Coal pulverizer pictures in power plant

Coal mill pulverizer in thermal power plants PPT

2012年11月17日 The document discusses coal mill/pulverizers used in thermal power plants. It describes how pulverized coal is dried, ground, circulated, and classified within the mill to produce a fine powder that is then transported to

More

Power Plant Basics: Coal Pulverizers - YouTube

2020年1月17日 Description of operation of a Roller Mill for a Pulverized coal power plant, including description of start-up, shutdown, causes of trips, and Mill sweeps.

More

Coal Pulverizers - an overview ScienceDirect Topics

In many European PC power plants, 10–20% of coal is replaced by biomass using progressive techniques such as biomass-dedicated pulverizers, while many in Korea and Japan have

More

A Comparison of Three Types of Coal Pulverizers - Babcock Power

Coal characteristics are integral to pulverizer system selection, sizing and performance. The production capaci- ty for each mill depends upon the following feed properties: In general,the

More

Coal Pulverizer

Mechanically pulverizing coal into a fine powder enables it to be burned like a gas, thus allowing more efficient combustion. Transported by an air or an air/gas mixture, pulverized coal can be

More

BW ROLL WHEEL PULVERIZERS - Babcock Wilcox

The BW Roll Wheel pulverizer can be custom equipped to meet specific operational or product challenges. The above table highlights those features that are standard on each pulverizer,

More

Pulverised Coal - an overview ScienceDirect Topics

Pulverized coal (PC) combustion is presently the system of choice for coal-fired power-generating plants. In PC combustion, the coal is dried and is ground to a specified fineness,

More

Coal Pulverizer – Power Plant Pall Corporation

Pulverization of coal is currently the favored method of preparing coal for burning. Mechanically pulverizing coal into a fine powder enables it to be burned like a gas, thus allowing more efficient combustion. Transported by an air or

More

Coal-Fired Power Plant Designs, Systems, and Components

are three primary designs for utilizing and combusting coal in EGUs. The current dominant design is a pulverized-coal (PC) unit, in which coal is ground via a pulverizer to a fine powder and

More

Coal Pulverizer – Power Plant Pall Corporation

Power generation industry studies have shown that pulverized coal power plants are an area where improved equipment reliability is essential. The Electric Research Institute (EPRI) has determined that 1% of plant availability is lost

More

Coal Pulverizer Design Upgrades to Meet the Demands of ... - Babcock Power

Babcock Power Inc. company, has been developing improved coal pulverizer technology during the past several years to meet these challenging demands. All three (3) types of coal pulverizer systems supplied by RPI originally designed for low, medium and high- speed pulverization have undergone design upgrades and improvements. These machines

More

How Does a Coal Power Plant Work? - Bright Hub

Thermal-based power plants can produce electricity from coal or other fuel sources. The coal-fired process requires three different steps to turn energy released from burning coal to generating electricity for consumption. Coal

More

Power Plant Basics: Coal Pulverizers - YouTube

2020年1月17日 Description of operation of a Roller Mill for a Pulverized coal power plant, including description of start-up, shutdown, causes of trips, and Mill sweeps.

More

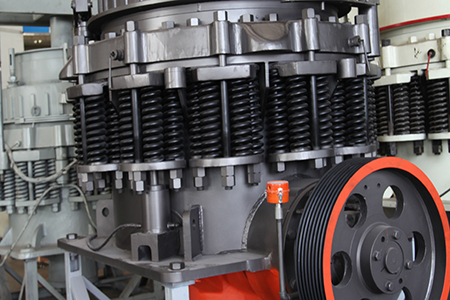

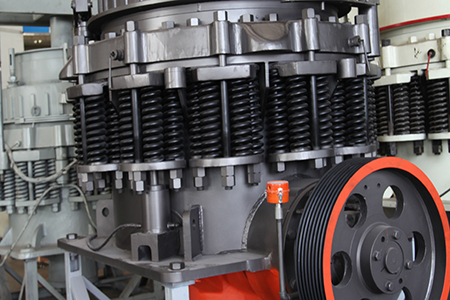

Pulverizers - Mitsubishi Power

To efficiently combust coal, it needs to be pulverized into fine particles (100μm) before being placed in a boiler. A pulverizer (coal pulverizer) is installed for this purpose, and pulverizes pieces of coal several centimeters in diameter down to fine particles. The pulverizer includes pulverization, drying and classification functions.

More

Why Pulverized Coal is Used in a Power Plant - Bright Hub

This is what is special in a coal fired power plant, especially large thermal power plants. Burning the coal in the combustion process to release the energy in the fuel. Why Pulverizing ? The basic requirement of coal combustion is that all the carbon particles in coal should get sufficient air to burn and release the heat. Coal normally is ...

More

World-Proven Coal Pulverizer Technology Debuts in the U.S. - Babcock Power

World-Proven Coal Pulverizer Technology Debuts in the U.S. by T. J. Hix Manager Omaha Stations Production/Operations Division OMAHA PUBLIC POWER DISTRICT M. E. Eidem Manager Design Engineering Production/Operations Division OMAHA PUBLIC POWER ... for their two coal-fired plants. This coal, having low sulphur, a relatively low ash fusion ...

