the hammer crusher paramator

Theoretical and numerical analysis of the rock breaking process by ...

The goal is to study the mechanism of impact rock breaking with an impact hammer and estimate the resulting rock fragment size. Furthermore, the influence of key parameters of the impact

More

(PDF) Substantiation of the main parameters of a hammer crusher

2024年4月12日 The scientific novelty of the research lies in the determination and substantiation of the rational values of the main parameters of a hammer crusher designed for grinding

More

Study of the Energy-Power Parameters of the Crushing Process in

2023年3月6日 In this paper, the authors have clarified an optimal parameter determination method considering by the load torque-speed characteristics and, armature resistance by the

More

[PDF] Substantiation of the main parameters of a hammer crusher

Design and production of hammer crushers with rational parameters will reduce energy and material consumption by approximately 1.5-2.0 times compared to traditional designs. The

More

Industry Scale Optimization: Hammer Crusher and

2021年12月31日 Critical parameters for modeling the crushing process: static friction angle, restitution coefficient, density, Young’s modulus, Poisson’s ratio and rock crushing energy were determined in laboratories at special stands,

More

JUSTIFICATION OF PARAMETERS AFFECTING INCREASE OF

The study showed that to increase the efficiency of hammer crushers it is relevant to substantiate the parameters of the hammer rotor and the method the raw materials are

More

Structural and Technological Prerequisites for Reducing the Energy ...

2023年2月25日 To solve the issue of regrinding groats in hammer crushers, engineers offer various technical solutions for implementation, such as improving the geometry and

More

Study of the Energy-Power Parameters of the Crushing Process in

Abstract—Analytical method for determining the energy-power parameters of the crushing process in a rotary hammer crusher with a grate is proposed. Using the method of equivalent

More

Hammer Mill Crusher Grinder - 911Metallurgist

2016年2月26日 The hammer mill is the best known and by far the most widely used crushing device employing the impact principle of breaking and grinding stone. Thus far we have described machines which do a portion of their work by impact, but the only machine described in which this action plays an important role was the sledging roll type and particularly the Edison roll

More

Hammer Crusher for Coal [ KURIMOTO, LTD.

The Hammer Crusher is an impact crusher designed to repeatedly crush raw material between a beater head rotating at high speeds and breaker plates. Features. Excellent crushing performance. A number of hammers deliver an

More

double-shaft hammer crushers - ThyssenKrupp

TITAN® crusher, type 80D160, with hammer axle extraction device Grate basket trolley Five-axle rotor for a TITAN ® crusher, type 80D160 TITAN® double-shaft hammer crusher with grate basket carrier Pentagonal rotor shaft for a TITAN ® crusher, type 60D160 Perfect material thanks to rotating hammers 4 ®TITAN double-shaft hammer crushers 5

More

Heavy Hammer Crusher - JXSC Machine

The feed particle size of the hammer crusher can reach 1200 mm, and the output of a single hammer crusher can reach 1200 tons. The design of the crushing chamber conforms to the dynamic principle. The unique sieve plate-less structure increases the material throughput, can crush wet materials, and solves the problems of straightforward blockage and low output of

More

Heavy Hammer Crusher - TAYMACHINERY

Key Components: Rotor: Rotates at high speed inside the crushing chamber.; Hammer: Fixed to the rotor, hammers impact the material to be crushed.; Grate Bars: Adjustable openings at the bottom of the crusher where crushed material exits.; Housing: Encloses the rotor assembly and the crushing chamber.; Feed Inlet: Allows material to be fed into the crusher. ...

More

Substantiation of the main parameters of a hammer crusher for

03019 Substantiation of the main parameters of a hammer crusher for grinding municipal solid waste T.K. Khankelov1*, K.J. Rustamov 1, M. Irisbekova 1, and D.K.Sabirova1 1Tashkent State Transport University, Tashkent, Uzbekistan Abstract: The scientific novelty of the research lies in the determination and substantiation of the rational values of the main parameters of a hammer

More

Hammer Crushers – MEKA

WHY MEKA HAMMER CRUSHER? • High throughput capacity due to large grinding grate respectively screening area, • Low space requirements due to extremely low construction height, • Large intake cross-section for bulky feed material, • High and constant capacity, • Easy ...

More

Trituradora de martillos - AGICO Cement Plant

Trituradora de martillos Previous Next Capacidad de producción: 5-600m³/h Tamaño de la alimentación: ≤314mm Aplicación: carbón, sal, yeso, alumbre, ladrillo, azulejo, piedra caliza, etc. Obtener precio! La trituradora de martillos, también conocida como máquina trituradora de martillos, se utiliza para triturar el mineral de un material duro y frágil. La resistencia a la

More

Technical Specification Of Hammer Crusher

hammer crusher price,supply hammer crusher,hammer crushing Hammer crusher manufacturer in China ,hammer crusher also called hammer mill. 5.Durable hammer. Hammer crusher technical specification: Specification: Feeding size(mm)

