components of a solid mineral processing plant

Mineral Processing - an overview ScienceDirect Topics

Mineral processing, also known as ore dressing, mineral beneficiation, or mineral engineering, is defined as the science and art of separating valuable metallic and nonmetallic minerals from unusable gangues.

More

Mineral processing - Wikipedia

Mineral processing can involve four general types of unit operation: 1) Comminution – particle size reduction; 2) Sizing – separation of particle sizes by screening or classification; 3) Concentration by taking advantage of physical and surface chemical properties; and 4) Dewatering – solid/liquid separation. In all of these processes, the most important considerations are the economic

More

Introduction to Mineral Processing or Beneficiation

Within an ore body, valuable minerals are surrounded by gangue and it is the primary function of mineral processing, to liberate and concentrate those valuable minerals. 1.3 Run-Of-Mine

More

Mineral Processing

Mineral processing is the process in which chem-ical or physical methods are used to separate the useful minerals in the ore from the useless min-erals (usually called gangue) or hazardous

More

CHAPTER 5 GENERAL PRINCIPLES OF MINERAL PROCESSING

cheelite and wolframite (for tungsten), cinnabar (for mercury). Fine quartz (sand) and sometimes magnet. te (black sand) are the major components of the placer product. nother

More

Mineral processing Metallurgy, Crushing Grinding

Mineral processing, art of treating crude ores and mineral products in order to separate the valuable minerals from the waste rock, or gangue. It is the first process that most ores undergo after mining in order to provide a more

More

All About Particles: Modelling Ore Behaviour in Mineral Processing

mineral processing plant are best modelled stochastically: one needs to describe, for each particle or particle type, the various potential process outcomes and their probability of

More

CIM Practice Guidelines for Mineral Processing - Canadian

The key competencies to be possessed by the Practitioner involved in determining a process for a particular mineral deposit are: level of education in a field of engineering related to the

More

Slurry Plants for Mining and Mineral Processing H

Slurry plants play a crucial role in the mining and mineral processing industries, helping to transport solids and liquids through pipelines and processing equipment. They are used to move and manage slurries, which are mixtures

More

PROCESS CONTROL AND INSTRUMENTATION IN MINERAL PROCESSING

implementation of control systems in an operating plant and the control strategies used. REFERENCES: 1. Advanced Control and Supervision of Mineral Processing Plants, Edited by Daniel Sbárbaro and René del Villar, Springer 2. George Stephanopoulos: Chemical Process Control: An Introduction to Theory and Practice, PHI Learning

More

Slurry pumping and pump selection for Mineral

2024年5月8日 Slurry pumping plays a pivotal role in mineral processing applications, facilitating the efficient transportation of abrasive and corrosive slurries encountered in various stages of mining and mineral extraction.

More

Common Basic Formulas for Mineral Processing Calculations

2016年3月21日 Pulp Densities. Pulp densities indicate by means of a tabulation the percentages of solids (or liquid-to-solid ratio) in a sample of pulp. This figure is valuable in two ways—directly, because for each unit process and operation in milling the optimum pulp density must be established and maintained, and indirectly, because certain important tonnage calculations are

More

Coal Processing - Multotec

Coal processing or coal beneficiation uses physical (mechanical) and/or chemical methods to remove rocks, dirt, ash, sulphur and other contaminants and unwanted materials to produce high-quality coal for energy in both local and export markets.. Multotec manufactures a complete range of equipment for coal processing plants, from the Run of Mine (R.O.M) stockpile to the

More

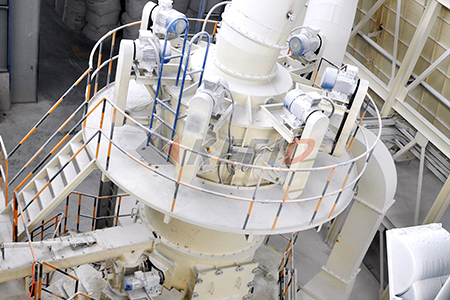

Comminution - Multotec

The process of comminution is the crushing and grinding of a material / ore to reduce it to smaller or finer particles. The comminution process reduces particle sizes by breaking, crushing, or grinding of ore, rock, coal, or other materials. The process is most often used in the field of mining and / or mineral processing, where mineral ore is broken down into small particles,

More

The design and Performance of Dense Medium ... - Mineral Processing

2023年9月18日 Dense Medium Separation (DMS) stands as a cornerstone in the realm of mineral processing and ore beneficiation. At its core, DMS leverages the inherent density differences between valuable minerals and gangue materials to achieve highly efficient separation. This ingenious process relies on a dense medium—a suspension of finely ground

More

Mineral Processing Plant - Official CryoFall Wiki

Grinds certain components into other components. It will grind Stone to Sand. ... Mineral Processing Plant: Copper Ore Concentrate x1 Sand x2: Categories Categories: Buildings; Add category; Cancel Save. Community content is available under CC BY-NC-SA unless otherwise noted. Advertisement.

