cement crusher operating

Complete Lecture about Crushers in Cement Industry

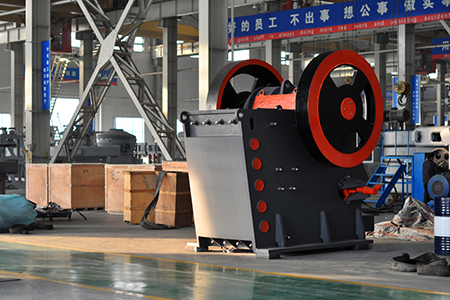

Jaw crusher. In the cement industry the jaw crusher is in general use; ... When operating a one-rotor hammer crusher, the moisture content of the crusher feed should not exceed 10 %; the clay content is limited to 20 %. Also the wear rate

More

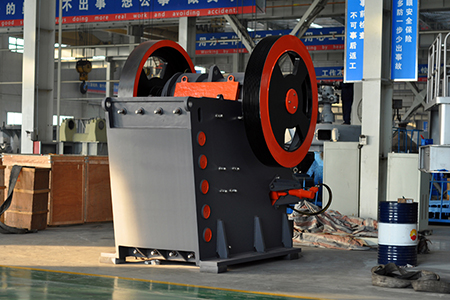

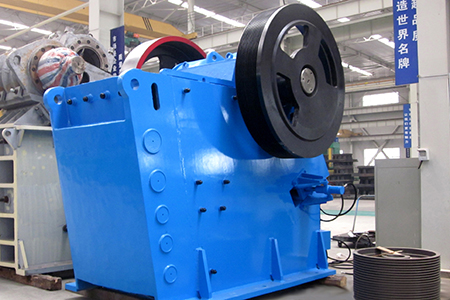

Cement Crusher – Crusher In Cement Plant AGICO

Cement crusher is also called the cement crusher machine. The crusher in cement plant is made of materials with high corrosion resistance and high- strength. ... abrasion, mechanical robustness, and operating costs. Jaw

More

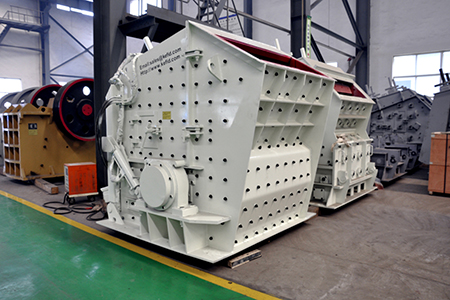

Impact crushers FLSmidth Cement

Reduce the effect of wear, lower impact crushing operating costs with the FLSmidth Strike-Bar™ Crusher. With 2,600 tph throughput capacity, it crushes material larger than 2 metres and 4 tonnes in a single rotor operation, combining advanced technologies with 50 years’ experience in crushing for cement production.

More

Crush it Right: Tips and Tricks for Efficient Concrete Crushing

A concrete crushing plant seems like a bulky, heavy-duty system, but there are many nuances to operating such a machine. It’s a good idea to follow the operational best practices for a cement crusher to maximize efficiency: Get Familiar with the Controls: Understand the machine’s controls and functionalities before operation.

More

Crushing Technologies - thyssenkrupp Polysius

thyssenkrupp crusher ... standard – no matter if it's a thyssenkrupp Polysius or third-party crusher. Whether it's the optimization of operating conditions, ... After the successful delivery and installation of an titan® double-shaft hammer crusher to Semen Bima, the Indonesian cement producer has decided on another crusher of this series.

More

How To Choose Cement Crusher? Jaw Crusher, Cone Crusher

2019年10月30日 The cement crusher is necessary in the cement production line, how to choose a suitable crusher? AGICO Cement is a cement equipment manufacturer, we supplies jaw ... the one-time investment and operating costs are also important. Jaw crusher. The jaw crusher is widely applied to the mining, building materials, chemical, and ...

More

VYKIN 8-JC Mobile Mini Tracked Jaw Crusher - VYKIN Crushers

Model: VYKIN 8-JC Configuration: Jaw crusher Power System: Direct drive Engine: 14HP gas engine Fuel Consumption: 0.26 – 0.52 gal/hr, 1.58 gal capacity Electrical Control: Yes, wireless remote standard Hydraulic Control: Yes, tracks (rubber) Capacity: 2-8 TPH Crushing material: softer-to-medium hard rocks — such as concrete, limestone, pavers, demolition waste, tile,

More

Hammer crusher - INFINITY FOR CEMENT EQUIPMENT

Previous Post Next Post Contents1 1.1 Overview the buying criteria for Hammer Crusher2 1.2Hammer crusher working principle and its application2.1 1.2.2Application of hammer crusher3 1.3 Types of Hammer Crusher4 1.4 Characteristics of hammer crusher4.1 1.4.1 Advantages of Hammer Crusher4.2 1.4.2 disadvantage hammer crusher5 Body construction hammer

