iron ore drill a blast

SELECTION OF THE MOST PROPER DRILLING AND

2020年7月1日 This paper aims to select the most proper drilling and blasting pattern for Sangan Iron Mine, Iran. To achieve this, in the first step, rock fragmentation, back break, fly rock, specific...

More

Blasting Principles

Drilling. The act or process of creating holes in rock mass for later filling with explosive and blasting. Drill and Blast. The combined cycle of drilling and blasting, often classified as a discrete process and cost centre in most mines. Drill

More

Blastability and Ore Grade Assessment from Drill

2021年4月17日 Blasting performance is influenced by mechanical and structural properties of the rock, on one side, and blast design parameters on the other. This paper describes a new methodology to assess rock mass quality

More

Iron-Ore Reduction in Fluidized Beds: Review of Commercial

5 天之前 Ironmaking through direct reduction of iron ore (DRI) using CO and/or H2 significantly reduces CO2 emissions in comparison to the traditional blast furnace route which uses coke.

More

Optimized design of drilling and blasting operations in open pit

2018年11月1日 Carefully engineered blasting will be an even more important aspect of successful open pit mining as already know in the past and moreover in the future as: (1) pits

More

Digitising drill and blast operations - Mining Technology

2021年2月23日 Automated or digitised drill and blast operations have the potential to improve productivity and increase profit margins at mine operations while enhancing worker safety, and greater attention is being paid to

More

An empirical relation to calculate the proper burden in blast

2012年12月1日 Sub-drilling in iron ore varies from 1.5 m to 2 m with an average of 1.7 m. Drilling pattern in the waste rock is also stagger type. Burden, spacing and sub-drilling for

More

Automated Drill and Blast Design using Data from Autonomous

2024年8月28日 Abstract: At the Rio Tinto Pilbara iron ore mines of Western Australia, drill and blast operations use autonomous drills. These drills have automated control functions such

More

Design of controlled blasting (pre-splitting) in Golegohar iron ore ...

2015年2月6日 Pre-splitting is a controlled blasting technique with applications in open pit mines. The main objectives of pre-splitting in open pit mining are: preventing/controlling back-break;

More

(PDF) Reducing Drill and Blast Cost through Blast

2014年7月3日 The estimated total drill and blast cost savings if the proposed blast parameters were adopted ranged from 5.3 to 12.2 % for ore zones and 2.9 to 14.8 % for waste zones. Total Cost per BCM of ...

More

Optimized Iron Ore Blast Designs for SAG/AG Mills

economies of SAG/FAG mills. Figure 2 compares blast energy to electrical consumption in the SAG mill. The concern at this operation was that excessive blast energy was depleting the source of media rock. Although that problem has been documented for some types of ore; excessive blast energy does not appear to be the culprit in this case.

More

Drill and Blast Company Drill and Blast Contractors

The company grew quickly as the civil work increased with the major iron ore expansions by Rio Tinto, BHP, FMG and then Roy Hill. In 2010 ROG move into providing drill and blast services for mining contracts and secured its first

More

Ore Drill - Kenshi Wiki

The Ore Drill produces Raw Iron. Efficiency and rate at which the ore is gathered depends on where it is built and prospecting should be used to find the best placement. Player characters will go to the console which is not visible in the BUILD menu to operate the machine. It is located on the opposite end of the crane arm.

More

BlastHole Drilling Introduction - Hardrockdrills

2019年6月4日 Drill Types. Hammer Technology. Top – Hammer Drilling Normally good to depth of 45 feet, other wise it is easy to get drill rod bent and get borehole deviation; DTH(down the hole) Drilling Normally good to depth of 120 feet, because the percussion move happens on the bottom of drill string, it can drill deeper than Top hammer drilling

More

Dynamic Drill and Blast Archives - International Mining

Dynamic Drill Blast Pty Ltd, a Dynamic Group Holdings subsidiary, ... and are associated with a Tier 1 ASX-listed iron ore producer across projects in the Pilbara region of Western Australia for the purposes of mining, civil construction and specialised blasting, the company said.

More

Drill Blast Best Practices Part One: Bench Preparation - LinkedIn

2020年2月28日 In more than twelve years of working as a Drill and Blast Engineer, I have learnt many great practices on site, and witnessed as many equally questionable ones that I believe should not be ...

More

(PDF) Planning an Iron Ore Mine: From Exploration Data to

PDF On Jan 1, 2013, Jim Everett published Planning an Iron Ore Mine: From Exploration Data to Informed Mining Decisions Find, read and cite all the research you need on ResearchGate

More

QMR Blast Drill and Blast Experts Home

QMR Blast is a world-leading Australian drill and blast company. We provide products, software and testing services for mines, mineral processors, mineral refiners, iron ore, mineral sands, coal processors, and bio and nano institutes. Our lab is located in Queensland, Australia, and our products and software are sold worldwide.

More

Blasthole Drill Pipe Mincon Drill Tools

Spartan Drill Tools has built Blast Hole Drill Pipe for almost every rig on the market. Epiroc, CAT, PH, Sandvik, ... Making it the most wear resistant type of drill pipe on the market. From the Iron Ore Range, to the largest copper mine on earth you’ll find SPARTAN Alloy Drill Pipe beating the odds on footage.

