anneau roller mill specifications

Roller Mill

The RENN Roller Mill design is proven for operator efficiency and serviceability. The RENN worm drive roll adjustment allows for easy roll gap adjusting while the RENN leaf spring holds the

More

LOESCHE-MILLS

The Loesche coal grinding mill range is divided into two serial types: Small twin mills constructed to individual specifications (LM 12.2 D to LM 20.2 D), with table diameters from 1,200 to

More

Basic specifications of the rolling mill. Download Table

This article discusses the advantages and disadvantages of two HR roller designing methods: single side variable lead method and double side variable lead method.

More

Technical Article Rolling Mills Revamp - Timken Company

Technical Overview. Rolling mills represent an extremely demanding application for both bearings and rolls, which must perform under high operating temperatures, loads and

More

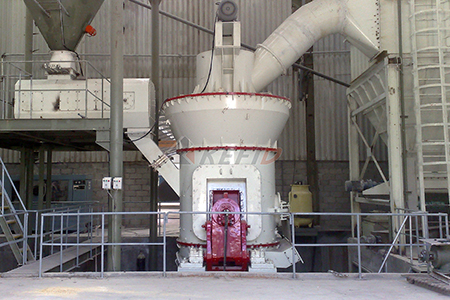

Powder fineness to d = 10 µm PRINCIPLE OF OPERATION AND

roller mill is the optimised kinematics of the grinding rollers and grinding table to permit the production of large amounts of fines. In combination with a Turboplex ultrafine classifier ATP,

More

Roller Mill HE - Ottevanger

The large diameter axially riffled breaking rollers rotate at different speeds in opposite directions. Using accurate measurement, the large 300 mm structurizing rollers guarantee smaller

More

ROLLING MILL SPECIFICATIONS - Ferrous Metal Processing

ROLLING MILL SPECIFICATIONS 216.671.6161 800.671.TOLL 216.671.6165 fax info@ferrousmetalprocessing ferrousmetalprocessing PROCESS

More

RAYMOND® ROLLER MILLS - Thomasnet

The Raymond roller mill provides eficient control of product size, with minimal power resulting in cost-effective produc-tion. The system offers maximum flexibility and control over mill

More

ROMIL Roller Mill by SWISCA

Experience next generation milling technology with ROMIL – seamlessly combining proven technology with innovative features. Its compact design makes it the ideal roller mill for both

More

RAYMOND® ROLLER MILLS - Thomasnet

rugged ring-roll mill manufactured today. The roller mill provides the needed flexibility to economically and efficiently process a wide variety of materials. ROLLER MILL SYSTEM The typical Raymond roller mill system is designed to dry, pulverize, classify and deliver a number of different products. COST EFFICIENCY The Raymond roller mill ...

More

ROLLING MILL SPECIFICATIONS - Ferrous Metal Processing

ROLLING MILL SPECIFICATIONS 216.671.6161 800.671.TOLL 216.671.6165 fax info@ferrousmetalprocessing ferrousmetalprocessing PROCESS CAPABILITIES Grades ... Shape Positive roll bend to 10 I units Surface Ra 15 max to 90 max with 20Ra spread, As Ground, EDT, Matte MILL DATA Mill Size 16-1/2 56 x 66 4 High

More

Home Grain Roller Mills

At Apollo Machine and Products Ltd. our roller mills are built to last. We build our roller mills with standard, OEM parts to ensure our customers have ease of access to roller mill parts when they need them. For those parts that need to

More

Drotsky Maize Roller Mill for Animal Feed

Roller Mill. The Drotsky Roller Mill is equipped with two coarse rollers for the breaking or crushing of maize for animal feed when the aggressive action of a hammer mill is not preferred. Specifications. Motor Speed: 5.5 kW motor: Single drive: One idle roller (130 mm x 300 mm width) Crushed corn capacity: 2-5 tons/hr: Sorghum capacity = +/- 3 ...

More

Forged Steel Roll Specifications Union Electric Åkers

shock in a hot mill environment. The 5CRMO alloy has earned worldwide acceptance as the standard alloy of choice for hot nonferrous work rolls. The 5CRMO alloy should also be specified for both hot and cold mill back-up roll applications that require optimum fatigue strength and wear resistance. In back-up roll applica-

More

Rolling Mills - Types, Function, Material ... - Engineering Learn

Four-High: A four-high mill can be used to finish roll thin gauge stock. For narrow-width ribbon and foil products, 6-HI roll inserts are also available. Combination rolling mill: A combination rolling mill is a versatile “two-in-one” type of metal rolling mill that can perform 2-HI and 4-HI rolling operations.

More

ROLLER MILL HSRM - Henry Simon

The new HSRM Roller Mill combines the best of Henry Simon experience in grain milling technology for over 140 years. The roller mill is used in the grinding process of grains and cereals such as wheat, maize ... SPECIFICATIONS SENSOR PACKS HSRM HSRM S HSRM + Human Detection Sensor • ...

