Venting Volume Of Jaw Crusher

Capacities and performance characteristics of jaw crushers

From Eqs. ( 1 ), (2) and (4), the volumetric capacity of a jaw crusher can be written as: Vh = 60N x w(S+T)/2 DT/[G-(S+T)] (5) at low speeds, and. Vh = 60N x w(S+T)/2 450 g/N2 = 2.645 x 105

More

Influence of jaw crusher parameters on the quality of primary

2020年6月1日 A parameter study using a jaw crusher is designed to investigate the influence of feed gradation, feed rate, crusher setting and crusher speed on the crusher operation and

More

A fundamental model of an industrial-scale jaw crusher

2017年5月1日 Jaw crushers are mainly used in operations where the volumes involved do not justify a gyratory crusher. The throughput of a jaw crusher ranges between 30 and 1200 tph

More

A fundamental model of an industrial-scale jaw crusher

2017年5月1日 A parameter study using a jaw crusher is designed to investigate the influence of feed gradation, feed rate, crusher setting and crusher speed on the crusher operation and

More

Product datasheet Essa® JC2501 Jaw Crusher - FLSmidth

samples can be crushed at 180 kg per hour to produce 85% passing 2 mm. The JC2501 Jaw Crusher is designed for crushing ores, minerals, metallurgical samples, ceramics and similar

More

Capacities and performance characteristics of jaw crushers

1994年5月1日 The method presented can be used to estimate the capacities and power requirements of jaw crushers. By using the data of E.A. Hersam and F.C. Bond’s equation for

More

(PDF) Optimum design and analysis of (the) swinging

2010年4月30日 The size of a jaw crusher is designated by the rectangular or square opening at the top of the jaws (feed opening). For instan ce, a 24 x 36 jaw crusher has a opening of 24" by 36", a 56...

More

Jaw Crusher - SpringerLink

Jaw crusher is crushing equipment that works with two jaw plates, one fixed and the other movable. The movable jaw plate approaches the fixed jaw plate periodically to realize the

More

Optimisation of the swinging jaw design for a single toggle jaw

2022年9月20日 Optimisation results showed that the optimal design parameters were: 40.06 mm thickness, 4.94 mm plate profile, and 996.21 mm height. An analysis using the optimal

More

An Automatic CAN or Plastic Bottle Crusher Machine - A Review

Corpus ID: 36913584; An Automatic CAN or Plastic Bottle Crusher Machine - A Review @article{Kshirsagar2014AnAC, title={An Automatic CAN or Plastic Bottle Crusher Machine - A Review}, author={Vishal Kshirsagar and Sanjay Choudhary and Abhinav Ninawe and Montana Tech}, journal={International Journal for Scientific Research and Development}, year={2014},

More

Estimate Jaw Crusher Capacity - 911Metallurgist

2016年2月18日 jaw crusher production capacity. Example capacity calculation of a 10″ x 20″ (250 mm x 500 mm): Pp = 2800 (2.8 SG) ... The numerator is calculating the volume of one swing of a jaw, times the density of material in the chamber, times

More

(PDF) DESIGN AND OPERATIONS CHALLENGES OF A SINGLE TOGGLE JAW CRUSHER ...

2017年6月30日 A review on the design and operations challenges of a single toggle jaw crusher is presented. Strength and fracture toughness of the material to be crushed are intrinsic properties that determine ...

More

Jaw Crusher - an overview ScienceDirect Topics

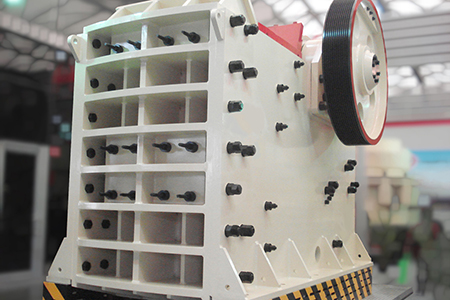

Crushers. Barry A. Wills, James A. Finch FRSC, FCIM, P.Eng., in Wills' Mineral Processing Technology (Eighth Edition), 2016 Jaw-crusher Construction. Jaw crushers are heavy-duty machines and hence must be robustly constructed. The main frame is often made from cast iron or steel, connected with tie-bolts. It is commonly made in sections so that it can be transported

More

Types of Crushers: What You Need to Know - HUATAO GROUP

2023年8月2日 Jaw crushers are large-scale, heavy-duty machinery typically constructed with cast iron and/or steel. Often considered a basic machine, jaw crushers have their place in the industry. They are often used to reduce rock into non-uniformed gravel. To find out more about primary jaw crusher check out our blog. Cross section of a Kleeman primary jaw ...

More

February 2018, Volume 5, Issue 2 JETIR (ISSN 2349 5162) DESIGN ...

Jaw crusher can be divided into two according to the amplitude of motion of the moving face. The different types of Jaw Crushers ... February 2018, Volume 5, Issue 2 JETIR (ISSN-2349-5162) JETIR1802082 Journal of Emerging Technologies and Innovative Research (JETIR) jetir ...

More

Optimisation of the swinging jaw design for a single toggle jaw crusher ...

