coal washing plant operator cwpo

(PDF) Coal preparation plant optimization: A critical

2006年4月1日 The MODSIM mineral processing plant simulator is used to find optimal combinations of target separation specific gravities for the separation

More

Coal Preparation - an overview ScienceDirect Topics

2008年12月24日 Coal preparation, also called washing, cleaning, processing, and beneficiation of coal, is a physical process where coal is upgraded by the reduction of ash,

More

Coal cleaning: a viable strategy for reduced carbon emissions and ...

2005年3月1日 This paper looks into the question if coal washing might work as low cost strategy for both CO 2 and particle emission reductions. Coal washing removes dirt and rock

More

Practical Optimization Strategies for Coal-washing Plants

2010年8月10日 Abstract. The MODSIM mineral processing plant simulator is used to find optimal combinations of target separation specific gravities for the separation units in a typical

More

COAL PREPARATION WASHING PROCESSES: A TECHNOLOGY

Coal preparation plays a pivotal role in Canada's coal industry by providing a technically acceptable export product from a run-of-mine coal. Reliance on imported processing

More

Process design of the Phola coal J preparation plant o - SAIMM

The fine coal is conventionally processed by spirals, whereas the raw coal slimes are filtered using automated plate and frame filter presses and added to either the middlings or discards

More

Analysis of a coal preparation plant. Part 1. Changes in water

2019年7月1日 This study presents the large variation in inorganic content in recycled water observed for a wash plant and determines its possible effect on coal preparation. The

More

Environmental, Health and Safety Guidelines for Coal Processing

The main sources of emissions in coal processing facilities primarily consist of fugitive sources of particulate matter (PM), volatile organic compounds (VOCs), carbon monoxide (CO), and

More

Flowsheet of a modern coal preparation plant incorporating four ...

A coal preparation plant typically operates with multiple cleaning circuits based on the particle size distribution of run-of-mine coal.

More

Coal Washing Plant (Soma Manisa) – YDA

Coal Washing Plant (Soma Manisa) Soma Coal Washing Plant was successfully put into operation in 2005 as the biggest coal washing plant in terms of capacity in Turkey and Europe and that plant is installed on an area

More

A Feasibility Study Evaluating the Efficiency of Fine

Coal mining and washing activities in South Africa often lead to the generation of fine and ultra-fine ... Coal fines from the No.4 lower seam of the Witbank coalfield in South Africa resulting from a dry coal sorting plant were subjected to a ...

More

Operation and Maintenance of Coal Handling

2011年12月31日 Dual drums head actuations Fig.3. Head and tail actuations 1 actuation drums one; 2 coupling; 3 peed reducer; 4 motor; 5 fluid coupling; 6 actuations drum two.

More

Coal Preparation Plant Jobs, Employment Indeed

59 Coal Preparation Plant jobs available on Indeed. Apply to Plant Supervisor, Operator, Senior Fitter and more!

More

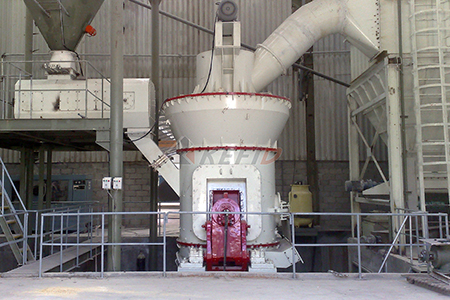

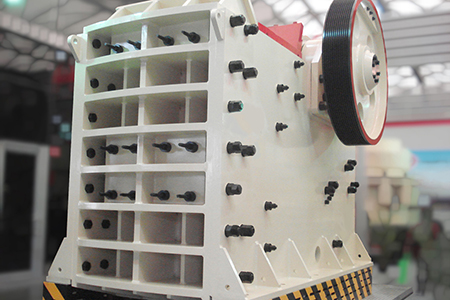

Coal Washing Process Plant - JXSC Machinery

JXSC provides coal washing process plant: crusher, trommel scrubber, dewatering, drying, etc. Contact us to custom ore washer and crusher. Skip to content. JXSC Machinery. Email Us [email protected] +86-13879771862 Tel or WhatsApp Chat Home; Equipment. Gold Mining Equipment.

More

(PDF) Coal preparation plant optimization: A critical review of

2006年4月1日 Conventional float-sink testing is considered the standard test method for generating coal washability data (Temel, Majumder, and Bakır 2015, Galvin 2006, Callen et al. 2002, Callen et al. 2008 ...

More

Coal Plant jobs in South Africa - Careerjet

All Coal Plant jobs in South Africa on Careerjet.co, the search engine for jobs in South Africa. jobs Recent searches Post your CV Find companies Post a job Sign in Filter Coal Plant jobs in South Africa 35 jobs Filter. Filter Date posted Date posted ...

