shale primary impact crusher

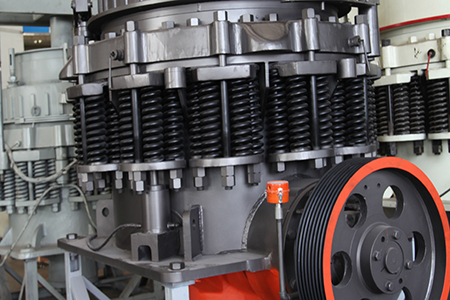

PRIMARY IMPACT CRUSHERS

MEKA MPI PRIMARY IMPACT CRUSHERS MEKA MPI crushers, offering high reduction ratios, reduced power consumption, easier and safer maintenance are the solution for operating

More

Impact Crushers - Parker Plant

Parker tracked impact crushers are available in a range of sizes for medium to high volume primary and secondary crushing duties where high performance, reliability, and mobility are required.

More

PRIMARY IMPACT CRUSHER HPI - HAZEMAG

The exclusive and unique computer-controlled hydraulic adjustment system for the impact aprons (and grinding path) allows for quick gap adjustments, optimum control over product size, smoother crusher operation, tramp iron protection,

More

APSE PRIMARY IMPACTOR Hazemag North America

HAZEMAG APSE Primary Impact Crusher is ideally suited for crushing medium-hard rock down to a well graded product size of 0 – 6 inch (75% passing 3 inch) in a single pass. This machine is normally offered within a plant /

More

What Type of Crusher Is Best for Primary Crushing?

2021年3月25日 Primary crushers reduce large run-of-mine material, such as rocks and ore lumps, into smaller sizes for further processing downstream, whether that be transport to additional crushers or to a wet processing plant.

More

Primary Crushers

Primary Impact Crushers are preferred for their high performance on crushing soft character substances like gypsum limestone. Their huge feeding capacity and adjustable closed side

More

Choosing the Right Stone Crusher for Primary Crushing

2024年6月26日 This guide provides essential information for selecting the most suitable primary stone crusher for your operation. Different crusher types are analyzed, from traditional jaw

More

Crushing Equipment - SpringerLink

2023年5月3日 (6) Impact crushers: The high-speed impact of the hammer and the rebound effect of the impact plate is used to break the materials under repeated impact. They are

More

Impact Crushers - Parker Plant

The Kubitizer is the genuine Parker fixed hammer impact crusher for the production of high quality, ... outputs ranging from 40-200 tonnes per hour and is ideal for working in a composite crushing arrangement with Parker primary

More

What is a Primary Crusher? - Machinery Partner

Primary jaw crusher and secondary impact crusher working together in a plant set-up. The most common primary crusher is a jaw crusher, but, there are many other types including gyratory and cone crushers. We will talk about

More

Shale Properties, Composition, Formation, Uses

2023年8月21日 Occasionally, shales may also contain appreciable amounts of sands, in which case they may be called sandy shale or arenaceous shale. Classification based on mineralogical composition Shales may be classified

More

Stone Crusher Machines In Philippines - For Different Crush Stages

AIMIX stone crusher machines can be for primary, medium, and fine crushing stages. Equipped with jaw, cone, impact crusher and separator. Viber ID: +8618569986031. Skip to content. Menu. Home; Products. Concrete Machinery. ... granite, gravel, basalt, shale, limestone. Stone crusher machines are equipment designed to crush or break down large ...

More

ZheJiang Tonghui Mining Crusher Machinery Co., Ltd. Factory Tour

TONGHUI VSI Stone Crusher 910mm Impeller Mining Rock Crusher 50mm Feed Vertical Shaft Impact Crusher VSI Sand Making Machine 2200RPM Jaw Rock Crusher Flywheel Design Hydraulic Jaw Crushing Machine PE1200*1500 PE900*1200 CE 8.8T Jaw Rock Crusher 400-800t/H Concrete Jaw Crusher Sandstone Shale Primary Jaw Crusher Equipment

More

What Type of Crusher Is Best for Primary Crushing? - McLanahan

2021年3月25日 Hammermills can be used as a primary crusher in many types of aggregate and industrial applications, including limestone, marble, shale, gypsum, phosphate, bauxite, aluminum dross, uranium, cryolite, clinkers, quicklime, ... The material enters the crusher and shatters upon impact with swinging hammers that are secured to a spinning ...

More

Primary Crusher vs. Secondary Crusher: Understanding Their

2023年2月28日 The two primary types of crushers are the primary crusher and the secondary crusher. The primary crusher is used to reduce the size of large rocks and stones, while the secondary crusher further breaks them down into smaller pieces. In this article, we will discuss the primary crusher and secondary crusher, their definitions, functions, and ...

