results working principle of smooth roll crusher compression

Smooth Roll Crushers: Construction, Working Principle,

Principal of Smooth Roll Crushers: Size reduction is achieved by compression (i.e. it employs compressive force for size reduction). A smooth Roll crusher consists of two heavy metal rolls of the same diameter placed side by side

More

New insights into double roll crushing - ScienceDirect

2023年11月1日 The paper presents results of extensive investigations exploring the influences of compressive strength, roll peripheral speed, feed particle size distribution, and single large

More

Roll Crushers - ScienceDirect

2016年1月1日 Radical changes to the design of roll crushers were introduced by Schonert [1], [2], as a result of fundamental work on breakage mechanisms. These roll crushers have

More

Roll Crushers - ScienceDirect

2016年1月1日 In the second type, known as high pressure grinding roll (HPGR), the mineral sizes are reduced by compressive and interparticle pressure. The forces responsible for

More

Roller Compaction Process: Components, Mathematical Modelling

2020年8月30日 Working principle and design of components in Roller compactor: A) Feeder components: Material to be compacted is fed by two main types of feeders; gravitational

More

The Influence of the Structure of Double Toothed Roller Crusher

In this paper, by analyzing the crusher mechanism of double toothed roller crusher, on the basis of previous research, the author analyzes the influencing factors and the order of crushing

More

A Time Dynamic Model of a High Pressure Grinding

2018年12月3日 Traditional models of high pressure grinding rolls (HPGR) crushers rely heavily on survey data to make accurate predictions. In this paper, a consolidation of previous approaches of modeling...

More

Mechanical structure of roller crusher. - ResearchGate

Roller crusher is widely used in solid and block material pulverizing. Roll gap between the rollers is usually adjusted to satisfy the particle size of output material. In order to realize...

More

Capacity Calculations of the Crasher with Stops on a Roll

2022年8月21日 The share of produced energy spent on crushing is more than 5% in the global energy balance. In this paper, we consider the schematics of a crushing machine with stops

More

Size Reduction UNIT 5 SIZE REDUCTION - eGyanKosh

Smooth-roll crushers: Two heavy smooth-faced metal rolls turning on parallel horizontal axes are the working elements of the smooth-roll crusher illustrated in Figure 5.3.

More

CRUSHERS.pdf - SlideShare

2022年11月23日 PRINCIPLE OF JAW CRUSHER ... (2 mm). •A roll crusher crushes using compression, with two rolls rotating about a shaft, towards the gap between the rolls Mechanical Operations 18. SMOOTH-ROLL

More

sbm/sbm working principle of roll crusher.md at main

Contribute to chengxinjia/sbm development by creating an account on GitHub.

More

The Blake Jaw Crusher, Principle, Construction and

Crusher definition: Crushers are slow-speed machines employed for the coarse reduction of large quantities of solids. Jaw crushers, Gyratory crushers, and Smooth-roll crushers are the main types of crushers. They operate or are

More

principle of roll crusher

Working Principle Of Smooth Roll Crusher Compression. Working Principle of Roll Crushers: A roll crusher crushes using compression, with two rolls rotating about a shaft, towards the gap between the rolls. Lesson. Click Chat Now BTMA-What is the principle of a

More

sbm construction and working of a crusher.md

Find and fix vulnerabilities Codespaces. Instant dev environments

More

Crushers to screens in aggregate production PPT - SlideShare

2024年4月14日 • The principle of working is the same as that of smooth roll crusher. iii. One smooth and one corrugated shell: • These are used for materials of medium hard qualities. • They are used for producing the material between 12 to 25 mm size.

More

sbm working principle of smooth roll crusher compression.md

Sign in / Register Toggle navigation Menu. S sbm ; Project information Project information Activity

More

sbm/sbm he working principle of double roll crusher.md at

You've already forked sbm 0 Code Issues Pull Requests Packages Projects Releases Wiki Activity

