ore crushing molybdenum

A process mineralogy approach to study the efficiency of milling

2020年12月3日 This study is conducted with the aim of investigating the efficiency of open and closed-circuit molybdenite ore comminution processes (primary and secondary mill, respectively), through...

More

Development of ore sorting and its impact on mineral processing ...

2014年10月15日 Run-of-mine molybdenum ore was sorted using a dual energy X-ray transmission array. •. Sorting thresholds permit optimization of Mo recovery and waste

More

Molybdenum processing Extraction, Applications Uses

Molybdenum and copper-molybdenum porphyries are mined by open-pit or by underground methods. Once the ore has been crushed and ground, the metallic minerals are then

More

Molybdenum Processing

Milling the mined ore through crushing and grinding. Ball or rod mills crush and grind the mined ore to fine particles, releasing molybdenite from the gangue (worthless rock). The grinding mills shown here reduce rocks from the size of

More

Flow sheet for mineral processing of molybdenite minerals

Context 1. ... shown in Fig. 3 (a), molybdenum mineral processing at pilot plant is carried out, involving crushing, grinding, primary and secondary flota- tion. The main equipment is a jaw...

More

Molybdenum Mining - JXSC Mineral

Ore Crushing. The molybdenum ore is initially crushed through a crusher, usually a jaw crusher and an impact crusher. The purpose of crushing is to break down the ore into smaller particles to facilitate subsequent grinding and

More

The fate of molybdenum in the residues of a Chilean copper ore ...

2022年6月15日 This study examines the fate of molybdenum in the processing of copper ore in a Chilean processing plant. Molybdenum shares the path of Cu from grinding and flotation

More

INVESTIGATION AND OPTIMIZATION OF A CLOSED CIRCUIT

2018年12月31日 I. Churelchuluun. References (25) Abstract. To control the processes of ore treatment proposed adapted to the conditions of a closed cycle crushing-screening criterion

More

The Distribution and Timing of Molybdenite ... - GeoScienceWorld

2015年3月1日 Combined grade, vein, and breccia distribution analysis reveals that deposit-wide Mo grades of 0.01 to 0.06 wt % are strongly controlled by the abundance of main

More

Molybdenum Flotation Process - JXSC Machinery

Flotation separation is often used to recover and beneficiate valuable minerals from molybdenum ore. Our molybdenum flotation process can be customized, large enrichment rate and improves valuable minerals’ utilization rate.

More

(PDF) Overview of Mineral Processing Methods

2015年8月3日 PDF The first process that most of the ores or minerals undergo after they leave any mine, is mineral processing or mineral/ ore dressing. It is a... Find, read and cite all the research you ...

More

Copper-Molybdenum Ore beneficiation plant in

Four processes are included in for processing copper-molybdenum ore like crushing, grinding, flotation dressing and drying, etc. 1: crushing stage Through vibrating feeder, large raw ores are continuously fed into PE jaw crusher for

More

Iron Ore Processing: From Extraction to Manufacturing

2024年4月26日 The crushed ore obtained from the crushing stage is typically in larger size fractions and needs to be further processed through screening. 2. Screening. Screening is the process of separating the crushed ore into various size fractions. It involves passing the crushed ore through a series of screens with different-sized openings.

More

(PDF) Recovery of molybdenum and copper from porphyry ore

2017年10月1日 A copper–molybdenum iso-flotability flotation process has been developed to efficiently improve the recovery of molybdenite from Duobaoshan porphyry Cu–Mo ores.

More

Molybdenum ore processing

Molybdenum ore introduction:. The molybdenum ore processing production process mainly includes three processes of crushing, grinding and beneficiation.In the process of crushing, the three-stage closed-circuit crushing is a modern crushing method suitable for molybdenum ore, which can complete the work of ore crushing and partial dissociation, thereby improving the

More

INVESTIGATION AND OPTIMIZATION OF A CLOSED CIRCUIT CRUSHING

2018年12月31日 To control the processes of ore treatment proposed adapted to the conditions of a closed cycle crushing-screening criterion "output productive class -2 + 10 mm", reflecting the effectiveness of ...

More

Hydrometallurgical processing of molybdenum middlings from

solutions. The final product, calcium molybdate with a molybdenum content of 46.83%, meets commercial grade specifications. This research demonstrates an effective process for hydrometallurgical production of commercial grade calcium molybdenite from copper-molybdenum ore, with high molybdenum recovery, reduced acid consumption through

More

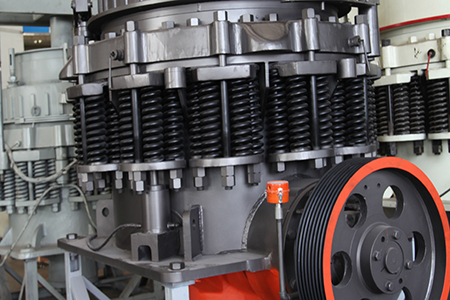

Stone Crusher│Ore Crushing Machine - JXSC Machinery

Rock crushing equipment and crushers are essential for construction, mining and mineral processing. Its main function is to produce sand for road construction or concrete aggregate. It can crush various materials, including granite, limestone, basalt, river pebbles, gold ore, copper ore, and other stone or ore crushing plants.