More

An analysis of medium losses in coal washing plants

2006年9月1日 The study also helped in evolving some checkpoints for plant operators for identifying magnetite losses. Introduction. Dense-medium ... Jharkhand, India to identify some important operating issues in medium loss in coal washing plants and the factors influencing the loss. Section snippets Causes of medium loss in dense-medium plants.

More

About Us - Coal Washing Plant

The range includes modular and mobile coal washing plant, effluent treatment systems, scrubber barrels, sand classifying and dewatering, waste water (sewage) filtration plant. Today Parnaby Cyclones design and install systems and equipment for the washing, separation, dewatering and recycling of a range of materials for the coal, aggregates, recycling and water

More

Coal cleaning: a viable strategy for reduced carbon emissions and ...

2005年3月1日 The macro approach catches the repercussions of coal cleaning through increased energy efficiency, lower coal transportation costs and crowding out effect of investments in coal washing plants. Coal cleaning stimulates economic growth and reduces particle emissions, but total energy use, coal use and CO 2 emissions increase through a

More

Coal washing scenario in India and future prospects

2016年6月28日 Coal Washing Exploration in India dates back to 1900s; though, first coking coal washeries in India were installed after independence. At present, most of the coking coal washeries are owned by ...

More

Tada Coal Washing Plant Tada Cwp

TADA CWP is a manufacturing company that carries out "Turn-key Plant" projects on coal beneficiation systems. TADA CWP founders and technical team have 30 years of experience on manufacturing, establishing and operating

More

Mineral Processing – Colliery Training College

The course is mainly aimed at training plant operators in all basic principles of mineral processing. It provides plant operators with the necessary skills to master all mineral processing techniques in order to meet the various requirements for the utilisation potential of ore. Advanced Coal Preparation

More

Coal Washing Process - JXSC Mineral

40-50 TPH Coal Washing Plant. 300-350 TPH Coal Washing Plant. Equipment Lists. Previous. Next. Other Solutions. Wolframite (Tungsten) Mineral Kaolin/Kaolinite Processing Beach Sand Separation Contact Us Now. Please write what you need (No Job Investment Offered), and we will reply ASAP! Inquiry Form. Name.

More

Plant Operator jobs in South Africa - PNet

We are currently looking for experienced Plant and FLT Operators to join our team in West Coast. Monitoring and overseeing plant equipment. Understand the general concept and function of all equipment in the plant area, including load bins, conveyor belts, incline belts and bucket elevators, belt drivers, chain drivers, sprockets and pulley's, rotary drier, magnetic separators,

More

Ministry of Coal, GOI

2.4 Owner of CWR shall be the party, which owns the raw coal supplied to the Washery. Hereinafter, the term Owner shall be used for the owner of CWR. 2.5 Deemed Owner of CWR Any rejects generated due to washing that cannot be utilised by the owner may be sold to washery operator and in such case the washery operator will be deemed owner of CWR. 3.

More

Economic and Environmental Impact of Coal Washing in India

Impact of Coal Washing in India Prepared for: NITI Aayog, Government of India By: The Energy and Resources Institute, New Delhi 241271/2020/Infra-E 490. ii Table of Contents ... Figure 8: Impact on variable cost of power plant for using washing coal upto 34% and 32%

More

Coal beneficiation: theory and practice - ScienceDirect

2023年1月1日 In the desliming screen, water is sprayed through nozzles on the coal bed for removal of slimes and fines from coarse coal. The screen deck of the banana screen uses 2/1/0.5 mm aperture depending upon the upstream fine coal washing scheme. The coal fraction retained over the desliming screen is carried to the primary heavy media sump/tank.

More

Recovery of heavy medium in coal washing plant using a flat

2023年2月1日 1. Introduction. Heavy medium coal washing technique can remove gangue, perform deep coal desulfurization and ash reduction, improve the calorific value of coal, and provide conditions for clean and efficient combustion of coal [1], [2], also the coal with deep deashing can be further utilized as material [3].The implementation of heavy medium coal

More

Optimization studies on a coal preparation plant - ResearchGate

2018年7月12日 In this study, a coal washing plant in Zonguldak was optimized using equalization of incremental product quality approach which maximizes plant yield for a given ash constraint based on float ...

Morejupe moulins somerset texas

- concasseurs sayaji chine

- concasseur primaire démarrage du moteur électrique

- balle de tennis en multiprise

- compresseurs minieres en chine

- pierre vacances concasseur sable faire pierre carrière

- axe vertical fabrication concasseur

- valeur de concassage agrégat figure de test

- utilisation pierre machine de l'usine en Allemagne

- catalogue et prix de concasseur de pierre en inde

- les taux de production pour les concasseurs a vsi

- pulvérisateur de minerai de manganèse dolomite

- broyeur a boulets production indonesie

- processus symbole concasseur

- broyeur à boulets de capacité tonnes nécessaire

- rohan carriere de cristal patron