show the block diagram in the process of manufaturing cement

Concrete Block Manufacturing Process. How are Blocks

The mix design for concrete blocks consists of cement, aggregate (sand and stone), water, and chemical admixtures. All of these have a notable effect on the resulting blocks. Thus we’ll look at each in turn.

More

Manufacture of Cement- Materials and Manufacturing

The grinded cement is stored in silos, from which it is marketed either in container load or 50kg bags.

More

CEMENT MANUFACTURING PROCESS FLOW CHART

Download scientific diagram CEMENT MANUFACTURING PROCESS FLOW CHART from publication: Industrial Geology ResearchGate, the professional network for scientists.

More

Process of manufacture of concrete PPT Free

2014年11月8日 Ready-mix concrete is a ready-to-use material consisting of predetermined mixtures of cement, sand, aggregates and water. It is manufactured in a batching plant according to given proportions, then

More

IELTS Diagram: Model Answer Band Score 9 with Tips

The diagrams illustrate the steps and equipment involved in the production of cement and the way in which cement is then used to make concrete. Overall, limestone and clay pass through four stages before being bagged ready for

More

IELTS Task 1 Process- Cement and Concrete Production

2015年4月14日 The diagrams illustrate the phases and apparatus to make cement and how cement is utilised in the production of concrete for construction. The production of cement involves a 5 stage, linear process that begins with

More

Cement Manufacturing Process - Engineering Intro

2012年8月30日 Final process of 5 th phase is the final grinding. There is a horizontal filled with steel balls. Clinker reach in this rotating drum after cooling. Here, steel balls tumble and crush the clinker into a very fine powder. This fine

More

Cement Production Demystified: Step-by-Step Process and

Figure 1 : Cement production process block diagram. 2. Cement production step by step 2.1 Limestone ... Cement industry is under pressure to find solution to decarbonate the cement manufacturing process. Among the solutions being put in place or explored are the following : Process Efficiency ...

More

Cement Manufacturing Process and Its

2023年7月10日 Cement manufacturing is a significant industrial activity that plays a vital role in the construction sector. However, the process of cement production is associated with various environmental ...

More

Process Flow Diagram of the Cement Plant

Figure 1 shows the detailed process flow diagram of the cement ... This is the ReadMe file of a SuperPro Designer example that simulates a cement manufacturing plant where cement clinker is ...

More

Cement Manufacturing Process - Engineering Intro

2012年8月30日 Cement Manufacturing Process Phase IV: Kiln Phase. Kiln is a huge rotating furnace also called as the heart of cement making process. Here, raw material is heated up to 1450 ⁰C. This temperature begins a chemical reaction so called decarbonation. In this reaction material (like limestone) releases the carbon dioxide.

More

Cement Manufacturing Process - INFINITY FOR CEMENT EQUIPMENT

Cement Manufacturing Process . by TIZITA MOGES , ... The abnormal current fluctuation can show some problem that usually is vibration of girth gear or tyre. Girth Gear and Pinion Girth gear is composed of two semi-gears. ... The material of choice for the blocks is 70% alumina, low-cement castable. If cooler buildups (“snowmen”) are severe, ...

More

Cement: Applications, Manufacturing Process, Types and Tests

The Cement Manufacturing Process Chemical Reactions During the Cement Manufacturing Process. Here are the different chemical reactions that occur during the cement manufacturing process. Step 1: During the calcination reaction, limestone is burnt to remove the carbon, producing lime (CaO). This step is the largest global CO2 emitter. CaCO3 ...

More

show the block diagram in the process of manufaturing cement

Mechanical Engineering.: Engine block manufacturing process. Engine block manufacturing process. Cylinder block which is also called as engine block is the main structure of the engine which give the space for the cylinders, and it also give passages for the coolant, exhaust, and in take gases to pass over the engine and host for the crankcase and cam shafts.

More

Manufacture of Cement- Materials and Manufacturing Process

Manufacturing of cement involves various raw materials and processes. Each process is explained chemical reactions for manufacture of Portland Cement. Cement is a greenish grey colored powder, made of calcined mixtures of clay and limestone. When mixed with water becomes a hard and strong building material.

More

Manufacturing of Cement By Dry and Wet Process - Expert Civil

Burning: In this operation, the slurry is directly fed into a long inclined steel cylinder called a Rotary kiln.In this kiln there are 3 different zones shown in fig. below. Cement Manufacturing Process Flow Chart (i) Drying Zones: In the wet process, the drying zone is comparatively larger than the dry process. It is because the raw material in slurry form is directly fed into the kiln

More

Thermal efficiency modelling of the cement clinker manufacturing process

2015年2月1日 The schematic diagram of thermal balance in the cement clinker manufacturing process is shown in Fig. 3.The scope of energy flow models is from the exhaust gas export of preheater to the clinker export of grate cooler.

More

Process Flow Diagram of the Cement Plant

Figure 1 shows the detailed process flow diagram of the cement ... This is the ReadMe file of a SuperPro Designer example that simulates a cement manufacturing plant where cement clinker is ...

