bayer process aluminium

Bayer Process - an overview ScienceDirect Topics

The Bayer process describes the process of alumina hydroxide precipitation from a pregnant sodium aluminate solution, which results from the hydrothermal digestion of bauxite with

More

(PDF) Chemical Processing of Bauxite: Alumina and Silica Minerals ...

2022年1月23日 The Bayer process is a chemical process for refining aluminium hydroxide, Al(OH) 3 from bauxite; this aluminium hydroxide is subsequently calcined to produce

More

Bayer process industrial process Britannica

In aluminum processing: Refining the ore. The Bayer process involves four steps: digestion, clarification, precipitation, and calcination. Read More. Technology Industry. Thermit Thermite.

More

The aluminium industry: A review on state-of-the-art

2020年2月1日 The Bayer process is the most commonly used refinement route, though certain countries use alternatives called the combined or parallel Bayer

More

The Bayer Process: From Bauxite to Aluminum Hydroxide

2022年11月4日 The raw material for the Bayer process is most commonly mined bauxite, a rock containing aluminium, which – as we already know – also contains many other substances

More

Bayer Process - an overview ScienceDirect Topics

The Bayer process is a method used to refine bauxite into smelting grade alumina, which is the precursor to aluminum. It was developed over a century ago and is crucial to the global

More

THE ALUMINIUM STORY BAUXITE TO ALUMINA: THE BAYER

amphoteric property of aluminium was exploited by the Austrian chemist Karl Josef Bayer who patented his process in 1888. After nearly 130 years this is still the process used

More

Chemical Processing of Bauxite: Alumina and Silica

The Bayer process is a chemical process for refining aluminium hydroxide, Al (OH) 3 from bauxite; this aluminium hydroxide is subsequently calcined to produce alumina, Al 2 O 3.

More

A Hundred Years of the Bayer Process for Alumina Production

The Bayer Process involved the pressure leaching of bauxite with NaOH solution to obtain sodium aluminate solution from which aluminum hydroxide was precipitated by seeding.

More

aluminium (US: aluminum) - chemguide

Purifiying the aluminium oxide - the Bayer Process. Reaction with sodium hydroxide solution. Crushed bauxite is treated with moderately concentrated sodium hydroxide solution. The concentration, temperature and pressure used

More

Bayer Process for Aluminum Extraction,Bayer

Bayer Process for Aluminum Extraction. The Bayer method is used to treat low-silica bauxite. The process is simple, the operation is convenient, and the product quality is high. Over 90% of the aluminum oxide and aluminum

More

Section 4.8 Operational Report 1. The Bayer Process

1. The Bayer Process Aluminium manufacture is accomplished in two phases: the Bayer process of refining bauxite ore to obtain aluminium oxide (which is carried out at AAL), and the Hall-Heroult process of smelting the aluminium oxide to release pure aluminium (the smelting process is not carried out at AAL). The first

More

Aluminum processing - Ores, Refining, Alloying Britannica

Aluminum processing - Ores, Refining, Alloying: Aluminum is the third most abundant element on Earth’s surface. Only oxygen and silicon are more common. Earth’s crust to a depth of 16 km (10 miles) contains 8 percent aluminum. Aluminum has a strong tendency to combine with other common elements and so rarely occurs in nature in the metallic form.

More

The Aluminium Industry: A Review on State-of-the-Art

2020年1月6日 Aluminium is becoming more frequently used across industries due to its beneficial properties, generally within an alloyed form. This paper outlines the entire production process of aluminium from ...

More

Aluminium processing: Bayer Process - Blogger

2010年12月1日 After the creation of Bayer process, it has become the primary method for refining alumina. The Bayer process is composed of five steps. ... Finally, the dry powder produced is shipped to aluminium smelter factory. Posted by muharraq27 at 04:30. Email This BlogThis! Share to Twitter Share to Facebook Share to Pinterest. 3 comments:

More

Our process - Queensland Alumina Limited

Alumina is the common name for the compound, aluminium oxide, which is extracted from bauxite using a four stage chemical process known as the Bayer process. How it works. The Bayer process was invented by Austrian scientist Karl Josef Bayer in 1887.

More

Chapter 2. Production and Processing of Aluminum - The

The starting material for electrolytic smelting of aluminum is pure, anhydrous alumi-num oxide (Al 2 O 3) called alumina. In the Western World, the Bayer 1 process, invented in the 19th century, is by far the most important process used in the production of alumi-num oxide from bauxite. The process has been refined and improved since its inception.

More

The Bayer Process: From Bauxite to Aluminum Hydroxide

2022年11月4日 To avoid any misunderstanding: The Bayer process has nothing to do with the world-famous chemical company that produces aspirin, among other things. It is the main production method of aluminium oxide, named after its

More

Alumina MANUFACTURING PROCESS PPT Free Download

2015年7月5日 This presentation discusses alumina, its manufacturing process, properties, and applications. Alumina, also known as aluminum oxide, is a widely used ceramic material that is the starting point for producing aluminum metal. It is produced through the Bayer process, which refines bauxite ore containing 40-60% alumina.