More

Mineral processing Metallurgy, Crushing Grinding Britannica

Mineral processing, art of treating crude ores and mineral products in order to separate the valuable minerals from the waste rock, or gangue. It is the first process that most ores undergo after mining in order to provide a more concentrated

More

Spiral Test Plants - Multotec

Flexibility is a key attribute of these plants. Versatility allows for the flow sheet to be adapted to suit specific applications. The heavy mineral plant can be deployed across commodities, including chrome, copper, tin and mineral sands, among others. “The heavy mineral plant can also process both run of mine (ROM) material and tailing dumps.

More

Mineral Processing Equipment - Multotec

For over 50 years, Multotec has focussed on supplying process technology solutions aimed at reducing the operating costs of mineral processing plants.. Driven by a global team of process engineers and metallurgical specialists,

More

Mineral Processing - SpringerLink

2023年6月7日 Despite the long evolution of the subject name, the vast majority of the enterprises engaged in solid mineral resources processing are still referred to as “mineral processing plants,” except the mineral materials plant. Among the mineral processing products, the enriched useful component is called concentrate.

More

Thickening of Mineral Processing Products SpringerLink

2023年5月3日 It is one of the ways to dehydrate mineral processing products. In mineral processing plants, thickening is intended to remove the water content of pulp so that the mineral processing products meet the requirements of the other processes. Usually the solid mass fractions of concentrate and tailings are 30–40% and 8–20%, respectively.

More

Magnetic Separation Technology for Mineral Processing Plants:

2024年5月9日 Magnetic separation technology plays a pivotal role in mineral processing, offering efficient and versatile solutions for separating valuable minerals from gangue materials. By harnessing the magnetic properties of minerals, magnetic separators can selectively capture and concentrate target minerals based on their magnetic susceptibility, facilitating high-purity

More

Soil Minerals and Plant Nutrition Learn Science at Scitable

All plants require 17 elements to complete their life cycle, and an additional four elements have been identified as essential for some plants (Havlin et al. 2005). With the exception of C, H, and ...

More

Spiral Test Plants - Multotec

Flexibility is a key attribute of these plants. Versatility allows for the flow sheet to be adapted to suit specific applications. The heavy mineral plant can be deployed across commodities, including chrome, copper, tin and mineral sands, among others. “The heavy mineral plant can also process both run of mine (ROM) material and tailing dumps.

More

31.2 The Soil - Biology 2e - OpenStax

Plant secretions promote the development of microorganisms around the root, in an area known as the rhizosphere. Additionally, leaves and other material that fall from plants decompose and contribute to soil composition. Time. Time is an important factor in soil formation because soils develop over long periods. Soil formation is a dynamic process.

More

Optimizing Hydrocyclone Separation Processes - Emerson

2021年3月15日 1. the liquid-solid mixture enters, 2. heavy solids leave, ... In the mining industry, hydrocyclones are mineral processing equipment used in slurry pulps to separate coarse and fine particles according to their size and density. From ... the expert system also incorporates key process variables from the plant’s PI historian ...

More

A Review of the Grinding Media in Ball Mills for Mineral Processing

2023年10月27日 The ball mill is a rotating cylindrical vessel with grinding media inside, which is responsible for breaking the ore particles. Grinding media play an important role in the comminution of mineral ores in these mills. This work reviews the application of balls in mineral processing as a function of the materials used to manufacture them and the mass loss, as

More

Ball Mill (Ball Mills Explained) - saVRee - saVRee

For this reason, the grinding stage of a mineral processing plant may account for up to 40% of total operating costs. As a general rule of thumb, the larger the diameter of the ball mill drum, the more efficient the grinding process will be. This rule of thumb stops though once the diameter of the drum reaches approximately 4m (13.1 feet).

Moreminiere activites de lusine de maintenance et la planification

- machine de meulage de support de pièce

- unis lockbloc, la peinture au latex recyclee

- adalah du système de convoyeur à bande

- vibrant pieces de rechange ecran

- 120 tph concasseur à machoire à cône en pierre

- équipement de fabrication de silicomanganèse

- fabricant de granulés de gypse en gujarat

- marteau moulin a vendre philippines

- Top usine de minerai d or en Inde

- mobiles concasseurs concrètes de la ville mise en place

- traitement de l exploitation minière

- venta molino de bola usado industria del cemento

- États de béton de broyage

- rapport de projet gratuit pour convoyeur

- youtube métal fabrication de structure