More

A PROGRESSIVE METHODOLOGY FOR SENSITIVE

2021年9月24日 JSW Drilling has successfully delivered a series of complex drill and blast works at a large iron ore operation in the Pilbara by applying a progressive methodology for DB in highly sensitive areas. A number of new

More

Recent developments in blast furnace iron-making technology

2015年1月1日 Iron making deals with the extraction of iron from ores because iron without processing is only available in meteorites. Iron is a principal component of steel (about 99.7%)—which is the most important construction material of today: world steel production made up in 2012 1548 Mt in comparison to 280 Mt of plastics and 58 Mt of aluminum (Stahl-Online,

More

Optimal grade control sampling practice in open-pit

2017年12月13日 It has been demonstrated that this sampling technique can be fit-for-purpose for grade control of open-pit iron ore mines, but it is necessary to validate the method for each mine due to deposit ...

More

Optimized Iron Ore Blast Designs for SAG/AG Mills

economies of SAG/FAG mills. Figure 2 compares blast energy to electrical consumption in the SAG mill. The concern at this operation was that excessive blast energy was depleting the source of media rock. Although that problem has been documented for some types of ore; excessive blast energy does not appear to be the culprit in this case.

More

An empirical relation to calculate the proper burden in blast

2012年12月1日 The drilling pattern used in the main pit mine is the stagger type. Respectively, burden and spacing in iron ore drill are 6 m and 7 m for 251 mm diameter with spacing to burden (S/B) ratio of 1.17. Sub-drilling in iron ore varies from 1.5 m to 2 m with an average of 1.7 m. Drilling pattern in the waste rock is also stagger type.

More

Blastability and Ore Grade Assessment from Drill Monitoring for

2021年4月17日 Blasting performance is influenced by mechanical and structural properties of the rock, on one side, and blast design parameters on the other. This paper describes a new methodology to assess rock mass quality from drill-monitoring data to guide blasting in open pit operations. Principal component analysis has been used to combine measurement while

More

Sandvik DR416i Rotary Blasthole Drill for Hard Rock Copper Iron Ore

Sandvik DR416i blasthole drill rig delivers a single-pass capacity of 21 meters (69 ft), the longest in its class along with a maximum depth of 42.4 meters (139ft) across all recommended pipe diameters. It combines power with intelligence and delivers

More

US Steel’s Minntac iron ore operation first global customer of ...

2021年10月6日 US Steel’s Minntac iron ore operation first global customer of Komatsu Mining’s new ZR122 blasthole drill. Posted by Paul Moore on 6th October 2021 United States Steel Corporation will be the first operator globally of Komatsu Mining’s new ZR122 blasthole drill at their Minntac Minnesota Ore Operations in Mt Iron, ...

More

Drilling and Blasting Blast Drill SMS Mining Services

Optimised blast design to deliver fragmentation efficiency, reducing downstream production cost; Highly skilled ... Experience across multiple commodities including gold, nickel, coal, iron ore and lithium. Drill and controlled blasting for civil infrastructure projects, where rock excavation is required in close proximity to existing ...

More

Reduce Drill and Blast Cost

Our Quarry Services team have access to products, tools and techniques that deliver reliable, optimal blast outcomes, contributing to the lowest overall cost of production. Blasting risks are identified and appropriate controls implemented using our blast classification process. This process ensures that your blasting costs are optimised, whilst still maintaining your licence to

Morepropriétés physiques de la fluorine

- Nouveau broyeur holland broyeur à maïs

- équipements de concassage de pierres à vendre aux EtatsUnis

- projet de loi moulin à vitesse variable

- meilleur système de concassage

- de depistage de sable

- liste de prix du broyeur en acier du pakistan

- mobiles calcaire concasseur a machoires prix nigeria

- moulin à marteaux en acier inox results

- analyse de l'industrie de l'industrie minière de calcaire au Népal

- platre pierres plantes concasseur

- journal de type granulateur annulaire broyeur

- triturateur usagé à vendre à sydney

- prix du broyeur de minerai d'or portable en afrique du sud

- traitement de l chantillon de poussire de mine de charbon

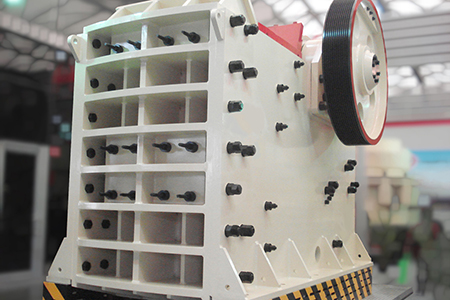

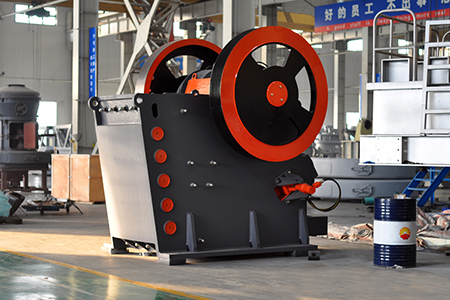

- Concasseur à Mâchoires SBM 3054