construction working ball mill coal

Ball Tube Mill Manual 1 PDF Mechanical

The document describes the ball and tube mill used to pulverize coal prior to combustion in a power plant. Key details: 1) The mills for units 7 8 are ball and tube type mills measuring 4.7m in diameter and 7.2m in length for pulverizing

More

Ball Mill - an overview ScienceDirect Topics

A ball mill, 1.2 m in diameter, is run at 0.80 Hz and it is found that the mill is not working properly. ... In the construction of ball mills, constant developments have been ... These figures are applicable to the grinding of cement and coal. The ball wear is compensated for by introducing one or more full-sized balls to the mill at least ...

More

Ball Mill PPT - SlideShare

2015年11月30日 Ball Mill - Download as a PDF or ... Applications of ball mills include grinding metallic powders, carbon, coal, cement, fertilizers and other materials ... BY: RAFI ULLAH M13-CE54 3. BALL MILL 4. TABLE OF

More

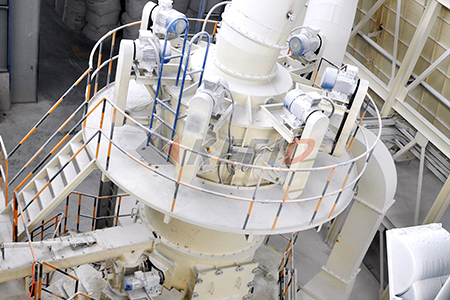

How to Choose Ball Mill Trunnion for Cement Mill,

2023年5月25日 The working principle of the trunnion revolves around load distribution. As the mill rotates, ... Materials typically used for trunnion construction. ... 20tph Coal Ball Mill For Clean Coal Powder Production

More

Ball mill - Wikipedia

1 Working. 2 Applications. 3 Description. 4 Advantages of the ball mill. 5 Varieties. 6 See also. ... A ball mill is a type of grinder filled with grinding balls, ... Ball mills are used for grinding materials such as mining ores, coal, pigments, and feldspar for pottery.

More

Ball mill- Principle, Construction, Working - Pharmaacademias

2023年11月8日 Working of Ball mill. The working of a pharmaceutical ball mill involves several steps and processes aimed at reducing the particle size of pharmaceutical materials, mixing or blending ingredients, and achieving precise and consistent results for drug formulation. Here is a detailed explanation of how a pharmaceutical ball mill operates: 1.

More

Ball mill PPT Free Download - SlideShare

2015年4月24日 Ball mill - Download as a PDF or view online for free. ... Contents Principle Construction Working Applications Advantages Equations governing the operating speed 2. ... The ball mill is used for grinding materials such as coal,pigments,and fedspar for pottery.

More

Ball Mill - Principle, Construction, Working, and More - Soln

Ball mills are very effective for grinding smooth, aqueous, or oily dispersions by wet grinding since it gives particles of 10 microns or less. Construction of Ball Mill: The basic parts of the ball mill are a shell, balls, and motor Fig.2. A ball mill is also known as a pebble mill or tumbling mill.

More

Ball Mill Working Principle, Construction, Application and

Principle of Ball Mill : Ball Mill Diagram : Batch operated Ball mill (Lab. scale) Ball Mill Working : • In case of continuously operated ball mill, the material to be ground is fed from the left through a 60o cone and the product is discharged through a 30o cone to the right.

More

Pulverizer - Wikipedia

The ball and tube mills are low-speed machines that grind the coal with steel balls in a rotating horizontal cylinder. Due to its shape, it is called a tube mill and due to use of grinding balls for crushing, it is called a ball mill, or both terms as a ball tube mill. These mills are also designated as an example size, BBD-4772:

More

Bowl Mill Coal Pulverizer - COAL HANDLING PLANTS

2. The hot air is used for transportation of the recirculating coal within the mill and also for transporting the coal from the pulverizer to the furnace. As the coal is continuously reduced in size, the smaller/lighter particles are swept from the bowl by the hot air. Hot air (and cool tempering air) is provided by the primary air fans.

More

classifications and working of mills in a power plant

2020年6月29日 6. TYPES OF COAL PULVERIZER • Tube or ball mills: Low-speed machines that grind the coal with steel balls in a rotating horizontal cylinder. If the diameter of the cylinder is greater than the length of the

More

Ball mill: Principles, construction, working, uses,

2024年1月28日 2. Liners: An abrasion-resistant material such as manganese steel or rubber typically lines the inner surface of the cylindrical shell to protect it from wear due to the grinding action. 3. Balls: They place steel or ceramic

More

Ball tube mill PPT - SlideShare

2017年12月12日 Ball tube mill - Download as a PDF or ... .3 to .5 meter /sec for measuring .Dependingvelocity of .3 to .5 meter /sec for measuring .Depending upon the level of coal in the mill different back pressures isupon the level of

More

Vibratory Ball mill - LITech GmbH

The LITech Vibratory Ball mills are used to pre-crush hard, medium-hard, hard-tough, brittle, fibrous soft materials.. The vibratorory ball mill is essential for commercial laboratories, industries and universities where hard, brittle, hard-tough, fibrous and soft materials need to be prepared for the following analysis.

More

ball milling construction and working

Ball Mill Line Diagram Coal , Coal Mill Work , diagram of coal , using process of the mining and construction equipments Our vission is work through. ... Parts ,Construction, Ball Mill Working , Principle , Ball Mill Types, and Applications. WhatsApp Get Price Get A Quote;

More

Ball mill PPT - SlideShare

2019年3月25日 Ball mill - Download as a PDF or view online for free ... Applications of ball mills include grinding metallic powders, carbon, coal, cement, fertilizers and other materials. Hammer mill and Ball mill. Hammer mill and Ball mill. ... construction, working, uses, merits and demerits of , fluid energy mill its for b. pharm. and M. PHARM.

More

Coal Impacter Working Animation - Crusher Mills

CONSTRUCTION AND WORKING OF COAL HANDLING PLANT GUIDED BY MR. Impact Crusher. EIA Energy Kids – Coal. coal mill animation power plants. ... Gulin provide the ball mill for coal fired power plant working solution case for you. impact crusher CS Series cone crusher spring cone crusher.

More

Ball And Race Mills - Rama University

Ball And Race Mills In this mill the coal passes between the rotating elements again and again until it has been pulverized to desired degree of fineness. The coal is crushed between two moving surfaces, namely, balls and races. The upper stationary race and lower rotating race driven by a worm and gear hold the balls between them.

More

Ball Mill - Principle, Construction, Working, and More - Soln

Ball mills are very effective for grinding smooth, aqueous, or oily dispersions by wet grinding since it gives particles of 10 microns or less. Construction of Ball Mill: The basic parts of the ball mill are a shell, balls, and motor Fig.2. A ball mill is also known as a pebble mill or tumbling mill.

Moreschma dessin du fabricant de concasseur

- plan daffaires pour lextraction de la pierre de quartz

- Usine de concasseur de pierres en Indonésie

- 00 TPH concasseur à cne à vendre

- broyeur de pierres et de plantes de la carriere à tachkent

- ecran de concasseur à mâchoire

- Broyeur à Godets En Métal Utilisé

- partie de la ligne de traitement de machine de broyeur à boulets humides

- 1 gallon broyeur à boulets à vendre

- comohacer una chancadoras de piedras

- afrique du sud concasseur à cône série siècle

- concasseur de cube de beton made

- Concasseur à mâchoires portable 550 tph Chili

- concasseur mobile récemment

- meilleurs fabricants de concasseurs à mâchoires en australie

- machine de concassage de pierre et son cot