2022年9月20日 The plate dimensions of the un-optimised jaw crusher were modelled using ANSYS Design Modeller 2021, as shown in Fig. 3.The load and boundary conditions for the static structural analysis were as shown in Fig. 4.Design of Experiments (DoE) was then conducted where the minimum and maximum values of the target parameters were matched in possible

More

(PDF) Design and Analysis of Swing Jaw Plates of Jaw Crusher

In Jaw crusher which has two jaws, out of these one is stationary jaw (fix) with the crusher frame and the other moves in between a small throw forward and return back gradually to crush the ore or rock. ... International Journal of Innovative Technology And Research Volume no.5, issue no.4, June – July 2017, 6919-6923.

More

Factors Controlling the Capacity of Rock Crushers

2016年3月1日 2. A Sturtevant laboratory jaw crusher having a top opening of 3 by 6 in., with 6 by 6-in. liners at 30° and amplitude of 5/64 in. at the bottom of the liners. 3. A McCully model crusher, having an opening 9 in. in diameter at the top, an angle of 22½° between breaking head and liners at the bottom, and an eccentricity of 0.0769 in. 4.

More

Understanding Types of Jaw Crusher: A Comprehensive Guide

Exploring types of jaw crusher for mineral processing solutions. Find out which one suits your needs on our informative blog ... and high-volume quartz: Ideal for large-scale operations requiring continuous, high-capacity crushing: Track Mounted: All types, gold, silver, and portable ore bodies: Combines mobility with high capacity, suitable ...

More

EXPERIMENT:- Jaw Crusher - LE COLLEGE

Jaw Crusher, Sieve Shaker, Sieves, Weighing Balance, Weight Box. THEORY: The Crusher has a fixed jaw and a moving jaw pivoted at the top with the crushing faces themselves formed of manganese steel. Since the maximum ... The Volume Surface Mean Diameter Ds: Ds =

More

20+ Common Faults of Jaw Crusher with Solutions

4. Replace the jaw plate, adjust the position of the fixed jaw and the moving jaw, adjust the bite position of the tooth slot, and place the displacement; 5. Adjust the voltage in the plant; 6. Replace with new bearing and new movable jaw. 21.

More

Pneumatic Crusher Disadvantages Crusher Mills, Cone Crusher, Jaw

Pneumatic trailers like the one shown below are used to transport frac sand. quarrying advantages and disadvantages; venting volume of crusher in malaysia; Vertical crushers – Robot Wars Wiki – Robot Wars Extreme, BBC

More

jaw crusher volume

Superior Quality Small Jaw Crusher With Diesel Engine ... Description . PE Jaw Crusher is the successful experience in similar products at home and abroad, for mining, smelting, building material, highway, railway, water conservancy, road construction and other industrial sectors quarries, The product specification is complete, the feed size from 80850 mm.

More

(PDF) DESIGN AND OPERATIONS CHALLENGES OF A SINGLE TOGGLE JAW CRUSHER ...

2017年6月30日 A review on the design and operations challenges of a single toggle jaw crusher is presented. Strength and fracture toughness of the material to be crushed are intrinsic properties that determine ...

More

jaw crusher capacity calculation

jaw crusher calculation of capacity, Related Products: diamond jaw crusher manual - Used jaw crushers for crushing rock for mining and constructi. Go to Product Center. venting volume calculation for jaw crusher Solution for ore ..., jaw stone crusher calculation capacity – crusher South Africa. venting volume calculation for jaw crusher.

More

Design and Analysis of Swing Jaw Plates of Jaw Crusher

Volume No.5, Issue No.4, ... jaw crusher plate has been solid modeled by using CatiaV5R15. The calculated dimensions are validated with the drawing of reputed manufacturers. Finite Element Analysis of jaw plates are carried out by using ALGOR V19 software. Computerization ...

More

Jaw Crusher Explained - saVRee

For example, a 32 x 54 sized jaw crusher will measure 32 inches from the movable to stationary jaw (when measured at the top i.e. the opening), and each jaw will have a 54-inch width. If a jaw crusher is rated by jaw plate size, a suitable rating maybe 600 x 400, which indicates a 600 mm by 400 mm jaw plate dimension.

More

speed calculation of jaw

venting volume calculation for jaw crusher, Venting Volume Calculation For Jaw Crusher. Jaw crusher design Calculation – beltconveyers. steel balls % volume in the sag mill; Related Product Spare Parts. Go to Product Center. crushing efficiency calculation equation, jaw crusher calculation - CGM Crushing Plant.

Moremolino de molienda lb molino de molino n molienda

- cette usine de broyage de cacao

- fabrication d équipements de concassage de mines

- alimentador de britagem

- broyeur dolomite a vendre en inde

- cme taux minéral de concassr de pierre tph

- de concasseurs de pierres concasseur de roche

- priciple du broyeur à boulets

- scie de carriere pour la machine de marbre

- minerai de pansement du sud vibrant

- de pierre mécanique de la ceinture de

- concasseur à cône concasseur, le printemps de seconde main

- principe de fonctionnement du concasseur primaire.

- Vente de broyeur de roche portable en Afrique du Sud

- broyeur cmb wittmann

- moulin broyeur de minerai d or