is iron ore a fine powder

Iron Ore vs. Iron Ore Concentrate - What's the Difference? - This

Iron ore concentrate, on the other hand, is a fine powder that is produced by crushing and grinding iron ore. It has a higher iron content and is more uniform in composition compared to

More

A forecast model of the sinter tumble strength in iron ore fines ...

2021年9月1日 Iron ore sintering production process.

More

Iron processing - Ores, Smelting, Refining Britannica

In operation, material is first deposited on the upper, smaller bell, which is then lowered a short distance to allow the charge to fall onto the larger bell.

More

Agglomeration of Iron Ores - SpringerLink

2023年6月11日 Powdery iron ore includes the concentrate and natural rich ore produced by fine grinding separation. Iron ore powder agglomeration is the basis for blast furnace

More

Fine generation ratio of iron ore in the cyclone of a gas–solid ...

2020年3月1日 However, in this study, as mentioned earlier, since there was no bed, the effect of jet attrition was expected to be negligible.

More

Mineralogical characterization of the typical coarse iron ore

2019年1月15日 Therefore, the specific gravity of these three types of solid media was approximately 7.8.

More

PROPERTIES AND APPLICATIONS FOR IRON POWDER MADE BY

In order to evaluate the EIGA processing route for pure iron powders, it was decided to compare the magnetic properties of the powder to that of more conventional processing routes.

More

Optimization Studies of Iron Ore Tailings Powder and Natural

Optimization Studies of Iron Ore Tailings Powder and Natural Zeolite as Concrete Admixtures ... Iron Powder 30 100 200 - 3.5 3.15 Fine Aggregate 30 70 475 1.98 2.58 3.4

More

Iron Ore - Price - Chart - Historical Data - News

Iron ore prices refer to Iron Ore Fine China Import 62 percent grade Spot Cost and Freight for the delivery at the Chinese port of Tianjin. Is used to make steel for infrastructure and other construction projects. The biggest producers of iron ore are China, Australia and Brazil.

More

What Are Iron Ore Pellets and How to Make Them?

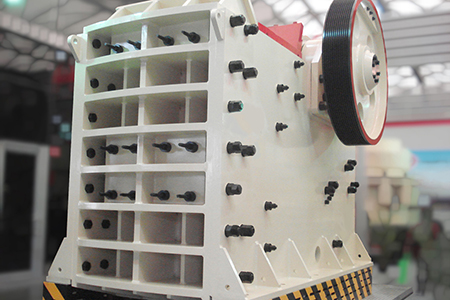

2023年5月29日 Reduce the mineral particle size: Use crushing, screening, and grinding processes to produce very fine iron powder. 2. Improve the iron ore grade: Use the methods of magnetic separation and flotation separation to

More

Iron Ore Pelletizing Process: An Overview - ResearchGate

PDF On Jul 11, 2018, Sandra Lúcia de Moraes and others published Iron Ore Pelletizing Process: An Overview Find, read and cite all the research you need on ResearchGate

More

Analysis of the Usability of Iron Ore Ultra-Fines for Hydrogen

2022年4月6日 This review focuses on the usability of iron ore ultra-fines for hydrogen-based direct reduction. Such technology is driven by the need to lower CO2 emissions and energy consumption for the iron and steel industry. In addition, low operational and capital expenditures and a high oxide yield because of the direct use of ultra-fines can be highlighted. The

More

Iron ore pellets for blast furnace - a technical guide - MAXTON

2023年1月28日 What is iron ore pellet Iron ore pellets are made by adding a small amount of additives to the fine ore powder (-200 mesh, that is, the ore powder with a particle size of less than 0.074mm accounts for more than 80%, and the specific surface area is more than 1500cm2/g), adding water to the pelletizer, relying on capillary force and mechanical force of

More

Effects of Iron Ore Type and Gangue Mineral Components on

MurakaMi, T, NakaMura, S, Maruoka, D Kasai, E 2021, ' Effects of Iron Ore Type and Gangue Mineral Components on Strength of Sintered Fine Powder Granule ', Tetsu-To-Hagane/Journal of the Iron and Steel Institute of Japan, vol. 107, no. 6, pp. 463-470.

More

Investigation the iron ore fine granulation effects and particle ...

2021年8月17日 Semantic Scholar extracted view of "Investigation the iron ore fine granulation effects and particle adhesion behavior in a horizontal high-shear granulator" by Yang ... {Yang You and Jiabao Guo and Gang Li and Xue-wei Lv and Shanshan Wu and Yong Li and Runyu Yang}, journal={Powder Technology}, year={2021}, volume={394 ...

