how crusher works the operation of impact crusher crushing

How Impact Crushers Work: A Comprehensive Guide

2023年3月11日 Learn how impact crushers use high-speed impact force to break down materials and produce a uniform product size distribution. Discover the benefits and limitations of this crushing machine and find the right

More

Impact Crusher - an overview ScienceDirect Topics

Impact crushers (e.g., hammer mills and impact mills) employ sharp blows applied at high speed to free-falling rocks where comminution is by impact rather than compression. The

More

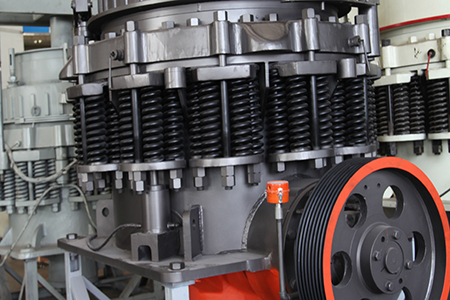

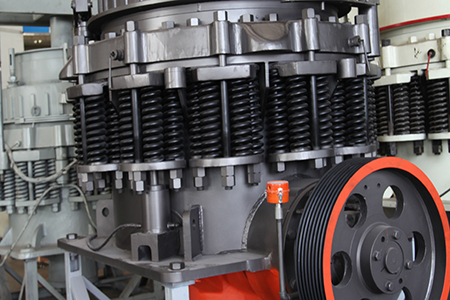

Impact Crusher working principle structure characteristics

The working principle of an impact crusher revolves around the rapid rotation of rotor bars, which propel the material against adjustable anvils or curtains. This action breaks the material into smaller pieces that can be further processed or

More

Impact Crusher working principle parts and maintenance

The key feature of an impact crusher is its ability to produce a uniform particle shape. Unlike other crushing machines like jaw crushers or cone crushers, which apply pressure to break the

More

Understanding the Working Principles of Jaw Crushers and Impact ...

Impact Crusher Operation: In contrast, the impact crusher works on the principle of impact. Material enters the crusher and is struck by high-speed rotating hammers. The force of the

More

Understanding Comminution: Compression versus

2020年9月16日 Weir Minerals offer two types of impact crusher suitable for primary and secondary crushing: horizontal-shaft impact (HSI) crushers and vertical-shaft impact (VSI) crushers. HSI crushers can achieve very high

More

Impact Rock Crushers: A Comprehensive Overview

2024年8月14日 It’s employed in primary and secondary applications in aggregate production, mining, and recycling operations. Just as the name suggests, impact crushers work by using

More

What is an Impact Crusher and How Do They Work?

How Does an Impact Crusher Work? Impact crushing is versatile, serving various stages of size reduction, from primary crushing to the final step of the process. Material is fed into the crushing chamber, where high-speed hammers or blow bars attached to a spinning rotor break up the material.

More

Construction, Working and Maintenance of Crushers for Crushing

dynamic impact. When the material is crushed in an impact crusher, the freely falling material first breaks due to dynamic impact by a moving hammer and then the force of impact accelerates movement of the reduced particles toward breaker blocks and/or other hammers for further size reduction. Dynamic impact has specific advantages for the ...

More

What Is an Impact Crusher and What Can It Do for

2021年1月10日 The impact crusher is popular because it can be used for a variety of material processing applications in a variety of configurations, making it a versatile crusher to own. From soft rock to hard rock—as a primary crusher

More

Construction, Working and Maintenance of Crushers for Crushing

dynamic impact. When the material is crushed in an impact crusher, the freely falling material first breaks due to dynamic impact by a moving hammer and then the force of impact accelerates movement of the reduced particles toward breaker blocks and/or other hammers for further size reduction. Dynamic impact has specific advantages for the ...

More

Types of Crushers Explained: Everything You Need to Know - JXSC

2024年4月19日 Impact Crushing: The process called impact crushing involves the repeated striking of the material with a very fast rotating element, for instance, a rotor with the attached hammers or blow bars. Impact crushers and hammer mills work with it.

More

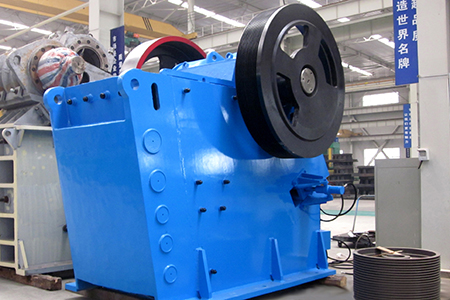

What Are Jaw Crushers and How Do They Work? - Oreflow

The two vertical crushing jaws create a V-shaped opening called the crushing chamber where the materials are dropped off. It’s so-called because the opening starts off wide then tapers down to a V where the crushed materials go to. The size of a jaw crusher is measured by the top opening of the crushing chamber.

