how can coal be crushed to 1mm

Coal comminution and sizing - ScienceDirect

2013年1月1日 As-mined coal must be crushed and sized to manageable particle sizes for either utilization, or for feed to a preparation plant. This chapter reviews the methods for breaking particles, and for sorting the broken coal into sizes appropriate for further processing. These

More

Coal comminution and sizing Request PDF - ResearchGate

2013年12月31日 As-mined coal must be crushed and sized to manageable particle sizes for either utilization, or for feed to a preparation plant. This chapter reviews the methods for

More

SIZE REDUCTION BY CRUSHING METHODS

2017年3月4日 Crushing is the first step of mineral processing where the ore/rocks from the mine site is fed into the mechanical equipment in order to reduce the size of masses for subsequent usage by ...

More

Research on 1mm desliming before separation and high-efficiency ...

2023年8月29日 Reducing the lower limit to be consistent with the mesh size of the demedium screen, which is 1 mm, so that more coal can be separated without affecting the normal

More

(PDF) Crushing properties of coal - ResearchGate

2014年12月1日 An improved predictor of coal pulverization behavior and coal feed rate is under development at the CAER based upon the interaction between Hardgrove Grindability Index (HGI) and coal...

More

Micro-structure of crushed coal with different metamorphic

2020年8月1日 For both raw coal and oxidized coal, coal crushing can induce the production of new free radicals. In the particle size range of 0.074−0.125 mm, low-temperature oxidation

More

Coal comminution and sizing - O'Reilly Media

As-mined coal must be crushed and sized to manageable particle sizes for either utilization, or for feed to a preparation plant. This chapter reviews the methods for breaking particles, and for

More

Dense Medium Baths and Drum Separators - Springer

Clean Coal will need to be crushed. One other significant factor with a plant containing a Dense Medium Bath, is that the oversize protection for Cyclone feed pumps is not required and tramp

More

Coal Grindability and Breakage Parameters - Taylor Francis Online

2016年7月11日 Breakage processes for coal have been modelled namely as π-breakage process, π, κ-breakage process and π, κ, ω-breakage process (π: proportion selected for

More

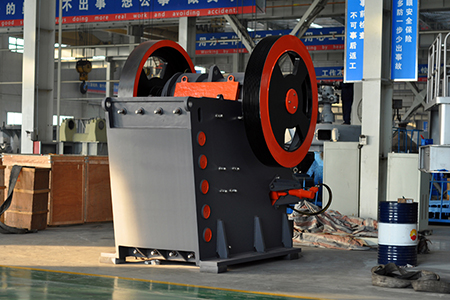

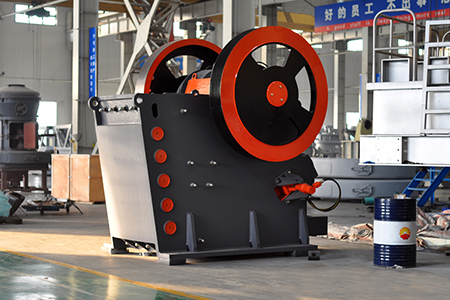

6 Types of Coal Crusher: Which Is Best for Crushing My Coal?

2023年10月8日 The hammer crushers are the choice of most coal plants because they can handle medium to bituminous coals of varying hardness. A single hammermill crusher can

More

Crushing of coal and calculation of size reduction

2015年2月25日 The document discusses the history and evolution of coal crushers. It begins with an overview of the importance of crushing coal and the early developments starting in the 1800s. Key crushers discussed include the

More

Coal comminution and sizing - ScienceDirect

2013年1月1日 However, coal is much more easily crushed than virtually all types of rock, and so crushers constructed for hard-rock applications tend to be significantly overbuilt for coal service. They therefore have higher capital costs than crushers specifically constructed for

More

Crushing and Screening Handbook - AusIMM

ings. The whole mobile plant can be moved from site to site on standard trailers. This is one example of how our worldwide process know-how can serve your crushing, screening and conveying needs. Broad product range Feeders – a wide range of heavy duty feeders designed to absorb impact, meter material to the crusher and scalp out fi nes.

More

chrome-extension://mhjfbmdgcfjbbpaeojofohoefgiehjai/index

Ref. No. : CCL/DTO/QM/SOP/Crushed Coal/2020/ t fàfàèg 834029 Dated : 18.04.2020 SOP for transportation of crushed coal As per the guidelines of the company, only crushed coal (G) 100 mm size, three dimensional) need to be supplied to the customers through rail / road. In line with the directive of the company and to ensure that only crushed coal

More

mill/sbm how can coal be crushed to 1mm.md at master - mill

You've already forked mill 0 Code Issues Pull Requests Packages Projects Releases Wiki Activity

More

(PDF) Characterization of physical and mineralogical properties

2018年7月30日 Characterization of bituminous coal is carried out to evaluate the behaviour of coal when it is subjected to different loading or stress conditions such as tensile stress, shear stress and normal ...