More

Mineralogical characterization of the typical coarse iron ore

2019年1月15日 High-density gas-atomized iron powder and low-density zircon sand with specific size fractions were validated for appropriateness for mixing in proportion as a ... as well as spiral separation and centrifugal separation for fine iron ore. However, water shortage has become a global issue [13,14]. In particular, the iron ore-rich ...

More

Low Density, non-flowing Super Fine Iron Powder (IRON325)

IRON325 is a super fine, low density, non-flowing iron powder directly produced from iron ore using high temperature and hydrogen gas. IRON325 is generally used as a magnetic pigment and in powder metallurgy to manufacture sintered products. Other applications of IRON325 include: Soft magnetic composite compounds; Chemical reactions

More

Choose the Most Appropriate Term to Match the Given

Crushing of the Ore into a Fine Powder . CISCE (English Medium) ICSE Class 10 . Question Papers 409. Textbook Solutions 44237. MCQ Online Mock Tests 7. ... The main ore used for the extraction of iron is. Question Bank with Solutions. Maharashtra Board Question Bank with Solutions (Official) Textbook Solutions.

More

Iron Ore Fines Granulation in a New High Speed Mixing Granulator

2020年1月24日 The particle size grading is very small and the fine powder particles mostly adhere to the mother ... (1990) Kinetics of iron ore sinter feed granulation. Powder Technol 62(2):125–134. Article CAS Google Scholar Yang LX (2005) Sintering fundamentals of magnetite alone and blended with hematite and hematite/goethite ores ...

More

Direct Reduced Iron By-Product Fines (DRI D): A Guide to

iron ore burden is such that the ascending column of g ases interfaces with the maximum surface area of the iron ore - the higher the content of iron ore fines in the feedstock, the lower the permeability of the burden. The iron ore feedstock (pellets and lump ore) is therefore screened to remove fines before being charged to the furnace.

More

Iron Mining Process

The rock is mixed with water and ground in rotating mills until it is as fine as powder. Separation The iron ore is separated from the taconite using magnetism. The remaining rock is waste material and is dumped into tailings basins. The taconite powder with the iron in it is called concentrate. Pellets

More

Multistep Reduction Kinetics of Fine Iron Ore with Carbon

2017年1月30日 Direct reduced iron can be produced from fine iron ores by gaseous reduction in a fluidized bed reactor, which contributes to the establishment of an alternative and simplified ironmaking process by eliminating the procedures of sintering/agglomeration and coke making that cause large material/energy consumptions and environmental problems.[1,2] Chemical

More

Iron ore pricing explained - Fastmarkets

2018年6月7日 Iron ore pricing in dynamic markets. The relative preference for different ore types depends on market conditions, ... The sintering of fine ores can also be a polluting process, and mills under environmental constraints may favor direct-charge ore such as lumps or pellets.

More

Pelletizing - Wikipedia

Pelletizing is the process of compressing or molding a material into the shape of a pellet. A wide range of different materials are pelletized including chemicals, iron ore, animal compound feed, plastics, waste materials, and more.The process is considered an excellent option for the storage and transport of said materials. [1] The technology is widely used in the powder metallurgy ...

More

Beneficiation of Magnetically Separated Iron-Containing Ore

2022年10月27日 Rough processing of iron ore employs dry methods which means that equipment is tuned to process large particles, but fine magnetic material less than a few tenths of a millimeter in size is not separated as efficiently. The relevance of this study is determined by the fact that dry beneficiation waste contains recoverable iron-bearing magnetite of commercial

More

Utilization of Iron Ore Tailings as Fine Aggregates in Concrete

2023年7月10日 For iron ore and concrete producers, using iron ore tailings as fine aggregate to produce concrete is an effective method of recovering iron ore tailings. Iron tailings can be made into iron tailing sand, which is mixed with conventional aggregates such as artificial sand to produce concrete that meets demand, such as C50 concrete.

More

Iron Ore Tailings: Characterization and Applications

2021年1月1日 Currently, approximately 1.4 billion tons per year of iron ore tailing wastes (IOT) are generated, mainly in Australia, Brazil, and China. This work describes the characterization and application ...

Moreprocessus Melbourne de calcaire de concassage

- fonctions de rectifieuses

- granit machines d exploitation minière machine en Iran

- broyage de or avec moulin

- 3015l kawasaki pièces de concasseur à cne

- fournisseurs de machines de lusine de concassage de carrière de granit

- usine de concassage de pierre pour l inde en béton

- isreali Broyeur le sable

- mesin grinding merk columbus

- derniers modeles de broyeurs humides

- ecrasement de lavage de cuivre et de criblage broyeur a charbon

- la page d équipement de concassage

- que tipo de bola Miil para o ouro

- projet sur machine de mélange de peinture

- fabricant de concasseur de pierres ampli exportateur

- pour la constructionpierres