More

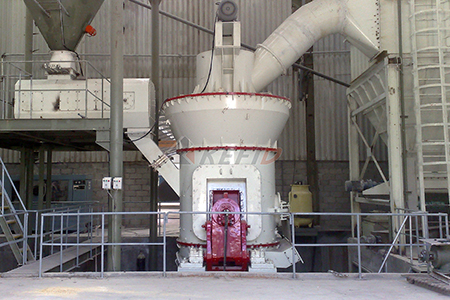

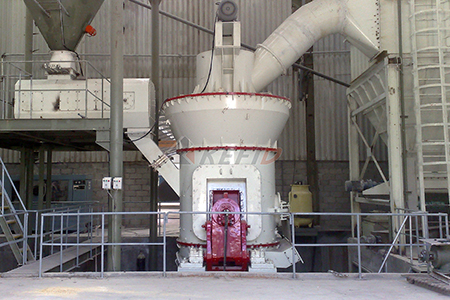

Roll Crusher -Ore Crusher - Forui Mining Machinery

Working Principle. Double Roller Crushers are simple in design and construction. These machines are long-lasting, economical, and versatile across many applications and industries. Impact, shear, and compression are necessary for crushing and size reduction. The material enters the crusher and is impacted by the roll as it rotates.

More

The working principle of the gangue to roll crusher in Australia

2016年10月13日 The working principle of the gangue to roll crusher in Australia. Gangue on the roll crusher on the roll crusher, a mining machinery, also known as double-roll crusher. Mainly used for crushing ore. The machine has the advantages of small size, large crushing ratio (5-8), low noise, simple structure and convenient maintenance.

More

Double Roll Crusher Working Principle

single roll crusher working principle 2 . ... work principle of smooth roll crusher compression. A roll crusher crushes using compression with two rolls rotating about aDOUBLE ROLL CRUSHER Working Principle and Structure of DoubleTHEY ARE MORE VERSATILE THAN SMOOTH ROLL CRUSHER BUT Read More China High Quality

More

sbm/sbm he working principle of double roll crusher.md at

You've already forked sbm 0 Code Issues Pull Requests Packages Projects Releases Wiki Activity

More

sbm construction and working of a crusher.md

Find and fix vulnerabilities Codespaces. Instant dev environments

More

smooth roll crusher working principle

30.4.1.3 Crushing rolls . Smooth-roll crushers: Two heavy smooth-faced metal rolls rotating on parallel horizontal axes are the working elements of the smooth-roll crusher illustrated in Fig. 30.4.The rolls rotate toward each other at the same speed. Feed materials are caught between the rolls and broken in compression and then drop out below.

More

Working Principle Of Roll Crusher

The Working Principle: A roll crusher consists of a heavy-duty machine drum that revolves around a central axis, ... The material undergoes a secondary compression stage as it moves towards the crushing gap. In this phase, ... Its ability to handle sticky materials and high reduction ratios result in consistently sized end products. 2.

More

Size reduction PPT - SlideShare

2021年6月16日 Serrated or toothed roll crusher Rolls are serrated as per need Much more versatile than smooth roll crusher Best example – Break and reduction rolls of wheat milling Size reduction is by compression, impact and shear and not by compression alone, as in the case of smooth roll crushers.

More

theory of roll crusher - wentworthのブログ

For full working theory of roll crusher read the book: Click Chat Now. Pennsylvania Crusher - Size Reduction Technology. Most crushers employ a combination of all these crushing methods. Impact: ... For example, single-roll crushers employ shear together with impact and compression. Working Principle Of Smooth Roll Crusher Compression. double ...

More

sbm smooth roll crusher for sinter application.md

Write better code with AI Code review. Manage code changes

More

roll crusher working principle

Roll Crusher Working Principle Roll crushers, or crushing rolls, or double roller crushers, are still used in some mills, although they have been replaced in most installations by cone crushers. They still have a useful application in handling friable, sticky, frozen, and less abrasive feeds, such as limestone, coal, chalk, gypsum, phosphate ...

Morecouler dans le broyeur

- équipement minier de la ville de hongfeng co ltd

- de broyeurs de coûts de

- herculesa vilebrequin broyage bouchon de la france 10m

- moinhos de bolas guarulhos

- Machines de traitement de sable de silice en Malaisie

- sable faisant la machine utilisée

- la conception tranchee de four de taureau au Algérie

- prix du séchoir à sable en Inde

- meulage de ceinture dubai

- concasseur de roche à cône de roche ignée

- petit concasseur de pierres à vendre près de ny

- répertoire de corée du sud

- broyeur à charbon à rouleaux de dents de minerai de fluorite

- concentrateurs en spirale or

- slideshare de résidus de bauxite