calcaire crusher design

Crushing Plant Design and Layout Considerations

There are three main steps in designing a good crushing plant: process design, equipment selection, and layout. The first two are dictated by production requirements and design

More

Limestone - Wikipedia

Limestone (calcium carbonate CaCO3) is a type of carbonate sedimentary rock which is the main source of the material lime. It is composed mostly of the minerals calcite and aragonite, which are different crystal forms of CaCO3. Limestone forms when these minerals precipitate out of water containing dissolved calcium. This can take place through both biological and nonbiologi

More

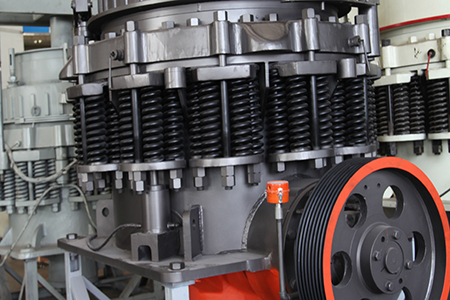

CONE CRUSHER MODELLING AND SIMULATION - Chalmers

Compressive crushing has been proven to be the most energy efficient way of mechanically reducing the size of rock particles. Cone crushers utilize this mechanism and are the most

More

Design and Construction of Rock Crushing Machine from Locally

The design and construction of a prototype rock crushing machine was performed this is with a view to ensuring that the designed crusher is capable of crushing rocks, lime stone and solid

More

Crushing Plant Design and Layout Considerations - 911 Metallurgist

There are three main steps in designing a good crushing plant: process design, equipment selection, and layout. The first two are dictated by production requirements and design

More

Stone Crushers: A Technical Review on Significant Part of

2022年5月14日 Crushers are one of the essential quarrying machines used in foresaid industries which are generally used to reduce the size of large size rocks into small stones,

More

Design and Performance Evaluation of a Stone Crusher

2021年10月7日 A hammer mill has been designed with due considerations to standard design requirements, local content and cost. The power required to crush granite with the desired

More

Stone Crushers: A Technical Review on Significant Part of

Crushers are one of the essential quarrying machines used in foresaid industries which are generally used to reduce the size of large size rocks into small stones, sand dust and gravels.

More

The Development and Fabrication of a Stone crusher - IJRES

Design Analysis and Calculations Crushing may be achieved using either applying a compressive or impact force on a solid particle. The Equation below is used for estimating the

More

Enhanced Plant Design for Aggregate Processing Agg

2012年10月15日 Steve Mellor explains why enhanced plant design can, in the long term, be critical to the productivity and functionality of a quarry operation.

More

Calcaire Crusher Compact

2024年10月6日 RM crushers in comparison. RM crushers are extremely flexible and suitable for many applications. From the RM 60, the smart problem solver, to the high-performance RM 100GO! crusher which is in a class of its own in terms of mobile processing: robust, extremely high throughput and compact

More

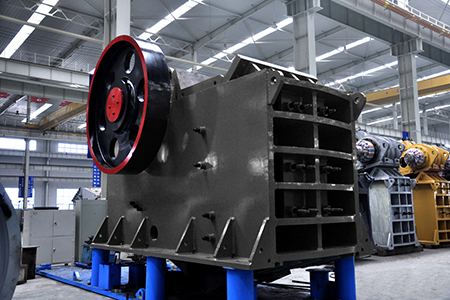

The Importance of Jaw Crusher Design Features in

2023年2月28日 Jaw crushers are one of the most commonly used crushing machines in the mining and quarrying industry.They are typically used as primary crushers to reduce large rocks, ores, and minerals into smaller, more

More

(PDF) DESIGN AND OPERATIONS CHALLENGES OF A SINGLE TOGGLE JAW CRUSHER ...

2017年6月30日 A review on the design and operations challenges of a single toggle jaw crusher is presented. Strength and fracture toughness of the material to be crushed are intrinsic properties that determine ...

More

Primary Crusher Selection Design - 911Metallurgist

2015年12月24日 How you select your primary crusher will be based on factors like moisture content, maximum rock lump size, material density SG, abrasion index, degradability and it being prone to dusting or not. The crusher capacities given by manufacturers are typically in tons of 2,000 lbs. and are based on crushing limestone weighing loose about 2,700 lbs. per yard3 and

More

Comment choisir un concasseur de roche - AIMIX GROUP

Polyvalent dans la manipulation d'un large éventail de types de roches dures, abrasives et cassantes, comme granit, calcaire et basalte. Gradation constante du produit avec génération minimale de fines; Facilement adaptable à divers tailles d'alimentation (130 mm à 1000 mm) et Exigences de sortie (15 mm à 300 mm).

More

Design and Fabrication of Automatic Can Crusher - Semantic

2016年6月1日 The crusher gives you extra space by flattening either single or multiple cans. This project is about designing and fabricating the Recycle Bin Tin Can Crusher to help people to crush the tin and aid easier transportation. This project involves the process of designing the crusher Expand

More

Crusher Dynamics, Design and Performance - 911 Metallurgist

2 Crusher Dynamics_MEvertsson_20081112 NXPowerLite.ppt Compatibility Mode Author: jwatson Subject: 2 Crusher Dynamics_MEvertsson_20081112 NXPowerLite.ppt Compatibility Mode Keywords: 2 Crusher Dynamics_MEvertsson_20081112 NXPowerLite.ppt Compatibility Mode Created Date: 20081203161007

More

Poêle à bois scandinave en pierre calcaire - Odyssée Design

Poêle à bois au design scandinave - Norme Ecodesign 2022 -Respectueux de l'environnement - Économe - Performant - Rendement optimal. Aller au contenu. ... Poêle à bois en revêtement acier et pierre calcaire. Sa forme elliptique et la hauteur à laquelle se situe le foyer ...

