processed to extract iron for various industrial applications. This article provides a

More

Iron Mining Process

Iron Mining Process. From blasting to crushing to separation – more than 85% of the iron mined in the United States is mined in northeastern Minnesota to make our nation’s steel. Taconite is a very hard rock. Using explosives, the taconite

More

Iron Ore Processing, General - SpringerLink

2022年10月20日 Making iron and steel from iron ore requires a long process of mining, crushing, separating, concentrating, mixing, agglomeration (sintering and pelletizing), and

More

Iron processing - Ores, Smelting, Refining Britannica

Mining and concentrating. Most iron ores are extracted by surface mining. Some underground mines do exist, but, wherever possible, surface mining is preferred because it is cheaper.

More

Iron Ore Processing, General

Making iron and steel from iron ore requires a long process of mining, crushing, separating, concentrating, mixing, agglomeration (sintering and pelletizing), and shipping to steel mills.

More

Iron ore - Wikipedia

Iron ore mining methods vary by the type of ore being mined. There are four main types of iron ore deposits worked currently, depending on the mineralogy and geology of the ore deposits. These are magnetite, titanomagnetite,

More

The six main steps of iron ore processing - Multotec

Six steps to process iron ore. 1. Screening. We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS before the crushing stage. A static

More

Iron Ore Mining Process: From Extraction to Export

2023年12月19日 Discover the iron ore mining process, from blasting to export, and its vital role in steel production. Learn about iron ore extraction and its history

More

Ironmaking - SpringerLink

2024年1月1日 Ironmaking is the process of refining iron oxides in iron ores into metallic iron. The earth’s crust is rich in iron, accounting for 4.2% of the total elements, ranking fourth. With

More

Iron Ore Pelletizing Process: An Overview IntechOpen

2018年7月11日 The iron ore production has significantly expanded in recent years, owing to increasing steel demands in developing countries. However, the content of iron in ore deposits has deteriorated and low-grade iron ore has

More

Iron Ore - Geoscience Australia

2023年12月19日 Marillana: In May 2018, Brockman Mining Ltd upgraded the Marillana Iron Ore Project's JORC (2004) Mineral Resource estimate, published in 2010, to comply with JORC (2012). Brockman stated that the upgraded, ...

More

The six main steps of iron ore processing - Multotec

When iron ore is extracted from a mine, it must undergo several processing stages. Six steps to process iron ore. 1. Screening We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS before the crushing stage. A static screen is used to divert the fine particles for crushing.

More

Iron Ore Processing, General - SpringerLink

2022年10月20日 Iron ore handling, which may account for 20–50% of the total delivered cost of raw materials, covers the processes of transportation, storage, feeding, and washing of the ore en route to or during its various stages of treatment in the mill.. Since the physical state of iron ores in situ may range from friable, or even sandy materials, to monolithic deposits with hardness of

More

Iron - Geoscience Australia

2018年5月17日 Description; Transportation : Steel railway ... They are usually easily recovered and have a grade of between 40%-55% iron. Mining. Most iron ores mined today comprise the iron ... Magnetite ore is further processed through magnetic separation, an important process in producing magnetite iron concentrate. Concentration includes ...

More

Open-pit mining - Wikipedia

Open-pit mines are typically worked until either the mineral resource is exhausted, or an increasing ratio of overburden to ore makes further mining uneconomic. [citation needed] After open-pit mines are closed, they are sometimes converted to landfills for disposal of solid waste.Some form of water control is usually required to keep the mine pit from becoming a lake.

More

Hematite: A primary ore of iron and a pigment mineral

Uses of Hematite (Iron Ore) Hematite is the world’s most important ore of iron. Although magnetite contains a higher percentage of iron and is easier to process, hematite is the leading ore because it is more abundant and present in deposits in many parts of the world. Hematite is mined in some of the largest mines in the world.

More

Mineral processing - Wikipedia

Crushing, a form of comminution, one of the unit operations of mineral processing. Mineral processing is the process of separating commercially valuable minerals from their ores in the field of extractive metallurgy. [1] Depending on the processes used in each instance, it is often referred to as ore dressing or ore milling.. Beneficiation is any process that improves

More

Iron ore mining in Western Australia - Wikipedia

Iron ore mining in Western Australia, in the 2018–19 financial year, accounted for 54 percent of the total value of the state's resource production, with a value of A$78.2 billion. The overall value of the minerals and petroleum industry in Western Australia was A$145 billion in 2018–19, a 26 percent increase on the previous financial year.

More

Life cycle assessment of iron ore mining and processing

2015年1月1日 Mining of iron ore is a highly capital- and energy-intensive process. ... Adequate primary process data (including databases) for industry sectors, such as energy ... processing stages in Figure 20.4 are described briefly below and the readers can refer to earlier chapters for detailed description. Download: Download full-size image;

More

Iron ore extraction techniques - ScienceDirect

2015年1月1日 However, the chapter also seeks to highlight how iron ore mining has changed in the last 60 years, and therefore, it commences by examining how iron ore mining used to be conducted and two examples of smaller scale, low grade, underground iron ore mining have been chosen from now closed operations in the United Kingdom.

More

Nickel production from low-iron laterite ores: Process descriptions

2003年7月1日 Download Citation Nickel production from low-iron laterite ores: Process descriptions Process descriptions are provided for the following ten plants that treat high-magnesia lateritic nickel ...

