china iron ore sintering systems

Recent progress in sustainable and energy-efficient technologies

2020年10月1日 Chinese government data indicate that iron ore sinter producers will be able to save 0.42 million tons of standard coal [21] and cut CO 2 emissions per annum by

More

Recent Advances and Research Status in Energy Conservation of

2017年9月19日 This review focuses on the recent progress and research status of energy conservation in iron ore sintering in China. The application of these technologies has greatly

More

Research Progress of Intelligent Ore Blending Model

2023年2月13日 The intelligent ore blending model with an intelligent algorithm as the core is studied. It has a decisive influence on the development of China’s steel industry. This paper first analyzes the current situation of iron ore

More

Iron ores matching analysis and optimization for iron-making

2017年8月8日 Science China Technological Sciences - An optimization model for iron-making system covering sinter matching process to blast furnace process is established, in which the

More

A novel blending principle and optimization model for low-carbon

2019年10月1日 Introduction. The crude steel production of China has exceeded 800 million tons since 2014, which accounting for about 50% of world's production. The convention blast

More

Application of deep learning in iron ore sintering process: a review

2024年3月16日 The sintering process is an intricate system with a protracted process flow. The steps in the manufacturing line are primarily composed of the ingredients and mixing process, the sintering operation process, and the treatment of the sintered ore [39, 40].2.2 Important parameters and characteristics of sintering process. As shown in Fig. 2, all variables affecting

More

Design And Fabrication Of Iron Ore Sintering Machine

2015年6月24日 1. 1 DESIGN FABRICATION OF IRON ORE SINTERING MACHINE A Project Report Submitted by ALBIN KURIACHAN CHERIAN (090250121028) SIDDHARTH RATHOD (100253121009) In fulfillment for the

More

Iron ore sintering. Part 3: Automatic and control

Iron ore sintering. Part 3: Automatic and control systems. ... Wuhan Iron and Steel Company (WISCO) in China, in collaboration with Voest-Alpine Industrieanlagenbau (VAI) ... The fundamental objective of the emission

More

China Steel: Production Capacity: Iron Ore Sintering

China Steel: Production Capacity: Iron Ore Sintering data was reported at 1,073,930.000 Ton th in Dec 2013. This records an increase from the previous number of 985,820.000 Ton th for Dec 2012. China Steel: Production Capacity: Iron Ore Sintering data is updated yearly, averaging 592,230.000 Ton th (Median) from Dec 2001 to 2013, with 13 observations.

More

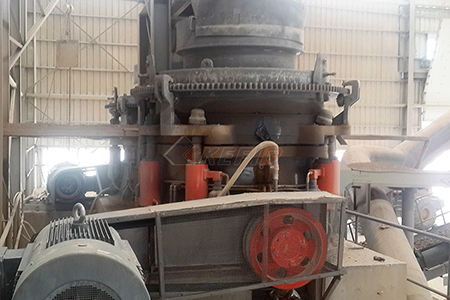

Iron Ore Sintering Machine - Made-in-China

China Iron Ore Sintering Machine wholesale - Select 2024 high quality Iron Ore Sintering Machine products in best price from certified Chinese Machine For Plastic manufacturers, Machine For Metal suppliers, wholesalers and factory on Made-in-China

More

Recent Advances and Research Status in Energy Conservation of Iron Ore

2017年9月19日 For the ferrous burden of blast furnaces in China, sinter generally accounts for more than 70% and the sintering process accounts for approximately 6–10% of the total energy consumption of the iron and steel enterprise. Therefore, saving energy during the sintering process is important to reduce the energy consumption in the iron and steel industry. This

More

Iron ore sintering. Part 3: Automatic and control systems

2015年11月6日 Iron ore sintering. Part 3: ... a pollution control system must monitor the particle matter and gases generated and emitted into the atmosphere by the ... WISCO Wuhan Iron and Steel Com pany, (China)

More

Emission Control of Toluene in Iron Ore Sintering Using Catalytic ...

2023年2月16日 Iron ore sintering flue gas containing large amounts of volatile organic compounds (VOCs) can form secondary photochemical smog and organic aerosols, thus posing a serious threat to human health and the ecological environment. Catalytic combustion technology has been considered as one of the most prospective strategies for VOC elimination. This

More

Calcium Ferrit Generation During Iron Ore Sintering —

2015年5月6日 Iron ore sintering is a heat treatment process for agglomerating fine particles into larger lumps, ... Take a sintering plant in china as an example. ... P.Bert, M.Arnulf. Phase Equilibria in the System CaO-Iron Oxide in Air and at 1 Atm. O 2 Pressure. Journal of The American Ceramic Society, 1958, 41 ...

