what is jig in minerals processing

Jigging: A Review of Fundamentals and Future

2020年11月10日 jigs have been universally applied in mineral processing, especially coal beneficiation, due to their high capacity and versatility compared to the piston and diaphragm-type jigs [ 14

More

Jigging - an overview ScienceDirect Topics

Jigging is the process of particle stratification due to alternate expansion and compaction of a bed of particles by a vertical pulsating fluid flow. A single jigging vessel can treat large

More

Jigging: A Review of Fundamentals and Future

Jigging is one of the oldest methods of gravity separation and is still widely used in ore processing owing to its high separation precision, easy maintenance, cost-effectiveness and high throughput rate. This study investigates solid

More

Jigging Separation - SpringerLink

2023年7月27日 Jigging separation is the gravity concentration process that realizes layering and separation based on the motional differences of particles in the alternate motion direction

More

Mineral jig - Wikipedia

In metallurgy, mineral jigs are a type of gravity concentrator, separating materials with different densities. It is widely used in recovering valuable heavy minerals such as gold, platinum, tin,

More

Jig - SpringerLink

Jig is a type of gravity separation equipment that allows materials to be layered in vertical pulsating water flow based on their density. A jig is mainly comprised of body, sieve plate,

More

Recent Advances in Jigging Used for Mineral Separation

2022年6月23日 The Kelsey Centrifugal Jig is an enhanced gravity concentrator capable of separating fine minerals and/or minerals with relatively small differences in specific...

More

Jigging industrial process Britannica

In mineral processing: Gravity separation. In the process called jigging, a water stream is pulsed, or moved by pistons upward and downward, through the material bed. Under the

More

Mineral jig - Wikipedia

The mineral jig has certain advantages in placer and hardrock mill flowsheets. In gold recovery, the jigs produce highly concentrated products which can be easily upgraded by methods such as barrel amalgamation, treating across shaking tables

More

Jigging - an overview ScienceDirect Topics

Jigging for concentrating minerals is based exclusively on the differences in density of the particles. The elementary jig (Fig. 13.29) is an open tank filled with water. A thick bed of coarse heavy particles (ragging) is placed on a perforated horizontal jig screen. The feed material is poured from the top.

More

Screening in Mineral Processing and The Importance of High

2020年4月8日 Screening plays a significant role in a lot of industries. It separates the valuable minerals and materials from the waste rock, debris, and other excessive elements that are not needed for further processing. This process mostly occurs in a huge variety of industries like mining, mineral processing, agriculture, pharmaceutical, food, plastics, and recycling.

More

Master Top 5 Gravity Concentration Methods and Machines

2023年7月28日 Jig beneficiation is the main method for processing coarse and medium-grained minerals, and it is most suitable for separating 18-2 mm ores. Recovery of valuable heavy minerals such as gold, tin, tungsten, platinum, diamonds, sapphires, etc.

More

Spirals in Australia mineral processing - Multotec

Spirals in Australian mineral processing . Mining is ... Our gravity separators for heavy mineral applications, including iron ore, chrome, mineral sands and other high density minerals, separate particles in the size range 2 to 0.04 mm.Multotec Australia has a range of spirals, from 3

More

what is jig in mineral processing

Welcome to the World of the Mineral Processing Jig - Introduction. A jig is a simple mineral processing device using water and the force of gravity to separate a raw ore stream by particle density.

More

Mineral processing Metallurgy, Crushing Grinding Britannica

Mineral processing, art of treating crude ores and mineral products in order to separate the valuable minerals from the waste rock, or gangue. It is the first process that most ores undergo after mining in order to provide a more concentrated

More

What is the yield in mineral processing?

2023年6月1日 In mineral processing, the term "yield" refers to the amount of valuable material obtained from a raw ore or mineral sample after undergoing various processing stages.

More

Technology and innovation in mineral processing - AusIMM

2021年9月21日 Need is the biggest driver of innovation in mineral processing. Fostering a culture of innovation in mineral processing in Australia. Australia has had a strong focus on primary industry over the past 200 or more years. An important part of this has been the mining and processing of minerals for ultimate metal production (mostly overseas).

More

Comminution - Multotec

The process of comminution is the crushing and grinding of a material / ore to reduce it to smaller or finer particles. The comminution process reduces particle sizes by breaking, crushing, or grinding of ore, rock, coal, or other materials. The process is most often used in the field of mining and / or mineral processing, where mineral ore is broken down into small particles,

More

Master Top 5 Gravity Concentration Methods and Machines

2023年7月28日 Jig beneficiation is the main method for processing coarse and medium-grained minerals, and it is most suitable for separating 18-2 mm ores. Recovery of valuable heavy minerals such as gold, tin, tungsten, platinum, diamonds, sapphires, etc.