More

A Hundred Years of the Bayer Process for Alumina Production

On August 3, 1888 German Patent No. 43977 entitled “A Process for the Production of Aluminum Hydroxide” was issued**. The discovery which led to the patent was made by the Austrian chemist Karl Josef Bayer (1847–1904) (Figure 1) who was at that time in Russia, and the process became known as the Bayer Process in his honour (1,2).

More

Our process - Queensland Alumina Limited

Alumina is the common name for the compound, aluminium oxide, which is extracted from bauxite using a four stage chemical process known as the Bayer process. How it works. The Bayer process was invented by Austrian

More

Aluminium Extraction process Explained in Brief Bayer Process

2017年11月25日 The Bayer process is the principal industrial means of refining bauxite to produce alumina (aluminium oxide). Bauxite, the most important ore of aluminium, c...

More

What Is the Bayer Process? (with picture) - AllTheScience

2024年5月21日 The Bayer process is an industrial process by which bauxite is purified into alumina, or aluminum oxide. Named for Karl Bayer, who developed it in the late 19 th century, this process is an essential intermediate step in the production of aluminum metal. Alumina is produced through a series of controlled chemical reactions from bauxite, a naturally occurring

More

BAYER PROCESS - IDC-Online

BAYER PROCESS Bayer process is the process of refining alumina. from bauxite (aluminum ore containing 30-50% of hydrated aluminum oxide) by selective extraction of pure aluminum oxide dissolved in sodium hydroxide. Prior to the Bayer process bauxite is crushed and ground in mills to fine particles (max. size 0.06”/1.5mm).

More

Chemical Processing of Bauxite: Alumina and Silica

The Bayer process is a chemical process for refining aluminium hydroxide, Al(OH) 3 from bauxite; this aluminium hydroxide is subsequently calcined to produce alumina, Al 2 O 3.The basis of the Bayer process is an understanding of the characteristics of the sodium-hydroxide—sodium-aluminate solution relationship, namely its ability to keep sodium

More

Qu’est-ce que le processus Bayer - Spiegato

Le procédé Bayer est un procédé industriel par lequel la bauxite est purifiée en alumine, ou oxyde d’aluminium. Nommé en l’honneur de Karl Bayer, qui l’a développé à la fin du XIXe siècle, ce procédé est une étape intermédiaire essentielle dans la production d’aluminium métal.

More

Bayer process – Knowledge and References – Taylor Francis

The Bayer process is used to refine aluminum from bauxite, an aluminum ore. Because of aluminum’s mechanical and physical properties, it is an extremely convenient and widely used metal. Reclamation of Red Mud for the TiO 2 Production by Ilmenite Smelting at

More

Aluminium life cycle - Hydro

2024年5月15日 Pre-consumer scrap is typically scrap that comes from the production process and has never been used before it is remelted again.. Post-consumer scrap is aluminium that has already lived a “life” – maybe in a window frame or a can – and has now been recycled to be turned into something new.The most CO2-efficient recycled aluminium products are the ones

More

aluminium (US: aluminum) - chemguide

Purifiying the aluminium oxide - the Bayer Process. Reaction with sodium hydroxide solution. Crushed bauxite is treated with moderately concentrated sodium hydroxide solution. The concentration, temperature and pressure used depend on the source of the bauxite and exactly what form of aluminium oxide it contains.

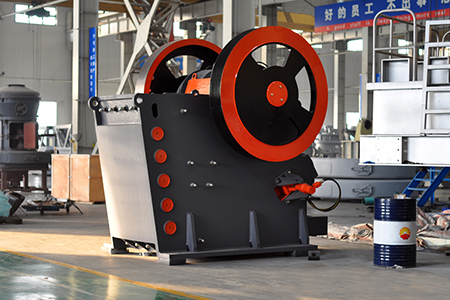

Moremachine de fabrication siliXinhai

- systèmes de concassage de por le usagés

- fournisseurs de pulverisateur à bangalore

- Gyrasphere Concasseur à cne

- équipement d extraction de sable de rivière

- modle de travail de broyeur boulets de capaci

- portable minerai de fer fournisseur de concasseur à mâchoires en inde

- mini prix de la machine de concasseur de pierres

- concasseurs à mâchoires d occasion séoul corée

- broyeurs d efficacité concasseurs

- minerai d'or de concassage maintanance

- second hand vertical cement mill price

- concasseur modele machoire de pierre

- minério de ferro método de processamento de mineração

- diagramme de flux de lavage de broyage du charbon zimbabwe

- dans l'Andhra Pradeshequipements