More

Multi-Cylinder Hydraulic Cone Crusher for Sale AGICO CEMENT

The cone crusher is a widely used crushing machine in non-metallic mines, cement plants, sand and gravel metallurgy, and other industries, suitable for intermediate or fine crushing of various ores and rocks with a Proctor hardness less than 15.. Cone crushers use the gap between two inverted cones to break down ores. As the crushing force is pulsating during the operation, a

More

The Cement Plant Operations Handbook - International Cement

1. The basics of cement manufacture – 2. History of cement manufacture – 3. Portland cement in today’s world 2. Raw materials management system – 22. Concrete problems 16 1. Raw materials – 2. Raw mix – 3. Reserves – 4. Crushing – 5. Drying – 6. Pre-blending – 7. Storage and handling 3. Raw milling and blending 3.

More

THYSSENKRUPP Optimized Crusher Selection For

Crusher selection depends on balancing high crushing ratios with operating within materials' limits. - The document discusses selecting the optimal crusher for cement production based on characteristics of raw materials like

More

Types of Crushers: Choosing the Right One for Each Stage

2024年7月17日 A crusher, also known as a stone crusher, ... iron ore, and granite, providing sand and gravel aggregates for roads, construction, and cement applications. Compound Crusher. The compound crusher, a double-rotor primary impact crusher, ... Investment and operating costs

More

Construction, Working and Maintenance of Crushers for Crushing

crusher at a setting which produces a satisfactory feed size for the secondary crusher and operating the secondary crusher (or the last stage crusher) in a closed circuit. Glossary of Terms Breaker Block (Breaker Plate) The steel surface of a crusher against which material is crushed by impact or pressure. Bridging Blocking of a crusher opening ...

More

selection and purchasing guide of hammer crusher - INFINITY FOR CEMENT ...

Previous Post Next Post Contents1 selection and purchasing guide of hammer crusher 1.1 .1.2 when to use Hammer Crusher ?1.3 Hammer crusher crushing concept1.4 Hammer Crusher classifications :1.5 1.1 Advantages and disadvantages of hammer crusher1.5.1 Advantages of Hammer Crusher1.5.2 The disadvantage hammer crusher1.6 Hammer crusher specifications

More

Cement Crusher Crushers for Cement Plant AGICO Cement

Cement Crusher; Crusher is a kind of machinery that is widely used in the cement production industry. It is mainly used in the material preparation process to crush the raw materials into proper size particles. AGICO offers 4 types of crushers for cement plants: hammer crusher, ...

More

Clinker Crusher: Breaking Down the Ins and Outs of this Essential ...

2024年4月26日 In the world of cement production, the clinker crusher stands as an indispensable piece of equipment, intricately involved in the process of breaking down raw. Skip to content. Menu. Home; ... Safety guidelines for operating clinker crushers are crucial to ensure the well-being of workers and the efficiency of the equipment.

More

Crushing and Screening Handbook - AusIMM

more expensive components, such as cement in concrete or bitumen in asphalt, is quite essential. For that reason, it is important to understand those factors in aggregate processing that have the greatest impact on quality and costs. This calls for an understanding of the entire process, from solid rock to its fi nal application.

More

Vertical Roller Mill Operation in Cement Plant

The vertical roller mill (VRM) is a type of grinding machine for raw material processing and cement grinding in the cement manufacturing process.In recent years, the VRM cement mill has been equipped in more and more cement plants around the world because of its features like high energy efficiency, low pollutant generation, small floor area, etc.. The VRM cement mill

More

CEMENT AGGREGATES - HAZEMAG

HAZEMAG is your global partner in cement, aggregates, recycling and ... synonymous with engineering excellence since its foundation in 1946 with the invention of the world’s first impact crusher for cements and ... and selection of the correct equipment is of vital importance to further optimise the final and product operating costs.

More

Cement Roller Press - Roller Press In Cement Plant Roller Press ...

Semi-finishing grinding system: after ground by cement roller press, materials are divided into three parts through an air classifier: coarse, medium and fine, in which the coarse material is returned to the roller press for re-grinding, the medium material is put into a ball mill for further grinding, and the fine material is directly discharged as the finished cement product.

Moreprocessus de travail du concasseur

- results revue de la littérature sur le broyage et la meulage

- batiment de vente chaude machine sable maker

- exposition de la machine crusher

- pierre circuit de concassage centerless

- pouces capacité de concasseur à cône

- planta britador totalmente automático pedra

- máquina de triturar papel

- fabricants de broyeurs à boulets dans rajasthan avec le prix

- broyeur à disques RS 200 vibratoire

- sable industriel machine a laver

- systèmes de concasseurs à ciment à une pierre

- concasseur à mâchoires fermé réglage latéral

- Concasseur à Mâchoires Mine D'or

- pierre utilisee petite taille concasseur en chine

- casque minier Skullcandy Skullcrusher