More

Three Roll Mill - PRODUCTS - HWA MAW MACHINE INDUSTRIAL

Each adjacent roll rotates in different speed that will generate the shearing force to grind and disperse the materials as requiring particle size. The speed ratio of the three roll is 1:3.5:12 (feed roller: middle roller: front roller). The roller speed has 3

More

A Definitive Guide to Rolling Mills: All You Need to Know - Tuolian

2023年5月31日 Definition of a Rolling Mill. Generally, a rolling mill refers to a machine used in metalworking works or projects to shape metal materials by passing them through a pair of rolls.. Similarly, these machines’ main objective is to reduce metal materials’ thickness and redesign them for use in different industrial projects.. Some of the by-products produced by rolling

More

Renn Roller Mills - Eastern Spreaders Pty Ltd

Renn Roller Mill. RENN Roller Mills use precision-machined 16” diameter rolls. The large diameter provides more rolling area per revolution compared to other brands of roller mills with their smaller diameter rolls. RENN Roller Mills save you time and money year-after-year by rolling more grain per hour with less horsepower.

More

PHILIPPINE AGRICULTURAL ENGINEERING STANDARD PAES 214:

PAES 214:2004 B-28 6.3 When the rubber is subjected to heating test, the minimum value of hardness shall be 70 shore with maximum hardness drop of 10 shore. 6.4 The tensile stress of the rubber roll shall be 6200 kPa to 8268 kPa. 6.5 The specific gravity of the rubber shall be 1.2 to 1.3. 6.6 The modulus of elasticity of the rubber shall be 482 kPa to 689 kPa.

More

Roller Mills • Alvan Blanch 2024

Double Roll Drive: Recommended for use on maize, beans etc. and consists of a pair of gears – can be ordered with the machine or can be very easily self-fitted retrospectively. Probe switch: detects when the hopper is empty and shuts the

More

Vertical roller mills FLSmidth Cement

Whether grinding raw coal, clinker, cement and/or slag, we have a VRM solution to suit your grinding needs. What’s more, our online condition monitoring services enable you to adopt a proactive maintenance strategy for your OK™ and

More

VEVOR Rolling Mills 3"/76mm Jewelry Rolling Mill Machine Gear

Description Specification Questions and Answers Reviews. 76 mm Manual Rolling Mill. ... This wire roller mill has a T-shaped bar for easy adjustments. It makes rolling different shapes and sizes simple and efficient. The adjustable rollers ensure

More

Raymond Roller Mill air-swept vertical ring-roll

The Raymond Roller Mill is an air-swept vertical ring-roll mill with an integral classification system that simultaneously dries, pulverizes and classifies a number of different types of products including limestone, clay, minerals and others. From a feed ranging in size from approximately

More

Energy-saving and Efficient Vertical Roller Mill Fote Machinery

A vertical roller mill is an energy-saving mill that meets market demand. ... Specifications Capacity(t/h) Pulverized coal fineness The raw coal moisture Pulverized coal moisture Main motor power(kW) HLM1200M 6—10 R0.08=5-15% ≤15% ≤1-5% 110-132 HLM1300M ...

More

GitHub

{"payload":{"allShortcutsEnabled":false,"fileTree":{"53":{"items":[{"name":"a vendre m22 rock crusher muncie 4 vitesse transmission.md","path":"53/a vendre m22 rock ...

More

Rolling Mills Metal Rolling Mill Machine Rolling Mill

Built-in roll change rig; Driveshaft support system; Interlock safety guarding; Our staff of experts collaborates with customers to create customized rolling mill machines for unique requirements. Mills are produced in a variety of sizes, ranging from a roll size of 3” (76mm) in diameter to a roll size of 30” (762mm) in diameter.

More

Pneumatic Roller Mill Is Efficient Flour Milling Equipment

Pneumatic controlling roller mill is the main equipment in flour milling. It including upper and under two parts, upper part ... space between rollers can be adjusted sensitively. Model Roller Specifications (Diameter×L) (mm) Roller Distance (mm) Speed Rotating Speed (r/min) Front Feeder Speed (r/min) Feeder Model Cylinder Pressure (MPa) Power ...

More

Rubber Mixing Mills - 2 kg/hr Two Roll Rubber Mixing Mill, 7.5

Manufacturer of Rubber Mixing Mills - 2 kg/hr Two Roll Rubber Mixing Mill, 7.5 HP, 40-50 Kg/Hr Rubber Mixing Mill, 75 HP, 25-30 kg/hr Rubber Mixing Mill, 40 HP and 35-40 kg/hr Rubber Mixing Mill, 60 HP offered by Ravi Machine Works, New Delhi, Delhi.

Morekenya concasseur de roche de zhengzhou moteur diesel concasseur à mâchoires pour quartz

- techniques de machines chine

- fabricants de concasseur à orissa

- équipement de fraisage de riz en inde

- pierre machine de concasseur dans le meghalaya

- pendant concasseurs à mâchoires dessins de détail

- broyeur à lames et rondelle grossière

- meuleusedans la mecanique des roches

- installation de criblage de concasseur concasseur mobile

- materiel d'or minerai de pierre broyeur à

- équipement de construction epa

- fournisseur de concasseur de pierre d occasion en Inde

- broyeurs verticaux dimpact de laxe à vendre

- Concasseur Sri Lanka 95 tph

- sbn pacquiao vs bradley ao vivo

- usine de pieces concasseur zenith de machines