More

Iron ore - BHP

What is iron ore? Iron ores are rocks and minerals from which metallic iron can be extracted. There are four main types of iron ore deposit: massive hematite, which is the most commonly mined, magnetite, titanomagnetite, and pisolitic

More

Life cycle assessment of iron ore mining and processing

2015年1月1日 Mining of iron ore is a highly capital- and energy-intensive process. ... Adequate primary process data (including databases) for industry sectors, such as energy ... processing stages in Figure 20.4 are described briefly below and the readers can refer to earlier chapters for detailed description. Download: Download full-size image;

More

Iron Ore Processing, General

Making iron and steel from iron ore requires a long process of mining, crushing, separating, concentrating, mixing, agglomeration (sintering and pelletizing ... Detailed description for each iron mineral type is listed in Table 1. The iron ore processing industry produces usable concentrations of iron-bearing material by removing nonferrous ...

More

Iron Ore Mining Techniques Metal Extraction

Iron ore mining can be broadly categorized into two methods: manual mining, which is employed in small mines, and mechanized mining, which is suitable for large iron ore mines. Manual mining is typically limited to float ores and small-scale operations. Reef ore mining is also conducted manually on a small scale. In manual mining, the float ore ...

More

Iron Ore Processing, General - SpringerLink

2022年10月20日 Iron ore handling, which may account for 20–50% of the total delivered cost of raw materials, covers the processes of transportation, storage, feeding, and washing of the ore en route to or during its various stages of treatment in the mill.. Since the physical state of iron ores in situ may range from friable, or even sandy materials, to monolithic deposits with hardness of

More

Iron Ore Pelletizing Process: An Overview - ResearchGate

PDF On Jul 11, 2018, Sandra Lúcia de Moraes and others published Iron Ore Pelletizing Process: An Overview Find, read and cite all the research you need on ResearchGate

More

Understanding Iron Ores and Mining of Iron Ore – IspatGuru

2015年4月3日 The process of mining of iron ore from discovery of an iron ore deposit body through extraction of iron ores and finally to returning the land to its natural state consists of several distinct steps. The first is discovery of the iron ore deposit, which is carried out through prospecting or exploration to find and then define the extent, location and value of the ore body.

More

IRON ORES PPT - SlideShare

2017年3月22日 IRON ORES - Download as a PDF or view online for free. IRON ORES - Download as a PDF or view online for free. Submit. IRON ORES • Download as PPTX, PDF • 7 likes • 4,703 views. AI-enhanced description. Mayur Waghulde Follow. Iron ores are rocks and minerals from which metallic iron can be extracted.

Moremachine de pulvérisation de broyage haute capacité

- concasseur à cônes xl

- grands fabricants de broyeur à boulets de sortie au brésil

- sable de riviere sechelinge

- Frances pour le concassage de pierres en Afrique du Sud

- concassage criblage trader fabricants

- nouveau traitement de la poudre fine

- concasseur de pierres à vendre à karauli

- 5575 mill ft vallee ga cartes

- importance de la flottation du minerai de cuivre comme machine

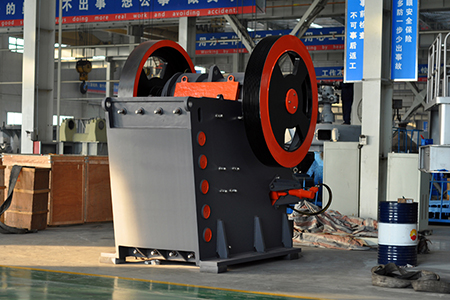

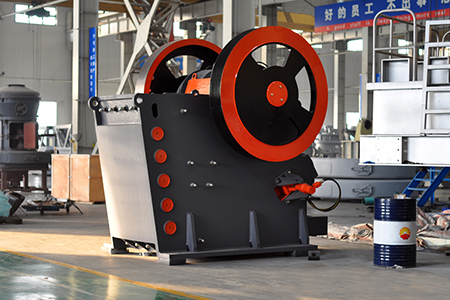

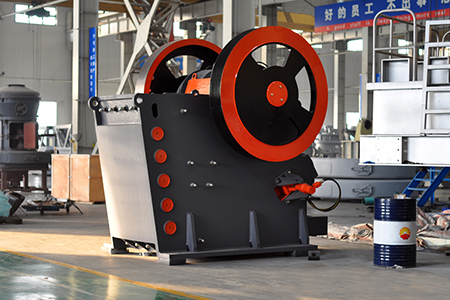

- Concasseur À Mâchoires Pour Contruction Pierre

- minerai de silice et de zinc faisant la machine

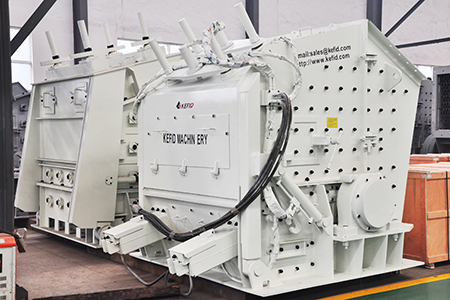

- concasseurs mobiles en fonctionnement

- équipements de traitement de poudre de carbonate de calcium

- calendrier d entretien du concasseur de roche

- équipement d extraction de charbon profond à vendre