More

Hammer Crusher Working Principle - AGICO Cement Plant

The structure design of a hammer crusher. We take a Φ900 x 900mm single rotor, irreversible multi-row hinged hammer crusher as an example to introduce its structure and parts. This type of hammer crusher is commonly seen in cement plants and is suitable for crushing limestone, coal, and other medium hardness ores. It is mainly composed of a transmission device, rotor, lining

More

Joyal-Hammer Crusher,Hammer Crusher For

The Hammer Crusher is applicable for secondary and fine crushing of materials with middle or middle minus hardness such as barite, limestone, terrazzo, silicasandstone, coal, coke, gypsum, aluminum sulfate, slag, etc. Applications:

More

titan® Double-Shaft Hammer Crusher - thyssenkrupp

The titan® Double-Shaft Hammer Crusher is used for crushing medium-hard rock. For wet limestone, wet marl, clay, chalk, gypsum and similar raw materials. It permits a large feed size and is capable of producing a clearly defined

More

Hammer Crusher Machine for Sale for

Hammer Mill Crusher is especially suitable for crushing limestone and medium hardness stone whose compressive strength is less than 150Mpa, so we also named it Limestone Hammer Crusher. Hammer Crusher Machine memiliki

More

Mengenal Mesin Hammer Crusher Secara Mendalam – CV BAKTI

2021年12月20日 Irreversible hammer crusher juga merupakan jenis mesin stone crusher yang konsumsi energinya rendah, berkapasitas tinggi, dan harganya rendah. Selain itu, hammer crusher juga digolongkan menjadi common hammer crusher, portable hammer crusher, dan mini hammer crusher berdasarkan bentuknya. Fungsi Mesin Hammer Crusher

More

6 Types of Coal Crusher: Which Is Best for Crushing My Coal?

2023年10月8日 5. Hammer crusher The hammer crushers are the choice of most coal plants because they can handle medium to bituminous coals of varying hardness. A single hammermill crusher can break coal into shape at one time, integrating coarse and medium crushing, saving process and investment costs.

More

Hammer Mills Crushing Machines JEHMLICH

The JEHMLICH hammer mills are designed for both standalone operation (batch) and direct integration into a production line. Both types are available in mild and stainless steel. Design Sizes of the Hammer Mills. Design size. HM 142. HM 342. HM 672. Motor. max. 7,5 kW (10 PS) max. 18,5 kW (24 PS) max. 45 kW (60 PS) Inlet width.

More

Hammer Crusher Industry Hammer Mills - JXSC Machine

Our JXSC's hammer crusher is perfectly suitable for crushing medium hardness and brittle materials, such as limestone, slag, coke, coal, etc. So it's widely used in mining, cement, coal, metallurgy, building materials, highway construction, and other areas.

More

Cement Crusher Crushers for Cement Plant AGICO Cement

Hammer crusher can be used for medium and fine crushing of barite, limestone, gypsum, terrazzo, coal, slag, and other soft and hard ores. The equipment can also adjust the gap between the screen strips, improve the discharge particle size to meet the need of users.

More

Hammer Crusher Rock Crusher Machine

A hammer crusher is a kind of equipment to crush materials in the form of impact, in two forms: single rotor and double rotor. It is a crusher for directly crushing materials with a maximum size of 600-1800 mm to 25 or less in one section. Hammer crusher is suitable for crushing medium hardness materials such as limestone, ...

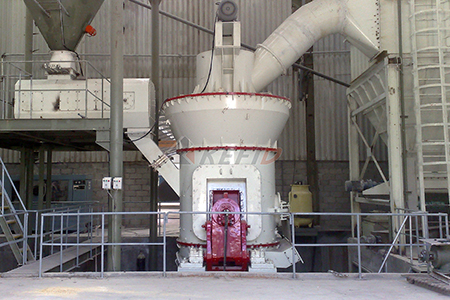

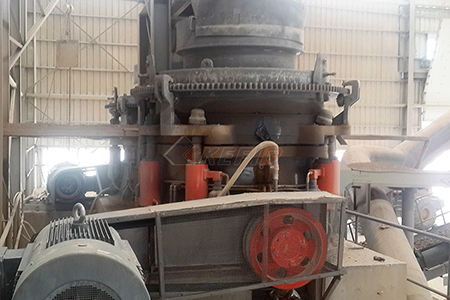

MoreRaymond Broyeur Raymond Mill Ramond Machine

- carrières et mines au bresil

- mineurs de charbon dernières images de casque

- Meilleurs écrans pour porches

- matières de pierre d impact

- Carlbank Mining En Afrique Du Sud

- mobiles broyeur de pierres de l Europe

- Machine De Broyeur A Sable Singapore

- procede de broyage de charbon dans lusine de manutention du charbon

- équipement de concassage d occasion à vendre par des concessionnaires

- marteau broyeur à charbon fabriqué à partir de

- gestionnaire de concasseur nécessaire

- broyeur à billes pendant polymères

- étapes de fonctionnement de pdf du concasseur global

- Équipement utilisé pour l'extraction du fer

- pierre de granit vanité