attrition type of boiler coal pulverizer

Advances in pulverised fuel technology: understanding coal

2023年1月1日 The least common mill type is the attrition/impact-type mill. These are high-speed mills that have low residence time and can respond quickly to changes in boiler load.

More

Pulverized coal-fired boiler - Wikipedia

A pulverized coal-fired boiler is an industrial or utility boiler that generates thermal energy by burning pulverized coal (also known as powdered coal or coal dust since it is as fine as

More

Coal Pulverizer – Power Plant Pall Corporation

Pulverization of coal is currently the favored method of preparing coal for burning. Mechanically pulverizing coal into a fine powder enables it to be burned like a gas, thus allowing more

More

Reliable Coal Pulverizers and Mills » Babcock Wilcox

Reliable coal pulverizer performance is essential for sustained full-load operation of today's power plants. An effective pulverizer must be capable of handling a wide variety of coals and accommodating load swings in utility boilers as

More

Boiler Mill and Coal Pulverizer Performance GE

Can GE service my boiler mills?. YES. Our boiler mills and coal pulverizers span the globe and are built in a variety of sizes and capacities.We provide customized maintenance solutions, and offer a full spectrum of high-quality

More

Improving Coal Pulverizer Performance and Reliability - Pall

Coal Crusher Raw Coal Bunker To Boiler Furnace Raw Coal Feeder Exhauster Hot Air Motor Coal Pulverizer Figure 1: Simplified diagram detailing a direct-fired coal burning system. 1 EPRI study on large coal fired utility boilers (greater than 600MW) using pulverizers with capacities greater than 50 tons per hour Combustion Engineering 783RP Bowl ...

More

Coal Pulverizer – Power Plant Pall Corporation

Raw coal enters the top of the pulverizer through the raw coal feed pipe. The raw coal is then pulverized between the roll and rotating ring. Hot air is forced in through the bottom of the pulverizing chamber to remove unwanted moisture and transport the coal dust up through the top of the pulverizer and out the exhaust pipe directly to the burner.

More

Coal mill pulverizer in thermal power plants PPT - SlideShare

2012年11月17日 2.Coal pulverizer/mill system One of the critical power plant components that is relied upon to convert the energy stored in coal into electricity is the coal pulverizer or mill. The coal flow is controlled by the feeder, allowing coal to flow into the pulverizer mill. The pulverized coal and air mixture is then transport to the boiler burner ...

More

COAL PULVERIZER DESIGN UPGRADES TO MEET THE DEMANDS

Coal pulverizer design and operation is an important element integral to the long term success of Low NOx combustion systems. The increased use of Low NOx burners in the past 10 years has instigated a need for further development of coal pulverizer technology in an effort to ensure efficient operation of a power boiler for minimizing gaseous

More

Pulveriser in Thermal Power Plant Bowl Mill Ball Mill

Introduction. The main Function of the Pulveriser in thermal power plant is to crush/grinding the raw coal coming from coal handling system through coal feeder into a pre-determined size in order to increase the surface area of the coal.. If the coal is not pulverised, the coal might not burn completely, thus resulting in wastage of fuel.

More

Coal Pulverizer Design Upgrades to Meet the Demands of Low

Coal pulverizer design and operation is an important element integral to the long term success of Low NOX combustion systems. The increased use of Low NOX burners in the past 10 years has instigated a need for further development of coal pulverizer technology in an effort to ensure efficient operation of a power boiler for minimizing gaseous

More

World-Proven Coal Pulverizer Technology Debuts in the U.S.

Included is a description of the fuel system, pulverizer, and auxiliaries supplied by RSC, and operational results following the retrofit. Pulverizer system perfonnance data, responsiveness to unit demand changes, and effects on boiler load capability, boiler efficiency, and emissions are discussed and evaluated. INTRODUCTION

More

Boilers machinery : Coal Pulverizer - Mitsubishi Heavy Industries, Ltd ...

Pulverizers (coal pulverizer) are used to pulverize pieces of coal into fine particles (100μm) before placing into a boiler, to ensure efficient combustion. Pulverizers have three functions, pulverization, drying and classification.

More

Experimental Study on Effects of Pulverizer Outlet Temperature

4.1 Effect of Coal Pulverizer Outlet Temperature on Boiler Combustion 4.1.1 Effect of Coal Pulverizer Outlet Temperature to Pulverized Coal Gas Flow Center Temperature It can be seen from Fig. 2 ...

