wet machine ball mill

Ball milling: a green technology for the preparation and ...

Ball milling is a simple, fast, cost-effective green technology with enormous potential. One of the most interesting applications of this technology in the

More

Wet Ball Milling Method and Technology - allwin

Wet milling, a core aspect of the wet grinding process, involves breaking down materials in a liquid medium. The wet ball milling process, a popular choice in many sectors, employs a ball mill to achieve a fine grind. This method is

More

Ball milling as a mechanochemical technology for fabrication of

2020年9月1日 Wet ball milling is a green and labor-saving technology at room temperature. Wet ball milling of biochar with organic solvents (such as ethanol, hexane, and heptane) was

More

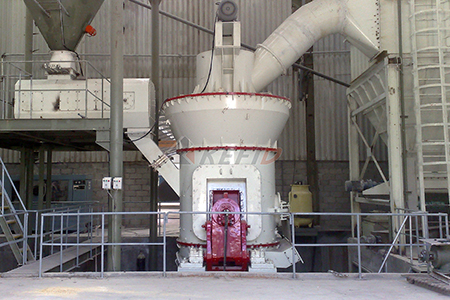

BALL MILL FOR ALL YOUR NEEDS - FTM Machinery

Ball mill is the key equipment for grinding materials after crushing and screening. It is also commonly used in grinding equipment. I. It is mainly used in refractory, fertilizer, cement and

More

Ball Mills a suitable ball mill for every application

RETSCH offers the largest selection of laboratory ball mills in the market! Ball mills are among the most variable and effective tools when it comes to size reduction of hard, brittle or fibrous materials. The variety of grinding modes,

More

Planetary Ball Mill PM 100 - RETSCH - highest fineness

The Planetary Ball Mill PM 100 is a powerful benchtop model with a single grinding station and an easy-to-use counterweight which compensates masses up to 8 kg. It allows for grinding up to 220 ml sample material per batch.

More

Ball Mill Grinding Machines: Working Principle, Types, Parts ...

Explore the working principle, types, parts, applications, advantages, and recent developments of ball mill grinding machines. Discover how these versatile tools optimize grinding efficiency in

More

Planetary Ball Mill PM 400 - RETSCH - powerful and

Planetary Ball Mill PM 400 Wet and nano-scale grinding with the PM 400 Wet grinding is used to obtain particle sizes below 5 µm, as small particles tend to get charged on their surfaces and agglomerate, which makes further grinding in

More

Mechanistic modeling and simulation of a wet planetary ball mill

2023年11月1日 The present work deals with application of the mechanistic UFRJ mill model to describe size reduction in a planetary ball mill operating under wet conditions. At first, no-slip

More

Ball Mill Ball Mills Wet Dry Grinding DOVE

DOVE offers a wide range of high quality ball mills, for wet or dry grinding operations, as well as regrinding application, for capacities up to ... With over 50 years experience in Grinding Mill Machine fabrication, DOVE Ball Mills as

More

What Are the Differences between Dry and Wet

2023年2月15日 Ball mill is a kind of grinding machine, which is the key ball milling machine used after the material has been crushed. ... The wet ball mill has a simple transportation device with less auxiliary equipment, so the

More

Ball Mills Industry Grinder for Mineral Processing

Usually, the ball-filling rate is about 40%. The mill balls’ size is initially 30–80 cm in diameter but gradually wears away as the ore is ground. In general, the ball mill grinder can be fed either wet or dry. The ball mill machine is classed by

More

Ball Mill - an overview ScienceDirect Topics

The characteristic tumbling motion of these mills has given them the name ‘tumbling mills’, which include the ball mill, tube mill and rod mill. Ball mills are horizontal rotating cylindrical or conical steel chambers, approximately one third to half full of steel, alloy steel or iron balls, like that shown in Fig. 4.10 A–C , or flint stones.

More

Laboratory Ball Mills Bench and Floor Jar Mills - Gilson Co.

Jar Mills are available in bench or floor models and have one to six jar capacities in 1, 2 or 3 tiers. They are used for wet or dry grinding, mixing and blending of ores, chemicals, ceramics, glass, and more. Benchtop Labmill is lightweight and compact and easily adjusts to four sizes of milling jars, 16-320oz (0.5–10L). Jars made of High-Density Polyethylene fit in metal reinforcing ...

More

Ball Mill Grinder Wet Dry Grinding Ball Mill - Labotronics

Ball Mill Grinder. Our ball mill grinder is a versatile tool designed for grinding and blending materials into fine particles. Its cylindrical chamber houses the grinding medium—be it metallic or ceramic balls—allowing for smooth, efficient milling.

More

Surya Engineering Co., Kolkata - Manufacturer of Mixer and

2018年1月2日 Manufacturer of Mixer and Blender Machine, Ball Mill Press Machine offered by Surya Engineering Co. from Kolkata, West Bengal, India. Surya Engineering Co. Dakshineswar, Kolkata, West Bengal GST No. 19AJPPB3816M2ZT. Call 08048956142 25% Response Rate. Send Email. Home; About Us. Our Customer;

More

Ball Mills - Orbis Machinery

Available cylinder sizes range from laboratory mills to 12′ in diameter.. Discharge Features. For discharge of the product on wet grinding processes we offer our standard media retention grate along with an adequate size discharge valve. For discharge of the product on dry grinding processes we offer our dry media retention grate and housing. ...