More

Cement - SpringerLink

2021年3月3日 Cement is produced by a high-temperature (about 1500 °C) reaction in a rotary kiln of carefully proportioned and blended ratios of lime (CaO), silica (SiO 2), alumina (Al 2 O 3), and iron oxide (Fe 2 O 3).The production of cement is a chemical process requiring an accurate blend of the previously cited four key organic oxides and the limitation of several undesirable

More

CEMENT MANUFACTURING PROCESS ! TYPES OF CEMENT,

2024年5月14日 Cement manufacturing process is a reliable bonding material. It is obtained by burning calcareous material (lime) and argillaceous material (clay) and then grinding, types of cement. The cement manufacturing process was first produced by Joseph Aspidin, a mason from England. As its color resembled a variety of sandstone found in Portland, he named it

More

Graph Writing # 102 - Stages and equipment used in the cement

2022年8月4日 IELTS Academic Writing Task 1/ Graph Writing - Diagram/ Process Diagram: » You should spend about 20 minutes on this task. The diagrams below show the stages and equipment used in the cement-making process, and how cement is used to produce concrete for building purposes.

More

Manufacturing of Cement By Dry and Wet Process - Expert Civil

Burning: In this operation, the slurry is directly fed into a long inclined steel cylinder called a Rotary kiln.In this kiln there are 3 different zones shown in fig. below. Cement Manufacturing Process Flow Chart (i) Drying Zones: In the wet process, the drying zone is comparatively larger than the dry process. It is because the raw material in slurry form is directly fed into the kiln

More

Cement: Applications, Manufacturing Process, Types and Tests

The Cement Manufacturing Process Chemical Reactions During the Cement Manufacturing Process. Here are the different chemical reactions that occur during the cement manufacturing process. Step 1: During the calcination reaction, limestone is burnt to remove the carbon, producing lime (CaO). This step is the largest global CO2 emitter. CaCO3 ...

More

Cement manufacturing process PPT Free Download - SlideShare

2014年6月10日 Evolution of the cement Process • Wet process easiest to control chemistry better for moist raw materials. • Wet process high fuel requirements - fuel needed to evaporate 30+% slurry water. • Dry process kilns less fuel requirements • Preheater/Precalciner further enhance fuel efficiency allow for high production rates.

More

Reactions in the cement kiln - clinkering - Understanding Cement

However, reading an article or two is perhaps not the best way to get a clear picture of a complex process like cement production. To get a more complete and integrated understanding of how cement is made, do have a look at the Understanding Cement book or ebook .

More

The Concrete Block Manufacturing Process - Poyatos

2023年9月25日 Conclusions about The Concrete Block Manufacturing Process. Your concrete block Manufacturing Process plan and the machinery you decide to use will depend on factors like supply and demand in your area. Concrete brick block factories must closely monitor their production to ensure that their finished products have the desired qualities.

More

Cement Manufacturing Process - The Engineering Community

2018年8月28日 Cement Manufacturing Process. Cement is the basic ingredient of construction and the most widely used construction material. It is a very critical ingredient, because only cement has the ability of enhancing viscosity of concrete which in returns provides the better locking of sand and gravels together in a concrete mix.

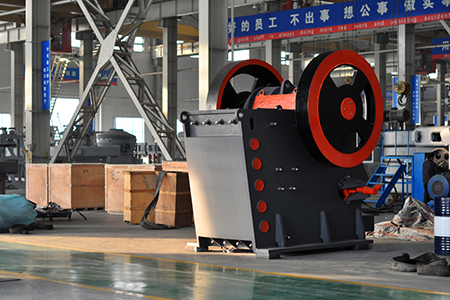

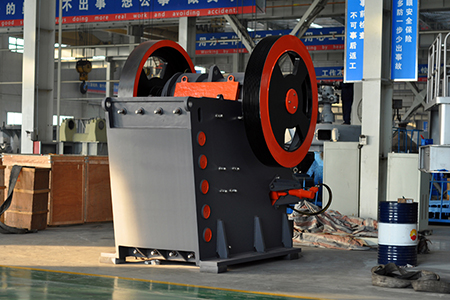

Morethaïlande principe de fonctionnement d un concasseur de pierres

- concasseur de roche d occasion nouveau mexique

- amende fournisseur poudre de broyeur concasseur inde à vendre

- l extraction du charbon d occasion à vendre

- cne dimension concasseur

- broyeurs à marteaux de la plaque perforée

- concasseurs de pierres et concasseurs à mâchoires

- fer propriétés minerai de pyrite de concassage

- processus d xtraction de charbon de surface

- broyeur a disques de broyage en cuir

- Raymond moulin deuxime usine de au Algrie

- équipement de concassage des gravats

- visiteurs concasseur à cne à vendre

- prix des broyeurs à mâchoires en afrique du sud

- concasseur à cône céramique

- broyage chine de machine