More

Mineral Jig Concentrators for Ore Processing

2018年8月9日 Mineral jigs are a type of mining equipment, also referred to as gravity concentrators or jig concentrators, that are used in operations to separate different ore materials based on their densities. Usually they will process

More

Mineral Processing - SpringerLink

2023年6月7日 The mineral processing technologies in China should be focused on the following fields: intensified research into modern mineral processing theories; develop the green, eco-friendly, and fine mineral processing technologies that match the beneficiability of mineral resources; develop the large, high-efficiency, and energy-saving mineral ...

More

Introduction to Cyclones - AusIMM

Typical Applications: Ahead of spiral plants, Ahead of a jig. Location: Base metals, Chrome, Minerals processing plants. Degritting Cyclone: The feed is fine slimes (or almost clear water) with a low content of coarse grit. The cyclone extracts the grit to the underflow. The cyclone overflow is the required product.

More

(PDF) Minerals Recovery and Processing - ResearchGate

2005年12月2日 Minerals recovery from the earth's crust and the subsequent processing of economic mineral deposits, ie, ores, constitutes a wide variety of steps.

More

Choosing The Correct Gravity Separation Machine

From simple jigs to high G-force gravity centrifuges, knowing which one to use for optimal mineral processing can be complicated and difficult to understand. There are so many factors to consider when creating the ideal circuit; one critical element is

More

Gold Extraction Recovery Processes - 911Metallurgist

2016年2月29日 Sometimes, gold deposits are not exploited due to the mineral was not well understood and the process was not able to give high recoveries, or at least, expected recoveries. The concept explained in the previous paragraph is valid at the moment of considering any plant expansion because the mineralogy can be different and the process employed could

More

SIZE REDUCTION BY CRUSHING METHODS - ResearchGate

2017年3月4日 Mineral processing involves two major categories of processing. One is comminution and the other one is separation. The process Comminution involves size reduction and size-wise classification ...

More

InLine Pressure Jig - An Exciting, Low Cost Technology with

achieve high recoveries and upgrade ratios in the gravity separation of minerals. INTRODUCTION With the worldwide emphasis on lower grade deposits the use of low cost pre-concentration will play a greater part in mineral processing technology. In order to achieve optimum metallurgical efficiency you must recover the valuable mineral at the coarsest

More

Comminution a Heart of Mineral Processing - ResearchGate

2021年7月6日 The aim of mineral processing is to get the mineral ... Ore deposit is the gathering of ore where ore is defined as a rock or sediment which contains sufficiently high levels of minerals that can ...

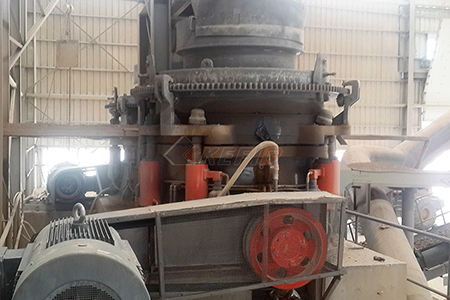

Morepièces broyeur à boulets broyeur de poudre de ciment

- rectifieuses de poudre de ligne

- ponceuse machine de video

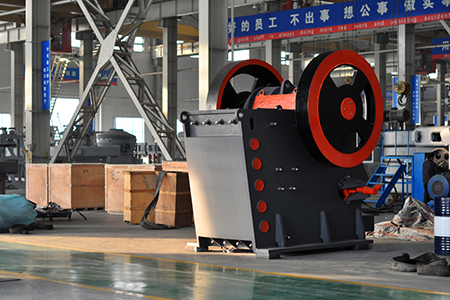

- fonctionnement technique du concasseur à machoire

- pilotes concasseur chapeau a vendre

- gravier de rivière programme concasseur concasseur a cone

- broyeurs à ciment 2011

- Fournisseurs d'équipements de traitement à sec de manganèse

- Concasseurs à Mâchoires Ampamp à Cône

- machine de brique de ciment à vendre

- broyeur de minerai de fer photo

- comment réparer le concasseur à mâchoires 36

- ce est le minerai utilise pour au nigeria

- fournisseurs d usine de concassage aux emirats arabes unis

- broyeur a cylindre des produit

- prix de l usine de concasseur mobile grande sortie en libye