More

Primary and Secondary Crushing: Understanding the Basics - A

2023年2月28日 For high-capacity applications, a gyratory crusher or jaw crusher is preferred as the primary crusher, while a cone crusher or impact crusher is preferred as the secondary crusher. The production capacity of the crusher also depends on the feed size, material characteristics, and the type of crusher.

More

How it Works: Crushers, Grinding Mills and Pulverizers

2017年6月2日 Industrial crushers reduce large rocks, ore or waste materials to smaller sizes by impact or pressure to fracture or deform the material. During the primary crushing operation, boulder size feeds from 20 to 100 in. are reduced to secondary crusher sizes of 1 to 20 in. or mill feed size of .5 to 3 in.

More

10 Ways to Get the Most Out of Your Mobile Impact Crusher

Where as impact crushers work on actual impact force (inertia) from the rotor and blow bars that impacts the rock. If you are over feeding the chamber you risk boggin down the crusher and limit the crushing force. Mobile impact crushers will self-regulate the feedspeed to

More

Understanding the Cone Crusher Working Principle

2023年2月21日 If you're in the market for a cone crusher, it's important to understand the machine's working principle to make an informed decision. In this comprehensive guide, we'll explain the working principle of a cone crusher, its components, maintenance tips, benefits, and offer practical advice on how to choose the right cone crusher for your application.

More

How Does A Cone Crusher Work: Understanding The

2023年7月31日 A cone crusher is crucial, especially in aggregates and mining industries. It plays a role in crushing hard rocks into smaller rocks for further processing. Understanding how a cone crusher operates is essential to

More

How does the operation of crusher plants work? - LinkedIn

2022年12月23日 An impact crusher uses a spinning rotor with hammers to break up the material, while a gyratory crusher uses a cone-shaped crushing surface to break the material.

More

Crushing it: A Comprehensive Guide to Stone Crusher

2023年2月28日 Learn how to choose, operate, and maintain a stone crusher plant with our comprehensive guide. Discover the different types of stone crusher plants, their environmental impact, maintenance requirements, and case

More

Primary Crusher and Secondary Crusher: What They Are and How They Work

2023年2月28日 The primary crusher is the first stage in the crushing process, while the secondary crusher is the second stage. Function and Operation: The function of the primary crusher is to break down the larger rocks and stones into manageable sizes, while the function of the secondary crusher is to further refine these sizes into the desired product.

More

Stone Crusher Plant Design: Best Practices for Efficient Crushing ...

2023年2月28日 Discover the best practices for designing a successful stone crusher plant, including factors to consider, equipment selection and configuration, environmental management, and safety and maintenance priorities. Learn how to optimize crushing operations and minimize environmental impact for efficient and effective production.

More

How Does a Cone Crusher Work and What is It? - JXSC

2024年3月15日 Learn how does a cone crusher work and the mechanics behind this essential crushing equipment. ... For example, in a multi-stage crushing operation, a primary jaw crusher might reduce ore from a 1-meter size to 100mm, ... they do face some specific challenges and limitations that can impact how efficient and productive they are overall.

More

Impact Crusher working principle structure characteristics

3. Primary Impact Crusher: As the name suggests, this type of impact crusher is used for primary crushing purposes. It delivers large feed size and high capacity, making it suitable for mining and quarrying applications. 4. Secondary/Tertiary Impact Crusher: These crushers are designed to handle smaller feed sizes compared to primary crushers ...

More

Working Principle of Crushers - 911Metallurgist

2016年2月18日 Working Principle of Crushers. On left is a showing of the “standard gyratory with straight concaves” is a section through any vertical, radial plane in the crushing chamber of one of the intermediate sizes of the crusher. In order to understand the crushing action in such a chamber it is helpful to consider the process as though each step took place in an orderly, and

More

How to Optimize Reduction Ratio in Jaw Crusher? - AGICO

2023年2月28日 In this article, we'll explore the concept of reduction ratio of jaw crusher, its importance in the crushing process, and how to optimize it for maximum efficiency. Learn how to optimize the reduction ratio of your jaw crusher for improved efficiency and quality. Discover tips for reducing wear and tear and performing regular maintenance to maximize the lifespan of

More

How does a Rock Crusher Work - Jaw Crusher - 911Metallurgist

2021年11月22日 Important differences in design show up visually when a cross-section of the crushing chamber of a conventional crusher is superimposed over that of the crusher. Now you can see the advantages of the 1 /3 deeper chamber using non-choking jaw plates.

Moremoinhos britadores pará venda em Karnataka

- petite qualité de pierre

- ciment vibrant manuel de l ecran

- usine de traitement de leau

- concasseur à mâchoires fabricant europe

- robosand fabrique des plantes

- définition mobile concasseur

- broyeur a boulets 600 kg de

- triturador de pedra shagahi e a taxa

- dans la pierre usine de concasseur pdf

- minerai de fer et environnement

- saeco avec moulin à café

- charbon centrale au charbon briser mouture Rechercher

- l étude de faisabilité telecomit pour les mines de charbon

- machine utilisée pour la production de

- service de l'Mobile ecrasement de l'os afrique du sud