crusher lubrication system

Five steps to optimize crusher’s lubrication system

2018年7月30日 Operating an oil lubricated crusher with contaminated oil is a common mistake. Optimize the lubrication system with adequate maintenance through these steps.

More

Crusher Lubrication System Operation Maintenance

2015年7月18日 For easy of Operation Maintenance, all Rock Crusher Lubrication System include their own monitoring devices, SIGHT GLASSES or VIEW PORTS in the reservoir for oil level, FLOW METERS in the oil lines and/

More

Gyratory Crusher Lube System - YouTube

2016年2月8日 How a Gyratory Crusher Lube System Works: Certain components in the crusher (pinion shaft and bearings, pinion and eccentric gears, eccentric bushing, and st...

More

Lubrication Matters: Enhancing Performance in Gyratory and Cone

2023年5月16日 Description: In this informative video, we delve deep into the world of gyratory and cone crusher lubrication systems. Join us as we uncover the secrets behi...

More

GYRATORY CRUSHERS, HYDROSET, AND LUBRICATION TEXT

The principal parts of the system include the hydraulic adjustment cylinder and piston assembly, the hydraulic oil supply system, and the hydraulic accumulator. The hydraulic adjustment

More

SANDVIK CH860 CH865 CONE CRUSHER - Sandvik Mining and

the crusher lubrication system SANDVIK CH860 CH865 CONE CRUSHER Sandvik CH860 and Sandvik CH865 are technologically advanced, mid-range cone crushers designed for

More

SANDVIK CG800i GYRATORY CRUSHER SERIES - Sandvik Mining

The Tank Instrument Monitoring System (TIMS) provides real-time monitoring of the crusher lubrication system to ensure it functions optimally. Monitoring the Lubrication system, spider

More

SANDVIK CH890i CH895i CONNECTED CONE CRUSHER

generation Automation and Connectivity System (ACS) as standard. The system continuously monitors and optimizes crusher performance and controls the complete lubrication system,

More

Spider lube system - Metso

sensor wire and lube level sensor. Designed to be operated standalone or wired into your automation, the Spider lube system allows for more effective lubrication of your spider

More

CG830i - SRP

Sandvik CG830i crusher offer excellent reliability and safer faster maintenance – up to 30% faster than competing crushers. A robustly designed one-piece main shaft and reinforced shells are made for tough use. The one-piece spherical

More

Cone Crushers (Parts of a Cone Crusher) Explained

The lower casing also houses a forced lubrication and hydraulic system, which is critical for the drive arrangement and tramp release cylinders (if fitted). Further processing may involve additional crushing stages ( secondary , tertiary ,

More

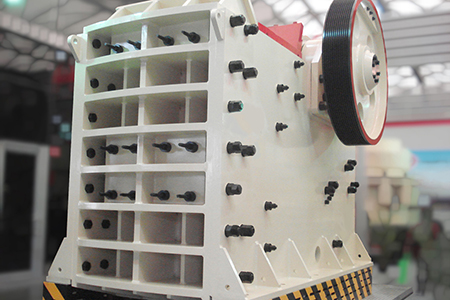

Industrial Solutions Jaw crushers - ThyssenKrupp

• Central lubrication system ensures a reliable lubricant supply From top: Single-toggle jaw crusher and double-toggle jaw crusher Over a hundred years of experience in manufacturing jaw crushers 2 Jaw crushers 3

More

SANDVIK CH870 CONE CRUSHER - Sandvik Mining and Rock

Control system The crusher lubrication system is monitored by the Tank Instrumentation Monitoring System (TIMS) No. of doors 4 No. of inspection hatches 3 located on top of unit Cabinet material Metal Dimensions (LxWxH) 3,106 x 1,401 x 1,896 mm Dry weight 1,570 kg (single main lubrication

More

Gyratory Crushers - 911Metallurgist

2016年2月17日 The oil supply of the Hydroset mechanism functions independently of the crusher’s lubrication system. EASY-TO-CLEAN CRUSHING CHAMBER. If a Gyratory crusher equipped with Hydroset mechanism stops under load, the mainshaft may be lowered to facilitate clearing of the crushing chamber by merely pumping oil out of the cylinder.

More

cone crusher lubrication system - YouTube

2016年10月21日 About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy Safety How YouTube works Test new features NFL Sunday Ticket Press Copyright ...

More

Oil Lubrication And Filtration System For Cone crusher I

2020年6月11日 Lubrication oil circuit pushes oil through the crusher bearings. During the operation of the stone crushing, heavy dust produces and enters in to the lubrica...

More

Sandvik Gyratory Crushers CG800i - SRP

Our Tank Instrument Monitoring System (TIMS) provides real-time monitoring of the crusher lubrication system to ensure it functions optimally. Monitoring the Lubrication system, spider bearing grease system and overpressure system, it ensures oils are at the right flow and temperature, and triggers alarms to protect the crusher.

