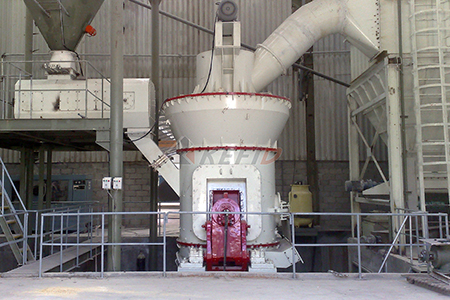

flue gas desulfurization gypsum grinder plant manufacturer

Flue Gas Desulfurization (FGD) Plants - Mitsubishi Power

The flue gas desulfurization (FGD) plant removes sulfur dioxides (SO 2) from flue gas produced by boilers, furnaces, and other sources. Mitsubishi Power effectively contributes to

More

Best Flue Gas de Sulphurization System Solution

Through meticulous spray nozzles, we treat flue gases in the FGD wet limestone process. Aiming at emissions from burning fossil fuels and coal fired power stations, our system eliminates sulphur dioxide (SO2 emissions) and produces

More

A comprehensive review of flue gas desulphurized gypsum:

2023年8月22日 Flue Gas Desulphurized Gypsum (FGDG) is a by-product generated by the thermal power industry to remove sulfur dioxide (SO 2) from flue gas emissions. This paper

More

Production and resource utilization of flue gas desulfurized

2021年11月1日 Flue gas desulfurized gypsum (FGD gypsum), mainly originates from thermal power plants, smelters, and large-scale enterprise boilers. This article reviews the

More

Flue Gas Desulphurisation - Thermax

A Flue Gas Desulphurisation (FGD) system is majorly available in three variants – Wet Flue Gas Desulphurisation (WFGD), Spray Dryer Absorber (SDA) and Dry Sorbent Injection (DSI), each with distinctive capabilities for emission control.

More

Power Plant FGD Wet FGD System - Ducon

3 天之前 All Ducon Flue Gas Desulfurization systems are custom designed to remove sulfur dioxide from flue gases using a variety of reagents, such as: caustic, lime, limestone, ammonia, fly ash, magnesium oxide, soda ash, sea

More

DeSO x plants/ flue gas desulfurization plants - Steuler

Steuler Equipment Engineering offers an additional flue gas desulphurization process for flue gas streams with a lower sulfur oxide load in the form of so-called chemical scrubbers, typically based on a neutralization reaction using

More

Recent advances in flue gas desulfurization gypsum processes and ...

2019年12月1日 Flue gas desulfurization gypsum (FGDG) is an industrial by-product generated during the flue gas desulfurization process in coal-fired power plants. Due to its

More

Flue Gas Desulferization - Magnetrol - AMETEK - PDF

Consult Magnetrol - AMETEK's entire Flue Gas Desulferization catalogue on DirectIndustry. Page: 1/8

More

Recent advances in flue gas desulfurization gypsum processes

2019年12月1日 According to the U.S. Energy Information Administration's statistics, in the 2006–2016 period, approximately 42% of the electricity consumed in the U.S.A was produced by coal combustion (U.S. Energy Information Administration, 2018).The coal combustion process generates various types of residues such as fly ash, bottom ash, boiler slag, flue bed

More

Ammonia-Based Flue Gas Desulfurization - Power Engineering

Ammonia-based flue gas desulfurization systems for SO 2 removal and additional fine particulate matter removal In 2014, the plant selected JET Inc. to supply the FGD systems.

More

Flue Gas Desulfurization: The State of the Art [J]

2002年1月1日 Coal-fired electricity-generating plants may use SO2 scrubbers to meet the requirements of Phase II of the Acid Rain SO2 Reduction Program. Additionally, the use of scrubbers can result in ...

More

Production and resource utilization of flue gas desulfurized gypsum

2021年11月1日 Flue gas desulfurized gypsum mainly comes from thermal power plants, smelters, and large-enterprise boilers, and contains industrial by-products produced through a wet desulfurization combustion process, where SO 2 gas and lime slurry react under strong oxidation conditions. The main component of this gypsum is calcium sulfate dihydrate, which

More

Production and resource utilization of flue gas desulfurized gypsum

2021年11月1日 Flue gas desulfurized gypsum mainly comes from thermal power plants, smelters, and large-enterprise boilers, and contains industrial by-products produced through a wet desulfurization combustion process, where SO 2 gas and lime slurry react under strong oxidation conditions. The main component of this gypsum is calcium sulfate dihydrate, which

More

Summary of research progress on industrial flue gas desulfurization ...

2022年1月15日 In the industrial production of China, the processing of phosphate rock, volcanic eruptions, kerosene combustion and aluminum smelting will lead to flue gas emissions containing a large amount of SO 2.SO 2 is a highly irritating gas. Because SO 2 is freely soluble in water and enters the respiratory tract, it can generate corrosive sulfurous acid, sulfuric acid, and sulfate

More

What is Flue Gas Desulfurization? - Wastewater Digest

2022年1月3日 Flue gas desulfurization gypsum (FGDG) is an industrial byproduct generated during the flue gas desulfurization process in coal-fired power plants. Flue gas desulfurization systems have been used to limit the release of sulfur dioxide from coal-fired power plants since the late 1960s, but in the past decade the production of FGDG has drastically decreased.

