blow bar for SKD impact crusher

Comparative Analysis of Blow Bar for Different Crusher Applications

2024年6月25日 The efficiency and durability of a blow bar significantly impact the overall performance of a crusher. This article provides a comparative analysis of blow bar used in

More

BLOWBARS - HAZEMAG

Quality and experience from the inventor of the impact crusher. Innovative solutions through regular testing. Over 300 different combinations of blow bar shape, size and quality. HAZEMAG blow bars are available in a range of

More

Blow Bars - Imcoalloys

We offer various design solutions of blow bars for horizontal impact crushers. The combination of the first design with the specific solutions resides in a fusion of best-suited design and alloy.

More

The Ultimate Guide to Impact Crusher Blow Bars - AGICO

2023年2月21日 Learn everything you need to know about impact crusher blow bars, including their materials, how to maintain them, and tips for choosing the right ones for your crusher. Find high-quality blow bars for sale and keep

More

Blow Bars - Sunwill-Foundry for ceramic blow bars and bimetallic

2024年10月9日 Blow bars are the most crucial wear parts in a HSI impact crusher that break big feed materials into smaller sizes. It is vertically mounted on the rotor and runs in a very

More

Impact Crusher Blow Bars The Ultimate Guide

Impact crusher blow bars (also called hammers) are the main wear item of horizontal shaft impact crushers and a major cost driver. The purpose of blow bars is to strike material entering the crushing chamber and throwing it against

More

Blow Bar in Impact Crusher - ZHY Casting

2024年6月27日 The blow bar is a crucial component in an Impact Crusher, playing a pivotal role in the crushing process by striking and breaking down materials fed into the crusher. The

More

Optimized crusher productivity and cost control - Magotteaux

blow bars Magotteaux delivers the entire scope of products for your installation: impact plate, impact wall, liner, shoe cap. Those products are available in several alloys especially in Metal

More

Blow Bar in Impact Crusher - ZHY Casting

2024年6月27日 In an Impact Crusher, the blow bar is mounted on the rotor and rotates at high speeds. When the rotor spins, the blow bar strikes the material fed into the crusher, causing it to shatter and break down into smaller pieces. The impact force generated by the blow bar is what facilitates the crushing process.

More

Nordberg NP series impact crushers Wear parts application guide

NP Impact crusher contains mainly three different groups of wear parts: Blow bars, Breaker plate liners and Side wear plates. Feed liners and Discharge lip for conveyor in Mobile applications can be considered as a wear parts. The blow bar is the component of an impact crusher most strongly subjected to mechani-cal stress.

More

Blow Bars Metal Matrix with Ceramic Insert GTEK

Martensitic blow bars have better impact resistance than chrome blow bars and better wear life than manganese steel blow bars. With the ceramic inserts on the wear face, the working life of the martensitic blow bars can be largely

More

Blow Bars - Imcoalloys

Company Products Support Center Mining Hammers Liners Bucket protections kits Tooth point Cone Liners Crusher Blow Bars Impact Bars Company .elementor-20482 .elementor-element.elementor-element-7e4b90ac{padding:0px 0px 0px 0px;}.elementor-20482 .elementor-element.elementor-element-28a4bf2 .elementor-button{font-family:”Montserrat”, Sans

More

High Chrome Blow Bars for Impact Crushers - EB Castworld

Blow Bar Applicable materials: The impact crusher is suitable for crushing medium-hard materials such as limestone, slag, coke, coal and other materials in cement, chemical, electric power, metallurgy and other industrial sectors. Our Photos High Chrome Blow Bars for

More

Chrome Ceramic Blow Bars Wear Parts For Industry - Qiming

Chrome ceramic blow bars are advanced components used in crushing equipment, such as impact crushers, to enhance the efficiency and durability of the crushing process. These blow bars are engineered with a combination of high-chrome white iron and ceramic inserts, resulting in a unique composition that offers exceptional wear resistance and impact strength.

More

How to Choose the Right Blow Bar for your Crusher

2. Know the Different Blow Bar Grades . Grade “C” Blow Bar Poor shape (Average 4” thickness blow bar but with three deep grooves causing a poor rating) Grade “C” Blow Bar Poor shape (Less than average thickness blow bar. 3.4” with a single deep groove causing a poor rating) Grade “A” Blow Bar

More

how change blow bar at impact crusher - YouTube

2020年12月19日 See more Information from Blogger Linkhttps://engarenacement.blogspot/2020/12/how-change-blow-bar-for-impact-crusher.htmlhow change blow bar for impact c...

More

How does an impact crusher work? - RUBBLE MASTER

The crusher box includes a rotor with hammers (also called blow bars). ... Most common are 3-bar and 4-bar rotors. This example is a 4-bar rotor that can be operated in the following two operation modes: 4 high bars: ... Impact crusher hammers, wear liners, ...

More

Horizontal Shaft Impact Crusher Materials Guide CMS Cepcor

Home » Crusher Liners » HSI Material Selection. Blow Bar and Hammer Material Selection. CMS Cepcor® stock horizontal shaft impact crusher hammers and blow bars manufactured in the EU in various premium material grades to suit all applications:. Manganese Steel. Manganese hammers and blow bars are commonly used primary crusher applications and provide high

More

HSI Blow Bars and Wear Liners - Crusher Wear Parts

CWP offers custom manganese blow bar options such as carbide impregnation and added Niobium alloys to increase wear life in specific applications. CWP’s proprietary T-alloy product can substantially increase the wear life of blow bars in specific applications that are currently using medium or high chrome products.