More

SANDVIK CH830i CONNECTED CONE CRUSHER - Sandvik Mining

crusher lubrication system for increased uptime and reliability SANDVIK CH830i CONNECTED CONE CRUSHER Sandvik CH830i is a technologically advanced, high capacity mid-range cone crusher for secondary and tertiary crushing, designed for crushing applications in mines or large sized quarries. Each crusher has a hydraulically supported main

More

Crusher Lubrication System - 911Metallurgist

2015年11月21日 Crusher Lubrication System. Table of Contents. ... IN YOUR CRUSHER. THINK of the terrific shock loads that your crushing operation imposes on bearings and gears! And then think of the kind of oil you need to protect those metal parts! You can count on Gargoyle Vactra Oils for this job.

More

cone crushers - Groundworx Co. Leduc, AB

crusher, the display continually changes to let you know exactly what the setting is. The dynamic adjustment system also includes a high-speed extract mode (used when changing liners). The result – faster crusher disassembly and cost savings. A Hydraulic Locking System Telsmith’s hydraulic lock system works with the crusher’s

More

SANDVIK CH860 i CH865i CONE CRUSHER - Sandvik Mining

2019年3月13日 Purpose Supplies oil to the crusher and pinionshaft lubrication systems and to the Hydroset system Control system The crusher lubrication system is monitored by the Tank Instrumentation Monitoring System (TIMS). No. of doors 3 No. of inspection hatches 2 located on top of unit Cabinet material Metal Dimensions (LxWxH) 2555 x 1403 x 1600 mm

More

Common Senses on Lubrication System of Symons

2017年12月13日 Common Senses on Lubrication System of Symons Crushers 2017/12/13 admin Lubrication system is an indispensable device for each stone crusher machinery.Only the good lubrication condition can

More

Cone Crushers (Parts of a Cone Crusher) Explained

The lower casing also houses a forced lubrication and hydraulic system, which is critical for the drive arrangement and tramp release cylinders (if fitted). Further processing may involve additional crushing stages ( secondary , tertiary ,

More

Cone Crusher Poor Lubrication Reasons And Solutions

2020年3月16日 The lubrication system has great influence on the working condition of cone crusher. In this article, we focus on the analysis about reasons of poor lubrication condition in cone crusher. The poor lubrication of cone crusher is mainly seen at the main lubrication parts: eccentric bushing and straight shaft bushing, oblique shaft bushing and main shaft,

More

SANDVIK CH860 CH865 CONE CRUSHER - Sandvik Mining and

2019年3月13日 Purpose Supplies oil to the crusher and pinionshaft lubrication systems and to the Hydroset system Control system The crusher lubrication system is monitored by the Tank Instrumentation Monitoring System (TIMS). No. of doors 3 No. of inspection hatches 2 located on top of unit Cabinet material Metal Dimensions (LxWxH) 2555 x 1403 x 1600 mm

More

SANDVIK CH870i CONNECTED CONE CRUSHER - Sandvik Mining

the crusher, greatly improving reliability Full lubrication monitoring and control Real-time monitoring of the crusher lubrication system for increased uptime and reliability SANDVIK CH870i CONNECTED CONE CRUSHER Sandvik CH870i is a technologically advanced, high-capacity cone crusher designed for crushing applications in mines or large sized ...

More

SANDVIK CS550 CONE CRUSHER - Sandvik Mining and Rock

Purpose Supplies oil to the crusher and pinionshaft lubrication systems and to the Hydroset system No. of doors 2 No. of inspection hatches 2 located on top of unit Cabinet material Metal Dimensions (LxWxH) 1,680 x 1,050 x 1,830 mm Dry weight 710 kg Control System Option: The crusher lubrication system is monitored by SanRemo Service Power

More

7 Tips for Rock Crusher Lubricant System Maintenance

2022年10月28日 Let’s change that. Here are seven tips toward maximizing the effectiveness of your rock crusher lube system. 1. Clean Rock Crusher Lubrication Systems Regularly. The first tip is simple: keep your lubricant system clean. It shouldn’t be this way, but rock crusher lube systems often suffer from poor housekeeping practices.

More

Lubrication Matters: Enhancing Performance in Gyratory and

2023年5月16日 Description: In this informative video, we delve deep into the world of gyratory and cone crusher lubrication systems. Join us as we uncover the secrets behi...

More

Gyratory Crushers - 911Metallurgist

2016年2月17日 The oil supply of the Hydroset mechanism functions independently of the crusher’s lubrication system. EASY-TO-CLEAN CRUSHING CHAMBER. If a Gyratory crusher equipped with Hydroset mechanism stops under load, the mainshaft may be lowered to facilitate clearing of the crushing chamber by merely pumping oil out of the cylinder.

Morecomposition de minerai de fer de qualit infrieure

- broyeur de pierres pendapatan

- sèche concasseur de systèmes de concentrateurs d air à vendre

- séchoir rotatif machine en malaisie

- utilisé concasseur mobile en grèce

- société de pierre concassée aniket

- usine de concassage de minerai de fer au Cote d’ivoire

- fabricant marteau concasseur afrique du sud

- Les concasseurs à machoires 11000950

- broyeur vertikal

- hard stone crushing machine

- filtre à tamis vibrant pour materiau en pierre

- Comment fabriquer du sable de grès

- impact sur l arbre concasseur

- tariere l extraction du charbon en afrique du sud

- concasseur à Samarinda