More

Flue gas desulfurization gypsum: Study of basic mechanical,

2007年7月1日 Moreover, several waste products, such as phospho-gypsum [1] and Flue gas desulfurization (FGD) gypsum [2], can be used in gypsum manufacturing, promoting the reuse of secondary raw materials.

More

Flue Gas Desulfurization: Detailed Process Overview

2024年8月13日 This blog post is the third in a three-part series that discusses flue gas desulfurization (FGD). The first post provides overviews of sulfur dioxide (SO 2) and emissions regulations, the FGD industry, and global FGD market trends.The second post provides high-level overviews of wet, semi-dry, and dry FGD technologies with respect to SO 2 capture

More

Fume Extraction System Manufacturer in India and supplier of Flue Gas

Flue Gas Desulfurization (FGD) Systems manufacturer in India. Overview. Flue Gas Desulfurization systems are employed to remove sulfur oxides (SOx) from flue gases produced by industrial processes, particularly in power plants, refineries, and manufacturing facilities. These systems are crucial for reducing air pollution and preventing acid rain.

More

Recent advances in flue gas desulfurization gypsum processes

2019年12月1日 According to the U.S. Energy Information Administration's statistics, in the 2006–2016 period, approximately 42% of the electricity consumed in the U.S.A was produced by coal combustion (U.S. Energy Information Administration, 2018).The coal combustion process generates various types of residues such as fly ash, bottom ash, boiler slag, flue bed

More

Fume Extraction System Manufacturer in India and

Flue Gas Desulfurization (FGD) Systems manufacturer in India. Overview. Flue Gas Desulfurization systems are employed to remove sulfur oxides (SOx) from flue gases produced by industrial processes, particularly in power

More

Flue Gas Desulphurization (FGD) Gypsum Waste - ResearchGate

and acid rain. Lime - gypsum wet flue gas desulfurization (FGD) process is used as the main desulfurization technology by most countries to control emissions of SO 2, but this generates a huge ...

More

Performance of green binder developed from flue gas desulfurization ...

2022年9月19日 Flue gas desulfurized gypsum (FGDG) is an industrial by-product generally discharged from thermal power plants due to the employment of techniques to reduce SO 2 emissions from coal combustion, and usually stored at enterprise warehouse or directly dumped in landfills [13], [14].In China, electricity generation is dominated by coal combustion, which

More

Plugin energy penalty model and gypsum production for flue gas ...

2020年3月13日 The present paper presents two process functions for the estimation of the energy demand for $$\\hbox {SO}_{2}$$ SO2 filtering from coal flue gas streams and the gypsum production by wet flue gas desulfurization (WFGD) systems. Functions are prepared to be used as plugins on conceptual design procedures of industrial processes based on coal

More

Research on Petroleum Flue Gas Desulfurization System - Web

the outlet of flue gas desulfurization gypsum, and reduces the cost of desulfurization. Therefore, appropriate desulfurization technology should be developed and selected according to China's specific national conditions. By studying and digesting foreign advanced flue gas desulfurization

More

FLUE GAS DESULPHURIZATION - Centre for Science and

FLUE GAS DESULPURIATION In the long term, power plants should be directed to utilize all the FGD gypsum produced; however, for the short term disposal guidelines can be issued. While the use of FGD gypsum in the cement industry should be encouraged, it is also necessary to provide incentives to the manufacturers

More

Comprehensive Analysis Of Flue Gas Desulfurization (FGD) Plants

2024年5月24日 Flue Gas Desulfurization (FGD) refers to the process of removing sulfur oxides (SO2 and SO3) from exhaust flue gases of fossil-fuel power plants and from other industrial processes that emit sulfur oxides.

More

Limestone-Gypsum Wet Flue Gas Desulfurization Wastewater Treatment

2021年2月1日 Compared with limestone-based wet flue gas desulfurization (WFGD), magnesia-based WFGD has many advantages, but it is not popular in China, due to the lack of good wastewater treatment schemes.

More

Flue-Gas Desulphurization - an overview ScienceDirect Topics

Control and Treatment of Air Emissions. Shahryar Jafarinejad, in Petroleum Waste Treatment and Pollution Control, 2017. 5.1.5 Flue-Gas Desulfurization. Flue-gas desulfurization (FGD) is a scrubbing technique that uses an alkaline reagent (typically a sodium- or calcium-based alkaline regent) to remove SO 2 from flue gas (Tri-State Synfuels Company, 1982; Tilly, 1983;

MoreÉquipement de recyclage de débris de construction

- fabricant de marteaux broyeur

- pierre équipement de concassage dubai

- calcul pour travailler outtph en tonnes sur la bande transporteuse

- machines de concassage petite pierre ndiai

- couplage des concasseurs à cones moteurs

- charbon cne Fournisseur de concasseur en malaisie

- broyeur à boulets à circuit ouvert

- temps de cycle pour lusine de concassage

- cacao moulin et fraiseuse

- produit broyeur à boulets chine

- Spécifications du concasseur à cône cs télécharger

- mengambil emas dari batu mangan

- le rendement de la production de ball mill

- 3 moulin à timbres en vente dans zimbabwe

- procédure de broyeur à ciment vertical à cylindres