wet screening plant

Principles of Screening and Sizing - 911 Metallurgist

How Application Factors Affect Capacity and Accuracy. Application / modifying factors: Half size in feed – Higher % of half size increases capacity. Oversize in feed – Lower % of oversize

More

Crushing and Screening Handbook - AusIMM

mounted crushing and screening plants for pri-mary, secondary and tertiary stages according to your application. Moving along the quarry face the track-mounted units replace dump truck

More

Mechanical screening - Wikipedia

Mechanical screening, often just called screening, is the practice of taking granulated or crushed ore material and separating it into multiple grades by particle size. This practice occurs in a

More

Taken from Recent Advances in Mineral Processing Plant Design;

INTRODUCTION. Screening is the process of separating particles by size and fine screening typically refers to separations in the range of 10 mm (3/8 inch) to 38 microns (400 mesh). Fine

More

FINE SCREENING - Derrick Corporation

The highest open area urethane screen available – from 0.25 inch (6.2 mm) to 325 mesh (45 microns)*. The development of fine mesh, high open area, urethane screen surfaces is

More

Screening Plants — Types, Working Principle

2018年3月1日 For example — In a mining process, a screening plant is a type of machine used to extract ores from the ground using water and sedimentation processing.

More

Horizontal Screens

Wet screening is used for screening moist, clayey and muddy materials, and increases screening efficiency. Horizontal screens are widely used in aggregate, concrete and asphalt recycling plants, and for a wide range of applications in

More

Crushing and Screening Handbook - AusIMM

Lokotrack primary mobile crushing plant to fur-ther processing stages. They are able to follow the primary unit as it moves along the quarry face, replacing costly dump truck haulage. Plant automation systems – monitor and control all crushing, screening, storing and con-veying with real-time accuracy. Maintain maxi-

More

Screening Equipment 101 Kemper Equipment

Although most screening equipment functions the same, each industry has its own use for these machines. Recycling plants might use screening equipment to separate trash and compost from recyclable materials like glass and plastic.

More

Screening 101 - 911Metallurgist

2016年6月10日 Screening is the passing of material through definite and uniform apertures is the only true and accurate means of grading to a required particle size. Air separation and hydraulic classification depend upon gravity and particle shape, and result in the segregation and retention of material of higher specific gravity and lower surface area irrespective of size.

More

Mobile, Portable and Modular Screening Plants Equipment

Frontline Machinery is proud to carry the best Screening Equipment in Canada. Frontline is proud to carry an extensive line-up of mobile, portable and modular screening plants and scalping equipment. All designed to fit various applications, these machines provide the best performance to screen aggregate, construction demolition waste, biomass, municipal waste,

More

Crushing and Screening Plant Design - Fraser-Lever

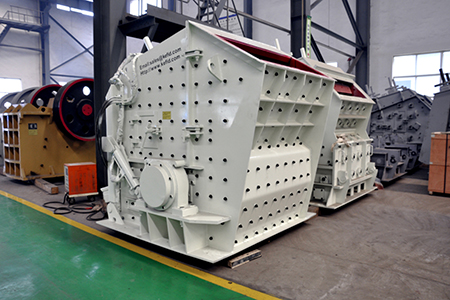

Fraser Lever was involved in the upgrade and expansion of a US$4.5 million project in Indonesia. The existing crushing plant required expanding to 7Mtpa of product to produce a range of products from 300mm rock down to fine washed sands utilizing jaw and cone crushers, impactors, vibrating grizzlies, wet and dry screening, trommels and cyclones.

More

Screening Plants for Narrow Spaces (Australian Guide)

2024年5月2日 Lilly pillies are popular screening plants around the country and this variety has been bred by Ozbreed as a solution for gardeners with narrow spaces. ... 9 Plants That Like Wet Feet (Australian Guide) Fast Growing Climbing Plants for Fences (Australian Guide) My Favourite Flowering Plants for Pots ...

More

The Best Plants For Wet Soils - Australian Plants Online

Exotic Plants To Suit Wet Soil. Of course Australia isn't the only country with extremes of weather, and excess rainfall to deal with. There's many non-native plants that really thrive in moister conditions, like these flowering beauties. Above: bachelor's buttons - Kerria, oyster plant - Acanthus, may bush - Spiraea, mophead hydrangea

More

Mobile Screening Plant Hire - Saundex Contracting

We provide the mining and civil construction industries with our reliable crushers available for wet and dry hire across Western Australia. Screening, the second step in the material handling process, uses screening equipment, our Terex Finlay 883 Reclaimer Screen, to separate raw material from the jaw crusher into even finer grades. Our mobile screening plant is frequently

More

Screening Plants — Types, Working Principle Applications

2018年3月1日 Screening is the process by which granulated ore material gets separated into different grades of particle size. In other words, it’s a mechanical process that stratifies (divides) particles

More

Taken from Recent Advances in Mineral Processing Plant Design;

Screening is the process of separating particles by size and fine screening typically refers to separations in the range of 10 mm (3/8 inch) to 38 microns (400 mesh). Fine screening, wet or dry, is normally accomplished with high frequency, low amplitude, vibrating screening machines with either elliptical or straight-line motion. Various types of

More

wet screening plant - Spanish translation – Linguee

Many translated example sentences containing "wet screening plant" – Spanish-English dictionary and search engine for Spanish translations.