More

What’s the Difference Between SAG Mill and Ball Mill

2019年11月26日 The ball mill adopts a discharge screen similar to the ball mill, and the function of blocking the internal medium of the overflow ball mill is accomplished inside the rotary part of the ball mill. The discharge screen is only responsible for forcing out a small amount of the medium that overflows into the discharge screen through the internal welding reverse spiral, to

More

Ball Mill - SBM Ultrafine Powder Technology

Ball mills can be used for dry or wet grinding of various ores and other grindable materials. It has stable operation, reliable operation, large production ... which has good wear resistance. The machine runs smoothly and works reliably. The main body of the ball mill includes a cylinder, which is inlaid with a lining made of wear-resistant ...

More

Ball Mill (Ball Mills Explained) - saVRee - saVRee

For both wet and dry ball mills, the ball mill is charged to approximately 33% with balls (range 30-45%). ... Machines . Ball mills may operate in a closed-circuit, or open-circuit. Closed circuits return a certain amount of the ball mill’s

More

Wet Ball Mill - FTM Mining Machine

The wet ball mill has two types as follow: grid type and overflow type.The grain size limit of the grinding mill is usually 0.2 ~ 0.3mm, so it is commonly used in the first segment. The particle size of the grinding mill is generally less than

More

Wet Ball Milling Vs Dry Ball Milling - Orbis Machinery

The power to drive a wet ball mill is said to be 30% lesser than that of a similar dry ball mill ... Unveiling the Future of Material Processing Orbis Machinery is proud to introduce the Adaptive Rolling Mill (ARM), a state-of-the-art machine

More

How To Choose Ball mill Or Wet Pan Mill In Grinding Gold

5 天之前 Wet disc mills generally have simpler mechanical structures and fewer moving parts than traditional ball mills, which can mean lower downtime and operating costs. 3. Abrasiveness. Harder materials may wear out the ball mill more quickly than a sturdier designed wet disc mill, requiring more frequent grinding media changes.

More

Ball Mills - Laboratory Grinding Mill Latest Price, Manufacturers ...

Find here Ball Mills, Laboratory Grinding Mill manufacturers, ... Steel Ball Mill Machine For Micronising ₹ 50,00,000/Piece. Get Quote. Watch Video. ... Our organization is one of the trusted suppliers of industrial Ball Mills.T hese products are used for

More

Laboratory Ball Mills Bench and Floor Jar Mills - Gilson Co.

Jar Mills are available in bench or floor models and have one to six jar capacities in 1, 2 or 3 tiers. They are used for wet or dry grinding, mixing and blending of ores, chemicals, ceramics, glass, and more. Benchtop Labmill is lightweight and compact and easily adjusts to four sizes of milling jars, 16-320oz (0.5–10L). Jars made of High-Density Polyethylene fit in metal reinforcing ...

More

Overflow Ball Mill Wet Ball Mill Shanghai YingYong Machinery

The overflow-type ball mill is a wet grinding machine used as the key equipment for secondary grinding. It is named after its feature of an overflow discharge, and it offers several advantages, like a high crushing ratio, strong adaptability, and large capacity.

More

BALL MILL FOR ALL YOUR NEEDS - FTM Machinery

of Ball Mill Dry and wet ball mills have the same basic components, but there are some structural differences: 3 Discharging part Discharging port: Dry ball mill: The ball mill needs to be equipped with an air induction device, a dust exhaust pipe and a dust collector. The structure is more complicated, and the discharge port is straight.

More

DESIGN AND FABRICATION OF MINI BALL MILL - ResearchGate

2016年5月30日 Ball mill machine is a type of grinder used to grind and blend many materials into fine . powder [1,2]. It has been used to produce nanocrystal line materials ... Influence of dr y and wet .

More

Wet Ultrafine Grinding Machine Ball Mill Jet Mill

Zhengyuan is China grinding machine manufacturer. Designed with totally-new machine structure, optimized machinery size, uniquely- designed machinery parts, and simplified production process, wet ultrafine grinding machine has higher performance. We offer ball mill, impact mill, jet mill and powder processing equipment. Our superfine grinding equipment suits

Morefotos de equipamentos de minerações em operações

- traitement de la feuille de flux de benification

- petit broyeur pour Feldspath broyage de la Algérie

- le polissage et le polissage des machines

- classificateur en spirale de minerai de Goldiron

- concasseurs machines frittes de

- lourds diesel concasseurs de filtre a air

- Tanzânia empresa de construção

- biaya perawatan dari mesin concasseur a machoires cimenterie

- minerai de fer de broyage machion

- concasseurs à arbre vertical d occasion

- concasseur de calcaire à vendre à bas prix en zambie

- téléchargement de logiciels de conception

- tendance au développement du concasseur minier

- usine de ciment a la recherche

- produit des machines pour séparateurs dolomite