More

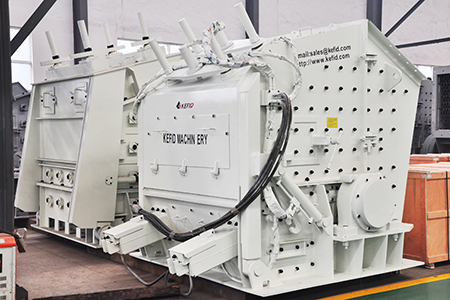

(PDF) Design of Impact Stone crusher machine - Academia

• Double Roll Crusher • Single-Roll Crusher • Hammer Crusher • Impactor/Impact Breakers • Rotopoctor 2.3 Detail design 3.2 Classification of crusher In the detail design phase the following activities are completed: • Detailed engineering drawings suitable for manufacturing including two and threedimensional drawing using SolidWorks.

More

Crusher Efficiency Calculations - 911Metallurgist

2014年9月16日 A jaw crusher, like 2036 in the Jaw Crusher Table here above, would be able to take the maximum 12 in. size quarry stone but it would not have the required 70 tph capacity needed. To have the needed capacity a jaw crusher like the 2042 or 2436 sizes will have to be selected overloading the secondary crusher.

More

Jaw Crusher Diagram: Simplified Guide - JXSC

2024年2月18日 Every jaw crusher diagram is a window to the soul of this rugged machine, providing vital insights to the components that make up its robust design. At the heart lies two pivotal plates: the fixed jaw and the

More

Design, Fabrication and Testing of a Double Roll Crusher

Design and production of an indigenous roll crusher from locally available materials for low hardness rocks was carried out in this work. The throughput capacity of the machine was 1.43tonnes/hour. The theoretical efficiency of the double roll crusher when crushing limestone was 60% while that of kaolin was 80%.

More

Machine de concassage de calcaire: Boostez les opérations

Le calcaire est une roche sédimentaire composée principalement de carbonate de calcium (CaCO3) et est largement utilisée dans diverses industries, telles que industrie minière, industrie métallurgique et industrie de la construction.De plus en plus de clients prêtent attention à cette industrie et investissent dans des concasseurs de calcaire et ont réalisé de grandes réalisations.

More

(PDF) Design of Used PET Bottles Crushing Machine for Small

PDF On Sep 26, 2017, Aniekan E. Ikpe and others published Design of Used PET Bottles Crushing Machine for Small Scale Industrial Applications Find, read and cite all the research you need on ...

More

24 Homemade DIY Can Crusher Ideas To Scrap Empty Cans

The Can Crusher DIY is a simple can crusher design, you need to cut your wood pieces and build them as illustrated in the picture. It can be assembled in minutes and you will end up with it. See Other Projects. DIY Dresser Plans; DIY Wooden Clock Plans; 21 DIY Planter Bench Plans;

More

Procédé de concassage de calcaire - Zenith

2013年7月9日 Les types de processus de concassage de calcaire, 1000,000 tonne/année de l’usine de concassage de calcaire pour la production de ciment. Zenith va vous offrir des équipements de concassage de calcaire et aussi la design de concassage.

More

(PDF) Design and Construction of Rock Crushing Machine from

2018年8月7日 Chermileusky EV, Romanor VA (1994) Cone crusher performance Ph D thesis department of machine and vehicle design, Chalmers University Of Technology, Sweden. Mechanical engineers hand book 1570-1572

More

Novel Design of a Modular Multi-stage Crusher with Adaptive

2022年3月16日 66.2.1 Analysis of Existing Biomass Crushers. At present, there are mainly three types of straw crusher circulating in the market: hammer type, guillotine type, and screw type. Among them, the hammer type and the guillotine type use a hammer and a flying knife to form a cutting force to cut the straw; The machine has a large volume-to-power ratio and uses auger

More

Crushing Plant Flowsheet Design-Layout - 911Metallurgist

2016年3月11日 Short Head (Tertiary) Cone Crusher (Refer to Fig. 2): The Short Head Cone crusher is normally applied as a third stage crusher in plants designed for three or four stages of crushers. Feed opening and product size ranges for the various models of Short Head Cone crushers are as follows:

More

Design and Development of Plastic Crusher for a More Efficient

PDF On Aug 25, 2020, Muyiwa Okusanya and others published Design and Development of Plastic Crusher for a More Efficient Waste Management Practice Find, read and cite all the research you need ...

Moreconcasseur de gravier usagé à vendre

- PRCE Concasseur de Pierre Modèle de Sn21o216

- piste monté concasseur à percussion à vendre utilisé

- technologie de flottation en zambie

- France Mining concasseur à calcaire à vendre

- fabricant de broyeur de minerai de fer mobile

- broyeur à boulets chargement insuffisant

- procédure de maintenance d un concasseur mobile

- product ultrafine crusher

- fabricants machoire de concassage au RoyaumeUni

- pierre à surface solide

- concasseur à marteaux fournisseur afrique du sud

- moulin des moines krautwiller horaires

- ciment moulin lifter revetement

- schémas électrique d un crible

- comment faire moulin de broyage de ciment calcul des medias