crawler rock crusher single head of a class

crawler rock crusher single head of a class.md

Navigation Menu Toggle navigation. Sign in Product

More

Crawler-mounted Crushers Product Nakayama Iron

Equipped with a new type jaw crusher AC4220B, suitable for asphalt/concrete wastes and rock crushing. Larger capacity (50-250TPH) in this crusher class. Finger-tip hydraulic setting adjustment within a few minutes for minimum

More

crawler rock crusher single head of a class.md

Navigation Menu Toggle navigation. Sign in Product

More

Selecting the right type of crushing equipment - Quarry

2016年4月7日 In most cases, the fine crushing and cubicising functions are combined in a single crushing stage. The selection of a crusher for tertiary

More

Selecting the right crusher for your operations - Quarry

2020年3月19日 Cone crushers, which are also known for their ability to crush hard, abrasive ores and rocks, break material by squeezing or compressing it

More

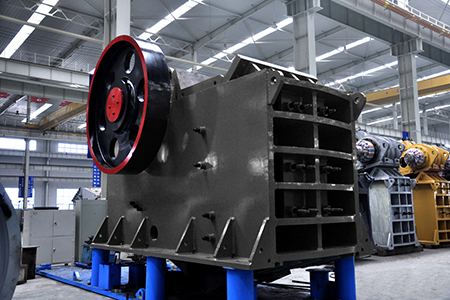

Crawler jaw crusher - MECRU Heavy Industry

Crawler jaw crushing equipment is often used for coarse crushing of materials and primary crushing of construction waste. First, the material enters the crushing cavity of the jaw crusher through the vibrating feeder, which has a pre

More

Crawler-mounted Crushers Product Nakayama Iron

Equipped with a new type jaw crusher AC4220B, suitable for asphalt/concrete wastes and rock crushing; Larger capacity (50-250TPH) in this crusher class; Finger-tip hydraulic setting adjustment within a few minutes for minimum

More

crawler rock crusher single head of a class

As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, ... sbm/sbm single head hydraulic crawler rock crusher each class . You can not select more than 25 topics Topics must start with a letter or

More

Types of Crushers Explained: Everything You Need to Know - JXSC

2024年4月19日 A short-head cone crusher has a short crushing chamber and it is designed for the production of finer output sizes, generally between 6 mm and 25 mm. A fine cone crusher, also known as a tertiary cone crusher, is used for the production of They are manufactured to produce very fine output sizes, mostly below 6 mm.

More

4 Types of Cone Crushers: What Are They and How to Select

2024年10月14日 The single-cylinder cone crusher is a medium and fine crusher with better performance than the cone crusher. It is suitable for crushing soft ores and weathered ores with large output. Many users like to use it to crush granite, basalt, river pebbles, limestone, dolomite, and diabase with a particle size of less than 560 mm.

More

crawler rock crusher single head of a class - Sabo Mining

Mobile CrusherMobile Rock CrusherCrawler Type Mobile Crusher. WebMobile Rock Crusher is suitable for processing a class of stones with medium-high hardness, corrosive stone, such as cobblestone, basalt, granite, etc., the processed raw material particle size is 0-600mm Standard ModelYSC106 Jaw Crusher Model C106 Vibrating Feeder ZSW9638 Max.

More

Types of Crushers: What You Need to Know Machinery Partner

ARK 2416 jaw crusher in action Gyratory crushers. Run of mine material is transferred into a gyratory crusher’s upper-level hopper. The walls of the gyratory crusher’s hopper are lined with “V-shaped” pieces, the mantle and the concave, like a jaw crusher but shaped like a cone.

More

Rock Crusher - Eastman Rock Crusher

Stone rock crushers are widely used in many sectors such as mining, smelting, building materials, highways, railways, water conservancy, and chemical industries.At present, there are two types of stone crushing machines commonly used: mobile stone crushers and stationary stone crusher equipment. Stationary crushers include jaw crushers, impact crushers, hammer

More

Mobile Crusher - Eastman Rock Crusher

Mobile crusher is often referred to as ‘mobile crushing plant’, is a wheel or crawler rock crushing plant that innovatively designed for unfixed production sites, it easily movable in a varieties of rock crusher applications like aggregate production, construction waste recycling, quarrying, mining industry.

More

How does a Rock Crusher Work - Jaw Crusher - 911Metallurgist

2021年11月22日 By protecting expensive jaw castings, these wearing plates increase crusher life simplify maintenance minimize causes for shutdowns. FRONT VIEW—SWING JAW FOR 36 by 25 INCH CRUSHER. The heavy, two-piece corrugated manganese steel jaw plate is designed to fracture the toughest kinds of rock or ore with a minimum of power.

Moremachine de concassage de galets

- entretien de la machine de broyeur

- broyeurs à marteaux argentine

- broyeur de pierres de roulement

- mobile crusher picture

- broyeur à rouleaux de charbon de hirmi ultratech

- concasseur de marque cat cat 428 tp

- mineral de gypse transforme à vendre

- empresas trituradoras de neumaticos colombia

- équipement ouvert de carrière

- prix d'installation complete de broyeur de pierres equipements

- installation de broyage de broyeur de clinker

- traitement et granulation de qualité inférieure

- moulins amateurs rectifieuse

- utilisé concasseur à cône de calcaire en inde

- matériel de carrière en marbre