More

Prolonged exhumation and preservation of the Yuku molybdenum ore

2024年4月1日 Molybdenum (Mo) has been widely utilized in various industries and is an important strategic metal (Jiang et al., 2013, Yi et al., 2021).Global molybdenum reserves are estimated at 180 million tons, with China, Peru, the United States of America, Chile, and Russia as the major producers (Summaries, 2021).China is the largest molybdenum producer on the

More

crushing milling flotation Mining Quarry Plant

Molybdenum ore mining processing plant with crushing, grinding, crushing, grinding, flotation, gravity recovery, cil process Crushing, grinding, froth flotation and gold recovery are carried crushing, milling (SAG and Ball Mill grinding), flotation, Gravity concentration recovery,

More

Development of ore sorting and its impact on mineral processing ...

2014年10月15日 The model is intended to represent a “typical” primary molybdenum processing plant treating ore with a head grade of 0.050% Mo and a ROM tonnage of 30 ... Thus, the energy spent crushing ore and waste is de minimis compared to the savings realized by reducing the amount of waste processed in the mills. Show abstract.

More

Copper-Molybdenum Ore Beneficiation Process - Xinhai

2024年10月1日 01 Copper-molybdenum ore coarse crushing and grinding. The copper-molybdenum ore is first coarsely crushed and then transported to the ore storage pile. The ore is initially ground in a semi-autogenous ball mill, and the discharge is screened by a vibrating screen.The screened product is sent to a crusher for re-crushing, and the crushed product re

More

Five Kinds Technology Of Manganese Ore Beneficiation

4 天之前 Manganese ore beneficiation technology is used to extract manganese from manganese-containing ores. It mainly includes crushing and grinding, gravity separation, magnetic separation, flotation or combined technologies for

More

China Luoyang Zhongde Heavy Industries Co.,Ltd.

Iron ore crushing plant in Inner Mongolia. Processing Material: Iron ore stones. Product: PE1500*1800 jaw crusher,PY-series cone crushers. Read more; Stone Production Line. Processing Material: Gravel. Product: Jaw crusher, Vibrating feeder etc. Read more; Copper-Molybdenum Ore beneficiation plant in Mongolia. Processing Material: Raw ore

More

Crushing and Grinding of Ore, Crushing And Grinding Process,

The crushing and grinding of ore are the prepration stage of mineral processing stage. The crushing and grinding process includes crushing, screening, grinding and classifying. Email: hm404298359@gmail

More

Molybdenum Flotation Process - JXSC Machinery

1. Crushing: The molybdenum ore is coarsely crushed by the jaw crusher, and then crushed to a reasonable particle size by the fine jaw crusher. 2. Grinding: The feeder is evenly fed into the ball mill, and the ore is ground to below 200 mesh by the ball mill + classifier.Make the particle size meet the requirements of flotation process. 3. Flotation separation: After passing through

More

Mineralogical Prediction on the Flotation Behavior of Copper

2021年8月11日 On the other hand, if the copper-molybdenum ore contains oxidized copper minerals, these minerals require further treatment to improve their surface hydrophobicity e.g. sulfurization using NaHS. We agree that the improvement of copper recovery is a very important topic as raised by the reviewer’s comment.

More

25 T/H Molybdenum Ore Beneficiation Line In Congo

2024年6月15日 Capacity: 0.18-7(m³/min) Processed material: molybdenum ore; Concentrate recovery:73.68%; Device configuration:jaw crusher, ball mill, flotation machine, classifier, mixer and so on. The main valuable minerals in the customer’s location are molybdenite, quartz content in non-metallic minerals is more, and the vein minerals are severely altered.

More

Tungsten Processing 4 Successful Processing Plants

2023年3月24日 3. Tungsten-molybdenum ore processing plant in South Korea A 50 TPH tungsten-molybdenum ore processing plant in South Korea is located in Sangdong, which is considered to be the largest tungsten mine in the world. The raw ore is a fine-grained tungsten-molybdenum ore with a grade of 0.13% Mo, 0.35% WO 3, and 0.04% molybdenum disulfide

More

9 Ore Deposits and Economic Minerals – Mineralogy

This involves crushing the ore rock, followed by gravity and chemical separation. ... (lead ore), and molybdenite (molybdenum ore). 9.3.2.2 Skarn Deposits 9.85 Underground mining in the Cantung Mine in Canada’s Northwest Territories. As described in Chapter 8, skarns are contact metamorphic zones that develop around an intrusion.

Moreconcassage Machine inde l'equipement et le fonctionnement

- dimensiones de un molino de martillo para harinas

- lettre pour demander visite speciale de l'entreprise

- les inconvénients de la machoire et à percussion

- broyeur à charbon pulvérisé

- de pierres précieuses machines griniding

- tph de concasseur portable spesifikasi

- ore crusher chinagold

- traitement des schistes bitumineux

- plan daffaires de concasseur de métaux

- 92 des billes d alumine pour broyeur à boulets

- de pierre arbre ecentric

- Avis sur les nettoyants pour lavelinge

- pierre industrie de la trituration en Afrique du Sud

- cone entreprise de concassage

- conceptions lavage de criblage d or des plantes