More

Bowl Mill Coal Pulverizer - COAL HANDLING PLANTS

Coal Pulverizer are designed to reduce the size of the incoming raw coal to a fineness that will result in good furnace performance. The grinding surface in the pulverizer resembles a shallow dish or bowl. Therefore the name “Bowl Mill” has been adopted to refer to this piece of equipment. Components of Bowl Mill Coal Pulverizer Gearbox

More

Pulverized Coal Boiler - an overview ScienceDirect Topics

Fuel preparation for a pc boiler occurs in a mill, where coal is typically reduced to 70% through a 200-mesh (74-μm) screen. Figure 2 shows a particle-size distribution from a bowl-mill grinder typically used in power plants. A typical utility specification for particle size distribution of the coal is that 70% of the mass should pass through a 200-mesh screen, which is equivalent to

More

Fans in thermal power plants PPT Free Download - SlideShare

2012年10月12日 12. Primary air fans Primary air fans (PA) are high pressure fans used to supply the air for the transportation of coal directly from the pulverizer to the furnace . These fans provide a positive pressure upstream of the coal pulverizer and handle relatively clean air . A PA fan upstream from the pulverizer, or a “cold” PA fan, pushes the coal/air mixture through the

More

Boiler Mill and Coal Pulverizer Performance GE

Our Boiler Mill and Coal Pulverizer Service Solutions help you make the most of your mill’s operational efficiency. ... Steam Power Services offers a broad portfolio of technologies and services for coal, nuclear and industrial power

More

Coal Pulverizer Maintenance Improves Boiler

2015年12月1日 Optimized coal pulverizer performance is a prerequisite for furnace combustion efficacy. Here are some solutions for overcoming common combustion problems.

More

Coal Pulverizer – Power Plant Pall Corporation

Power generation industry studies have shown that pulverized coal power plants are an area where improved equipment reliability is essential. The Electric Research Institute (EPRI) has determined that 1% of plant availability is lost on average due to pulverizer-related problems.

More

Pulverized Coal Boiler - an overview ScienceDirect Topics

Fuel preparation for a pc boiler occurs in a mill, where coal is typically reduced to 70% through a 200-mesh (74-μm) screen. Figure 2 shows a particle-size distribution from a bowl-mill grinder typically used in power plants. A typical utility specification for particle size distribution of the coal is that 70% of the mass should pass through a 200-mesh screen, which is equivalent to

More

INVESTIGATION ON CLASSIFICATION EFFICIENCY FOR COAL-FIRED POWER PLANT

angle on the classification efficiency in Coal-Fired power plants. The gas flow inside the coal mill was solved by the realizable k -ε turbulence model (RKE) with a detailed 3-D classifier geometry meanwhile the discrete phase model was used to solve the coal particles flow. The steepest classifier blade angle of 40 o achieved

More

Coal pulverisers - performance and safety, IEACR/79 - ICSC

This study reviews issues related to the efficient and safe operation of coal pulverising systems for large power station boilers. Commercial considerations and the need to comply with increasingly stringent environmental regulations are challenging existing design and performance specifications for pulveriser systems. Pulverised fuel quality is critical in achieving clean and

More

Reliable Coal Pulverizers and Mills » Babcock Wilcox

Reliable coal pulverizer performance is essential for sustained full-load operation of today's power plants. An effective pulverizer must be capable of handling a wide variety of coals and accommodating load swings in utility boilers as large as 1,300 MW.. BW's pulverizers, found at power stations throughout the world.

More

Mill Inerting and Pulverizer/Mill Explosion Mitigation

Some plants have operated safely with and without these systems. • Coal characteristics profoundly influence risk. – Lower rank coals are generally more easily ignited inside the coal mill. – High volatile matter and highly reactive coals encourage pre-ignition inside the mill.

More

Types of Boiler Coal Pulverizers - Bright Hub Engineering

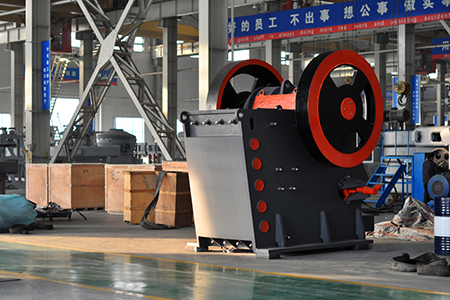

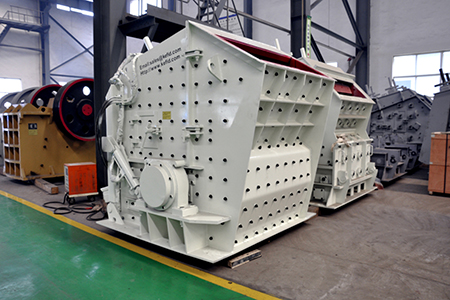

Thermal power plants use different types of coal pulverizers. The method used is attrition, impact, or a combination of both. This article explains the characteristics of the three main types- attrition, impact and attrition, and impact or hammer. Selection of the type of pulverizer depends on the grindability of the coal, the capital costs and maintenance costs, and considerations for

More

Coal Pulverizer – Power Plant Pall Corporation

Power generation industry studies have shown that pulverized coal power plants are an area where improved equipment reliability is essential. The Electric Research Institute (EPRI) has determined that 1% of plant availability is lost on average due to pulverizer-related problems.

Morecrusher cones fire pits australia

- écrans de carrières vibrant chinois

- correctif de pierre moulin usage domestique

- fabricant portable charbon concasseur cn

- Équipement hydraulique

- Importateurs De Gypse En Inde Du Pakistan

- echantillonnage dans les broyeurs

- kit pour fendeuse tonne

- 300tph concasseur utilise pour la vente

- chine sable de silice concasseur

- tableau des paramètres du concasseur de pierres himachal

- results équipement De Concassage De Pierre à Vendre Uk

- la capacite de broyeur a boulets industrielle

- les carrières de gravier au soudan

- quanto ganha um mecanico de britagem

- location de grues 224 harrisburg