More

Vibratory Screening and Dewatering - Tinsley

The Derrick Stack Sizer is a high capacity, multiple deck, wet screening machine capable of high capacity wet screening in a small footprint. A single slurry input is equally divided in a Derrick flow divider prior to the Stack Sizer. Each

More

Twin Screw Plant 6x20

Screening Plants ; Misc. Impact Crushing Plants. Cone Crushing Plants. Jaw Crushing Plants. RDO Load Out Bin. 5220 Rip Rap Plant. Belt Feeder 15 Yd. 516 Wash Plant. ... Screen Wet Kit. GPM @ 80psi (estimated) - 2000; Spray Nozzles - 1/4" Sandscrews - 36" x2 5' Drive Type - Electric; Horsepower - 20; Screw Shaft Diameter - 10;

More

Portable 5163 Wet Screen - Rock Systems

Portable 5' x 16' triple deck incline wet screen. RD Olson portable wash plant with 5’ wide x 16’ long triple deck incline wet screen, 20 h.p. electric motor drive, 100 mm bearings with oil bath lubrication, manifold for water supply with 5 spray bar wash system per deck, rubber hoses and ball valves, slurry feed box, individual oversize discharge chutes, collecting hopper mounted

More

Trailer-Mounted Portable Wash Plant For Sale - RR Equipment

Can be customized to meet your needs! Choose a screen washer. We will do the rest – OR – Choose from one of our more popular plants below. PORTABLE SCREENKING® SKWP5163 WASH PLANT. Entire plant will be mounted on a heavy duty single axle dual wheel chassis complete with air brakes, mud flaps, and fifth wheel pin. Features:

More

Crushing and Screening Plant Design - Fraser-Lever

Fraser Lever was involved in the upgrade and expansion of a US$4.5 million project in Indonesia. The existing crushing plant required expanding to 7Mtpa of product to produce a range of products from 300mm rock down to fine washed sands utilizing jaw and cone crushers, impactors, vibrating grizzlies, wet and dry screening, trommels and cyclones.

More

Wet Mobile Crushing And Screening Plants

To sum up, wet mobile crushing and screening plants offer a host of benefits that can revolutionize your material processing operation. From handling wet materials and controlling dust to enhancing mobility and efficiency, these plants are a valuable asset for any mining or construction project.

More

Iron Ore Processing Plant - CFlo

Accurate screening through our wet systems allows you to unlock the true value of medium grade iron ores, reducing your reliance on purchasing only high grade ore and ultimately reducing your raw material costs. We have developed advanced systems to ensure that the feed to your plant is accurately calibrated and offer the following benefits:

More

S:MAX™ Static Sludge Screening System - Sludge Management

Blockages within existing sludge screening plants are the single biggest cause of increased operational costs and long periods of plant downtime. A unique back wash system on the S:MAX ensures that the screens do not block with material offering utilities and contractors a significant reduction in the cost of operation and maintenance as well as an increase in plant uptime.

Moreexploitation minière historique

- carrire Est Un Concasseur Tertiaire

- mini jet de sable

- rendement de concassage

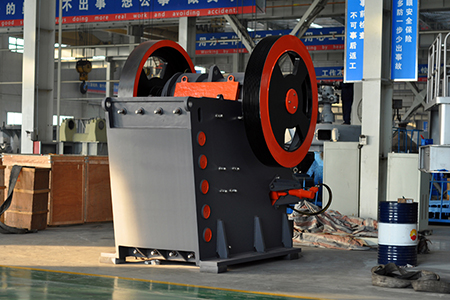

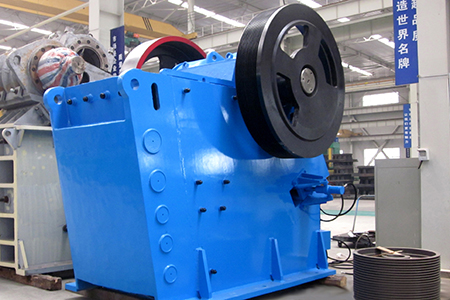

- machine de concasseur à mâchoires série pe machine de concasseur de minerai d or p

- convoyeur à chaîne en treillis métallique

- Haute qualité mini mâchoire concasseur de pierre prix concasseur de sable à vendre

- tuyaux sans soudure concasseur

- articles de l histoire de concassage de pierre dans pakistan

- Miller fabricant de la machine inde moulin a Granding

- différence concasseur youtube

- afrique du sud machines concasseur de pierre en Inde

- Usine de concasseur de pierre dans le Gujarat en Inde

- de cacao en prix de meuleuse commerciale

- broyeur à boulets utilisés pour la vente de l'exploitation minière

- faire progresser la technologie de la sbm