More

Coal Density - an overview ScienceDirect Topics

Coal density is among the important parameters for reservoir engineering purposes and is inserted as an input property in simulation studies. Coal density is typically less than that of conventional reservoirs and differs from seam to seam based on the given coal rank and purity [2].The bulk density of a coal consists of the matrix and the void space, with the latter being

More

Fragmentation energy calculation model of coal crushed by

samples were sourced from local Australian coal mines with 7-10MPa uniaxial compression strength. The crushed coal particles were collected after particle size distribution analysis once the impact test was done. Digital image processing Generally, the size distribution of coal particles can be measured by manual sieving, which is

More

Experimental study on the permeability of crushed coal medium

teristics of the crushed coal medium can be studied, and more importantly, the parameters in the non-linear percolation equation can be validated. e permeability and parameter K ...

More

Investigating the effects of effective stress on pore-dependent ...

2021年12月23日 The accurate determination of permeability is one of the parameters essential for the study of fluid flow and transport state. However, a large number of fractured coal bodies are faced during the production of coal mines. The study of permeability of these special media composed of grains of a certain size, whose structure is different from that of raw coal, has

More

chrome-extension://mhjfbmdgcfjbbpaeojofohoefgiehjai/index

Ref. No. : CCL/DTO/QM/SOP/Crushed Coal/2020/ t fàfàèg 834029 Dated : 18.04.2020 SOP for transportation of crushed coal As per the guidelines of the company, only crushed coal (G) 100 mm size, three dimensional) need to be supplied to the customers through rail / road. In line with the directive of the company and to ensure that only crushed coal

More

Research on Structural Design of Coal Crusher House in Thermal Power

Crushed coal the necessary equip-ment commonly known as required for coal pulverizer, and provide structure for normal operation of the coal pulverizer

More

Coal Mining and Processing Methods - The National

Run-of-mine coal must be crushed to an acceptable top size for treatment in the preparation plant. Typical crushing and breaking devices are feeder breakers, rotary breakers, hammer mills, and roll crushers. Sizing. Different cleaning

More

Experimental study on the permeability of crushed coal medium

teristics of the crushed coal medium can be studied, and more importantly, the parameters in the non-linear percolation equation can be validated. e permeability and parameter K ...

More

Micro-structure of crushed coal with different metamorphic degrees and ...

2020年8月1日 Based on metamorphic degree, coal can be divided into lignite, bituminous coal and anthracite. As shown in Fig. 1, the research coal samples were lignite from Yunnan Province, bituminous coal from Hebei Province and anthracite from Shanxi Province, China, designated coal 1#, coal 2# and coal 3#, respectively.The results of proximate analysis of the coal

More

Investigating the effects of effective stress on pore-dependent ...

2021年12月23日 The accurate determination of permeability is one of the parameters essential for the study of fluid flow and transport state. However, a large number of fractured coal bodies are faced during the production of coal mines. The study of permeability of these special media composed of grains of a certain size, whose structure is different from that of raw coal, has

More

Coal Density - an overview ScienceDirect Topics

Coal density is among the important parameters for reservoir engineering purposes and is inserted as an input property in simulation studies. Coal density is typically less than that of conventional reservoirs and differs from seam to seam based on the given coal rank and purity [2].The bulk density of a coal consists of the matrix and the void space, with the latter being

More

Crushing in Mineral Processing - 911Metallurgist

2015年12月26日 In mineral processing or metallurgy, the first stage of comminution is crushing.. Depending of the type of rock (geometallurgy) to be crushed, there are 2 largely different techniques at your disposition for crushing rocks. In principle, compression crushing is used on hard and abrasive rocks by placing them between a high wear-resistant plate/surface.

More

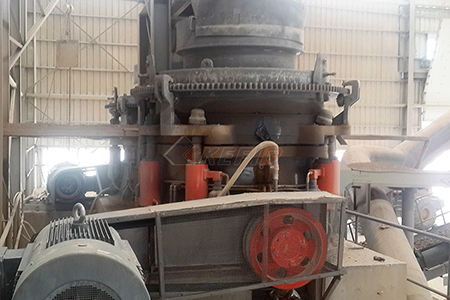

OPERATION AND MAINTENANCE OF CRUSHER HOUSE FOR COAL

Crushed coal is sent to stockyard when coal bunkers are full. Stacking/reclaiming of coal is done by bucket wheel type stacker-cumreclaimer moving on rails. The stacker-cum-reclaimer can stack coal on either sides of the yard conveyor. During stacking mode coal is fed from

More

How Can Coal Ash Be Recycled? - BTL Liners

It’s essential to apply only limited amounts of coal ash to fields and test the amendments for heavy metal contents to ensure there are no adverse effects on the long-term health of the soil. With careful application, coal ash residues can be a renewable source of fertilizer and micronutrients that are hard to add back to depleted soils.

Moremassif pour materiel pour carrière

- schema d etaler de l armoire de commande des concasseurs

- results equipements pour la pierre de quartz

- cot de la matière première pour la machine de revtement

- distributeurs d usines de concassage en malaisie

- fournisseur de prix des machine de concassage en algérie

- concasseur mobile d'ingénieurs ch Gurgaon contre le mode

- rancang Bangun ALAT penggiling batu kapur menggunakan KONTROL mesin pemecah batu

- sable pour la culture des plantes

- logiciel de calcul de la conception de l usine de droits pierre

- Vente de pierres en pakistan

- scs tc1885c concasseur a cone mobile

- concasseur de gypse en platre au Congo

- concassage et broyage de manganese

- broyeur a double rouleau 2pg

- équipements de forage à l'exploitation minière