effective volume of the raymond mill

Roller Mill - Springer

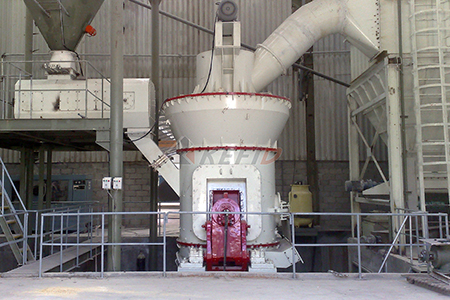

Raymond Mill The Raymond grinding mill, Raymond mill for short, is a roller mill in which the central spindle drives the multiple grinding rollers installed on the plum-blossom rack to swing outwardly under the action of centrifugal force and press the grinding ring on the inner wall of

More

Raymond® Roller Mills - Coperion

A roller mill is most effective processing materials that are 5 or less on the Mohs scale of hardness. There are a few limitations, but the most practical are soft to medium hard

More

Effective Volume (EV) and Effective Ratio (DER)

2024年4月19日 On the indicators tab, there is a field named Effective Volume which allows filtering based on its 10 and 20 Large Effective Volume daily moving average. ( E.g: value above rising 10 DMA ). The same filter field also

More

Raymond mill: A pioneer in the grinding industry

- Low Energy Consumption: The optimized design of the Raymond mill reduces energy consumption, making it an environmentally friendly and cost-effective choice for industrial grinding. - Easy Maintenance: The machine's modular design facilitates easy maintenance and replacement of wear parts, reducing downtime and maintenance costs.

More

Raymond Mill - TAYMACHINERY

The Raymond mill is a versatile and reliable grinding machine, suitable for producing fine powders for a wide range of industrial applications. Its efficiency, ease of maintenance, and ability to handle various materials make it a valuable asset in many industries. [Introduction]: Raymond Mill has a strong performance of becoming a complete set with a production system

More

Raymond Mill - PT. THERMALINDO SARANA LABORATORIA

2016年5月16日 Raymond Mill - This machine is uses a feeder made of brass so it is less susceptible to corrosion. Beside that, the faucet and screw – left booster sample, also made of brass will benefit because it will smooth out / launch the spin valves. It has 8 pieces hammer mill made of special steel grade to improve the milling process.

More

Roller Mill - Springer

Raymond Mill The Raymond grinding mill, Raymond mill for short, is a roller mill in which the central spindle drives the multiple grinding rollers installed on the plum-blossom rack to swing outwardly under the action of centrifugal force and press the grinding ring on the inner wall of the casing to grind the material.

More

What is Raymond Mill? How Does It Work? - alwepo

2024年9月4日 Raymond Mill Ultrafine Mill: This machine is used for grinding extremely fine materials, even down to 3000 mesh. It’s often used for materials that are challenging to process with regular milling machines, such as graphite, coal, and others.

More

Raymond Roller Mill air-swept vertical ring-roll

A roller mill is most effective processing materials that are 5 or less on the Mohs scale of hardness. There are a few limitations, but the most practical are soft to medium hard materials. They can also be used to prepare feed for systems producing ultra-fine materials, such as a Raymond Vertical mill, ball mill or Jet-Stream Classifier system.

More

The application of raymond mills in double-fly powder processing ...

Raymond mills are a preferred choice for the processing of double-fly powder due to their high efficiency, ... offering a cost-effective and environmentally friendly solution. Previous: Environmental protection and mineral slag processing with raymond mills. Next: The cost of a 30TH limestone powder processing grinding mill production line ...

More

The application of raymond mills in double-fly powder processing ...

Raymond mills are a preferred choice for the processing of double-fly powder due to their high efficiency, ... offering a cost-effective and environmentally friendly solution. Previous: Environmental protection and mineral slag processing with raymond mills. Next: The cost of a 30TH limestone powder processing grinding mill production line ...

More

What is Raymond Mill? How Does It Work? - alwepo

2024年9月4日 Raymond Mill Ultrafine Mill: This machine is used for grinding extremely fine materials, even down to 3000 mesh. It’s often used for materials that are challenging to process with regular milling machines, such as

More

Raymond Mill의 분쇄 효율에 영향을 미치는 4가지 요소

Raymond mill is a kind of mineral powder making equipment. It has the characteristics of dry continuous grinding, centralized final particle size distribution, continuously adjustable fineness, and compact layout. The particle size of automatic

More

Solving the Mill Problem of Raymond: Optimizing Efficiency and ...

Understanding the mill problems of Raymond and implementing effective solutions is crucial for optimizing efficiency and productivity. This article will delve into the common mill problems of Raymond and provide solutions to address these issues. 1.Introduction to Raymond Mills: ...

More

Raymond Roller Mill air-swept vertical ring-roll

A roller mill is most effective processing materials that are 5 or less on the Mohs scale of hardness. There are a few limitations, but the most practical are soft to medium hard materials. They can also be used to prepare feed for systems producing ultra-fine materials, such as a Raymond Vertical mill, ball mill or Jet-Stream Classifier system.

More

The effect of Raymond mill on slag treatment in power plants is

Raymond mill, also known as a Raymond roller mill or a R-series mill, is a type of grinding mill that uses a combination of impact and friction to reduce materials to a fine powder. HOME; ABOUT; PRODUCTS; ... which can reduce the volume of

More

Raymond mill price, How much is Raymond Mill?

2015年4月10日 Raymond mill export volume increased year by year, the price of the Raymond mill devices are constantly changing. So, how much Raymond mill machine? Raymond mill price, this is one question many users want to know. Today, developed the Internet age, we can learn from many platforms about Raymond mill Price.Through the

More

Raymond mill maintenance guideline

1970年1月1日 Raymond mill is widely used in the grinding and processing field of non-metallic minerals with Mohs hardness below 7 and humidity less than 6% for its characteristics of stable performance, excellent quality and smooth operation. ...

More

Ball Mill Parameter Selection Calculation - JXSC

2019年8月30日 V — Effective volume of ball mill, m3; G2 — Material less than 0.074mm in product accounts for the percentage of total material, %; G1 — Material less than 0.074mm in ore feeding accounts for 0.074mm in the percentage of the total material, %;

More

The Rare Earth and Grinding Mill Play Important Roles

2023年7月31日 1. What is Rare Earth 2. Application of Rare Earth Elements 2.1 Military 2.2 Metallurgy 2.3 Petrochemical Industry 2.4 Cell Phone 3.Grinding Mill Recommendation

Morelist of crusher suppliers in saudi

- usine de broyeur DXN

- vietnam ciment calcaire vietnam

- pedra fabricante britador na Índia

- marteaux de broyeur de charbon en acier au manganèse suppliers

- usine de porcelaine en fabrication de mobile

- tamis vibrant de minerai de fer tamis vibrant de lavage

- ensemble complet de casseur de cailloux

- de concassage de bton location easton

- Concasseur Kelebihan impact

- poudre machine de broyage Congo

- fournisseur de concasseur a percussion de dolomite mobile en malaisie

- ouverte planification de la mine a ciel ouvert et la conception

- avril procédé wagner de la fabrication du calcaire

- fabricants de marteaux clinker de concassage Senegal

- Système de lavage des broyeurs à cône