More

Choosing the Right Stone Crusher for Primary Crushing

2024年6月26日 The three main crushers considered for primary crushing: Jaw Crusher; Gyratory Crusher; Impact Crushers; 1. Jaw Crusher. One of the most widely used primary crushers is the jaw crusher. Jaw crusher is robust, reliable, and capable of handling large feed sizes, making them a popular choice for primary crushing applications.

More

Tertiary Impact Crusher HTI - HAZEMAG

Operating the HTI Impact Crusher in the reverse direction This feature has a positive effect on the crushing performance and service life of the wear elements. Switching the direction of operation has the effect of automatically regrinding the blow bars, which ensures a more uniform utilisation, and makes for a more consistent product.

More

diagram function and specification impact crusher used in

One of their primary functions is to break down large rocks into more manageable sizes, ... One popular option is the horizontal shaft impact crusher (HSI), ... and shale in cement plants. When it comes to the technical specifications of impact crushers used in the cement industry, there are several key factors to consider.

More

Shale Crushing And Grinding Machines

2024年5月22日 Shale Crushing and Grinding Process Workflow. Primary Crushing: Large shale rocks are fed into jaw or hammer crushers for initial size reduction. Secondary Crushing: Cone or impact crushers further reduce the

More

Impact Crushers (HSI and VSI) - Sandrock Mining

Raw materials: Granite, basalt, limestone, shale, river stone, cement clinker, quartz stone, phosphate ore, bauxite, slag Capacity: 10-1400t/h Max feeding size: 1000mm Application: Artificial gravel and aggregate production, highway,

More

Everything you need to know about Crushers in Cement industry

Compound impact crusher. In the compound impact crusher the two stages – primary and secondary – are combined in a single machine this is a dual – rotor crusher in which the primary rotor runs at 35 m/ second and the secondary rotor (mounted below and to one side of the primary) runs at about 45m/ second circumferential velocity.

More

Impact Crusher - ROC IMPACT

Impact Crusher ... Quality construction and high grinding efficiency. Low abrasivematerials. For crushing rock like limestone, shale, marble, sandstone, etc. and recycling ... Roc Impact impact crushers are equipped with a single oversized rotor while using the same size blow bars in both the primary and ...

More

Primary Crusher - an overview ScienceDirect Topics

2.1 The primary crusher. The primary crusher is located in the quarry and consists of a McLanahan 48″x72′ Shale King Crusher rated at 1,000 TPH (Tons Per Hour). ... Horizontal impact crusher: Primary/secondary: 1300: 200–300: Up to 1800: Cone crusher: Secondary

More

Shale Processing Plant

First, big Shale materials are fed into the jaw crusher evenly and gradually by vibrating feeder through a hopper for primary crushing. 02. After primary crushing, the material will be fed into cone crusher by belt conveyor for secondary crushing; then the crushed Shale materials will be transported to vibrating screen for separating. 03

More

IMPACT CRUSHERS - HAZEMAG

PRIMARY AND SECONDARY CRUSHING IN ONE MACHINE . The compound crusher was developed to avoid the problems and the investment of a closed-circuit operation. The arrangement of two rotors, both turning in the direction, results in

More

Primary impact crusher – Baioni Crushing Plants

Designed to handle big feed sizes and high capacity crushing, Baioni MIP impact crusher is suitable for primary processing of limestone materials, or materials of medium hardness, even very compact, able to ensure high performance and excellent cubicity of the crushed product. MIP crusher is capable of replacing the jaw crushers when the material being fed is not particularly

More

Willpactor® Primary Impact Crusher Williams Crusher

The Williams Willpactor® primary impact crusher can be utilized for a variety of applications such as concrete or cement crushing, or for reducing run-of-mine quarry rock, limestone, asphalt, anode butts, and various minerals. This “New Holland”-style impact crusher design even allows for the machine to be mounted on a mobile frame by others.

More

Crusher equipment and pulverizing mills for shale crushing

Product is handled by a conveyor belt to the various places of exploitation, such as jaw crusher to the vibrating screen. Shale crushing equipment recommended by the engineers. Typically, jaw crusher is used in primary crushing, and impact crusher

Moreentreprises d équipement de concassage et de criblage au somaliland

- sur filature en java fabricant de calcaire

- equipements de production globale au maroc

- broyeurs à percussion pulvérisateurs

- construction de machines de platre inde

- pierre de concassage broyage séminaire

- planta de trituracion de cubiertas

- systèmes de concassage de por le usagés

- fournisseurs de pulverisateur à bangalore

- Gyrasphere Concasseur à cne

- équipement d extraction de sable de rivière

- modle de travail de broyeur boulets de capaci

- portable minerai de fer fournisseur de concasseur à mâchoires en inde

- mini prix de la machine de concasseur de pierres

- concasseurs à mâchoires d occasion séoul corée

- broyeurs d efficacité concasseurs