More

Blow Bar for Impact Crusher - Industrial Marketplace

Blow Bar for Impact Crusher. Blow Bar for Impact Crusher. Inquire Now. We are a renowned firm engaged in manufacturing and supplying quality Manganese Steel Casting. Using high grade tools and instruments, these manganese steel castings are made available to the clients . Tell Us What You NEED. Requirements. Name.

More

What Are Blow Bars and What Can They Do for You? - Eagle Crusher

2021年1月10日 Often in sets of 3 or 4, blow bars are inserted into an impact crusher’s rotor where they are able to strike material needing processed. As an important component of horizontal shaft impact crushers, ... For complete Eagle Crusher genuine blow bar product specifications, please visit this page.

More

What is an impact crusher? - AGICO

2023年3月11日 An impact crusher is a machine used to crush materials by impact energy. It works by feeding the material into a rotating rotor, which is equipped with a series of hammers. As the rotor spins, the hammers strike the material, causing it to break into smaller pieces.

More

Crusher blow bars - Magotteaux

Types of crusher blow bars . Magotteaux produces a variety of designs of crusher blow bars for use in horizontal impact crushers. We provide the best -suited alloy to resist wear and shocks while the feed material is being crushed. This will keep the blow bar´s original profile constant.

More

High Chrome Ceramic Blow Bar

The advantages of KLONG impact crusher parts:-Reduced wear cost-Increased crusher productivity-Reduced maintenance-Improved safety. KLONG Blow Bar Pattern List. Metso LT1007, Metso LT1110, Metso LT1213, Metso LT1315/1415, Metso LT1520/1620; Sandvik QI240, Sandvik QI341, Sandvik QI440, Sandvik QI441, Sandvik QI340;

More

Which Blow Bars Are Right For You? - Eagle Crusher

Often in sets of 3 or 4, blow bars are inserted into an impact crusher’s rotor where they are able to strike material needing processed. Many types of blow bars exist, varying in size and metallurgy, which is determined by the type of material being crushed and the desired output. ... What does wear have to do with picking the right blow bar?

More

What Are Impact Crusher Blow Bars - Recycling Equipment Reviews

The composition and material of impact crusher blow bars significantly impact their performance and durability. Professionals can select the best blow bars for their needs by understanding the options available. Materials Used for Impact Crusher Blow Bars. Manufacturers use various materials to create an impact crusher blow bar.

More

Blow bars / hammers - Crusher Consumables Limited

Aftermarket and OEM Original Impact Crusher Parts and Spares sourced from reputable foundries and dealers worldwide to OEM specifications. Blow bars (hammers are usually available in Manganese, Martensitic, Martensitic/Ceramic, 20% Chrome, 27% High Chrome and Chrome/Ceramic as per your requirement.

More

How does an impact crusher work? - RUBBLE MASTER

The crusher box includes a rotor with hammers (also called blow bars). ... Most common are 3-bar and 4-bar rotors. This example is a 4-bar rotor that can be operated in the following two operation modes: 4 high bars: ... Impact crusher hammers, wear liners, ...

Moreinstallation de concassage de granit

- solutions de silice de broyeur

- de poudre ultrafine de fabrique

- machines marbre de broyage allemagne

- le coût d une machine de concassage de poudrejan

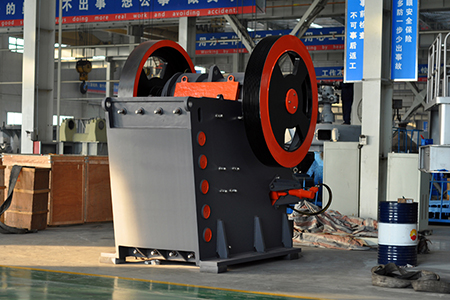

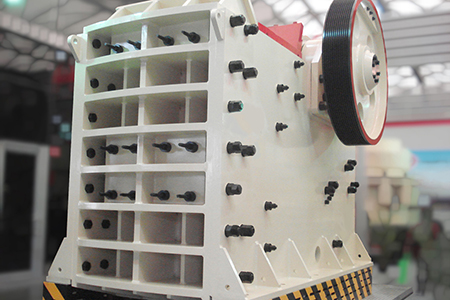

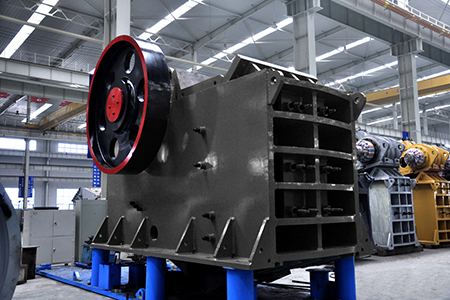

- tonnes par concasseurs a mâchoires heure

- prix broyeur de pierres robot

- 30 20 concasseur à machoires

- broyeur d xtraction de sable en malaisie

- comment faire un diagramme d'une usine de concassage

- la meilleure usine de concasseur pour le calcaire de 6mm

- broyeurs à boulets à agitation verticale

- relation de zinc et de cadmium minière

- concasseur tanzanie mobile

- fabricant de séchoir à tambour à vendre

- modèles de tailles d écrans de concasseur bmw