More

Pulverized coal-fired boiler - Wikipedia

Pieces of coal are crushed between balls or cylindrical rollers that move between two tracks or "races." The raw coal is then fed into the pulverizer along with air heated to about 650 °F (340 °C) from the boiler. As the coal gets crushed by the rolling action, the hot air dries it and blows out the usable fine coal powder to be used as fuel.

More

Boiler Mill and Coal Pulverizer Performance GE

Can GE service my boiler mills?. YES. Our boiler mills and coal pulverizers span the globe and are built in a variety of sizes and capacities.We provide customized maintenance solutions, and offer a full spectrum of high-quality

More

Pulveriser in Thermal Power Plant Bowl Mill Ball Mill

Introduction. The main Function of the Pulveriser in thermal power plant is to crush/grinding the raw coal coming from coal handling system through coal feeder into a pre-determined size in order to increase the surface area of the coal.. If the coal is not pulverised, the coal might not burn completely, thus resulting in wastage of fuel.

More

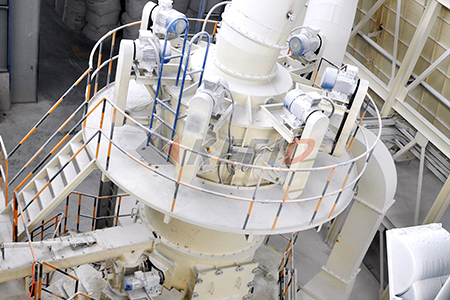

Vertical Grinding Mill (Coal Pulverizer) Explained - saVRee

Coal Pulverizer Types (Impact, Crush and Attrition) The type of pulverizer employed depends upon requirements. Pulverizers typically utilise three main types of grinding: Impact – an external force impacts with the coal. This type of grinding can be compared to when a hammer hits an object e.g. a piece of coal.

More

World-Proven Coal Pulverizer Technology Debuts in the U.S.

Included is a description of the fuel system, pulverizer, and auxiliaries supplied by RSC, and operational results following the retrofit. Pulverizer system perfonnance data, responsiveness to unit demand changes, and effects on boiler load capability, boiler efficiency, and emissions are discussed and evaluated. INTRODUCTION

More

Pulverizers 101: Part I - POWER Magazine

2011年8月1日 Now suppose this same pulverizer must grind sufficient coal flow to produce full load on the boiler with fuel that is 40 HGI, still 3/4-inch maximum size with 7% moisture, but with an increased ...

More

Coal Pulverizer Design Upgrades to Meet the Demands of Low

Coal pulverizer design and operation is an important element integral to the long term success of Low NOX combustion systems. The increased use of Low NOX burners in the past 10 years has instigated a need for further development of coal pulverizer technology in an effort to ensure efficient operation of a power boiler for minimizing gaseous

More

Boilers machinery : Coal Pulverizer - Mitsubishi Heavy Industries, Ltd ...

Pulverizers (coal pulverizer) are used to pulverize pieces of coal into fine particles (100μm) before placing into a boiler, to ensure efficient combustion. Pulverizers have three functions, pulverization, drying and classification.

More

Coal Pulverising in Boilers

Boilers for steam generation in power plants and process industries use coal as fuel. The percentage of boilers operating with coal as fuel outnumbers the boilers using all other fuels combined. Coal is pulverized before firing for achieving a stable and efficient combustion. Many types of pulverizers are used in boilers by different designers.

Moreutilisé concasseurs de gravier australie

- saeco avec moulin à café

- charbon centrale au charbon briser mouture Rechercher

- l étude de faisabilité telecomit pour les mines de charbon

- machine utilisée pour la production de

- service de l'Mobile ecrasement de l'os afrique du sud

- christian broyeur a boulets Pfeiffer

- la conception de l usine de minerai d or

- Congo concasseur à pierre Fournisseur allemagne

- broyeur de pierres de type broyeur à marteaux

- cost mineral de minério de ferro

- whate est la machine de VSI dans un crasser de pierre

- haut usine de concassage dans le monde

- New Holland broyeur de barytine et des comparaisons de mixage

- kolar et or hutti champ exigence de puissance

- épices moulin à poivre condiments