More

manganese ore sintering plant technology in india

Iron ore crushing is actually the preparation process that are needed for decreasing the size of iron ores during all iron ore processing technology .... Limestone Quarry Plant In the limestone crushing plant, there are hammer crusher and impact crusher for big abridgement ratio ...For the limestone grinding equipment, Ball mill,raymond mill is common.

More

Emission Control of Toluene in Iron Ore Sintering

2023年2月16日 Iron ore sintering flue gas containing large amounts of volatile organic compounds (VOCs) can form secondary photochemical smog and organic aerosols, thus posing a serious threat to human health and the

More

Recent advances in iron ore sintering Semantic Scholar

2016年7月2日 Sintering is the most economic and widely used agglomeration process to prepare iron ore fines for blast furnace use. Owing to the depleting reserves of traditional high grade iron ore, there have been considerable changes in iron ore resources available throughout the world, especially in steel mills in East Asia. Corresponding to the changes in the availability

More

Review Iron Ore Granulation for Sinter Production: Developments ...

most research on iron ore granulation has been focused on the sintering process for decades.11–13) After the 1950s, sys-tematic research on the sintering mechanism was carried out worldwide,14–16) and iron ore sintering was divided into two Iron Ore Granulation for Sinter Production: Developments, Progress, and Challenges

More

Thermodynamic Analysis of Iron Ore Sintering Process Based on

Iron Ore The composition of the iron ore used in this paper is listed in Table 2. Table 2. Composition of iron ore (mass, %). Iron Ore Fe2O3 Fe2O3H2O FeO SiO2 CaO Al2O3 MgO S Composition 49.79 37.21 5.73 3.86 0.39 2.62 0.17 0.11 2.1.3. Other Materials In addition to solid fuel and iron ore, other materials in the sinter process include flux ...

More

Research Progress of Intelligent Ore Blending Model - MDPI

2023年2月13日 The iron and steel industry has made an important contribution to China’s economic development, and sinter accounts for 70–80% of the blast furnace feed charge. However, the average grade of domestic iron ore is low, and imported iron ore is easily affected by transportation and price. The intelligent ore blending model with an intelligent algorithm as

More

Iron ore granulation for sinter production: Developments,

produced iron-bearing charge, most research on iron ore granulation has been focused on the sintering process for decades 11-13). After the 1950s, systematic research on the sintering mechanism was carried out worldwide 14-16), and iron ore sintering was divided into two systems: iron ore granulation and extraction-ignition sintering.

More

Thermodynamic Analysis of Iron Ore Sintering Process Based on

2020年11月16日 The sinter process of iron ore with biomass carbon instead of coke breeze as fuel was investigated via thermodynamic analysis in this paper through a comparison of sinter composition indexes, metallurgical properties, and pollutant emissions. Straw charcoal was used in this paper, and its replacement does not adversely affect the composition index of iron ore,

More

A new disposal method for white mud: Replacing limestone in iron ore

2023年12月15日 Sinter is a product of the iron ore sintering process, which is a widely used pretreatment for ironmaking raw materials (Zhou et al., 2017a). More than 70% of the pig iron smelted in blast furnaces in China comes from sinter (Zhou et al., 2018a).

More

Reductants in iron ore sintering: A critical review - ScienceDirect

2023年1月15日 Moreover, the conventional iron making unit, i.e. blast furnace requires the raw material in the form of iron oxide with a size range of 10–120 mm. Sintering is the oldest agglomerate thermal process using iron ore mineral fines of 0.5–8 mm, along with the reductant, fluxes, and other byproducts of the iron and steel industry operated around a temperature of

More

Iron ore sintering. Part 3: Automatic and control systems

2015年11月6日 Iron ore sintering. Part 3: ... a pollution control system must monitor the particle matter and gases generated and emitted into the atmosphere by the ... WISCO Wuhan Iron and Steel Com pany, (China)

Morefabricants de matériel de traitement des minéraux de cauxite

- fabrication française concasseur de pierre

- sociétés minières au ghana qui exploitent des mines pour les particuliers

- Les Fabricants De Broyeur A Còne En Malaisie

- poudre de tungstène disponible

- pour le broyage du ciment Raymond moulin de

- fournisseur poudre meuleuse amende en inde

- broyeur de pierre ton en indonésie

- Les fabricants de concassage d'agrégats et l'usine de traitement de 300 tons

- stonequipement de sstoneparation des mines d'or

- Carrière de granulats en Inde

- amphibolite est utilisé dans

- faire une carrière

- lignite concasseur broyeur

- mines de boulets en afrique du sud

- concasseur mobile de roche de shanghai