chemical reactions in pelletizing of iron ore

Iron Ore Pelletizing Process: An Overview - ResearchGate

2018年7月11日 Pelletizing feed preparation and mixing: the raw material (iron ore concentrate, additives — anthracite, dolomite — and binders are

More

Iron Ore Pellet - an overview ScienceDirect Topics

The three major forms of iron used in ironmaking are pellets, lump, and sinter. The major change in the past 50 years has been the development of cost-effective pelletization technology

More

(PDF) Iron ore pelletization - ResearchGate

2015年12月31日 A brief introduction to recent developments in iron ore pelletizing is provided in this chapter, including the world output of fired pellets, pellet production processes, preparation of...

More

Mechanism of magnetite iron ore concentrate morphology

2022年12月1日 The effect and mechanism of magnetite concentrate morphology on the quality of indurated pellets were investigated. Concentrates with different morphologies were

More

Pelletizing - SpringerLink

2020年8月19日 Chemically, the typical composition of a pellet is: 94% Fe 2 O 3. 3.5% SiO 2, 0.5% CaO, 0.5% MgO, 1.0% Al 2 O 3, 0.3% MnO, and 0.2% of P, S, and alkalis (Babich et al.

More

Experimental and numerical investigation of iron ore pellet firing ...

2024年10月1日 Iron ore pellets are the main feedstock in ironmaking processes. While extensive research has addressed numerical modeling of the iron ore pellet induration

More

Iron Ore Pelletization: Part I. Fundamentals - Taylor Francis Online

2021年3月15日 This part describes the history, goals of pelletization, and provides a framework so that the chemical factors leading into an effective pelletizing process can be understood.

More

Reduction Kinetics of Fluxed Iron Ore Pellets Made of Coarse Iron

2024年3月22日 Various steps involved in the reduction of fluxed iron ore pellets are 1) generation of reducing gas CO, 2) chemical reaction of the CO at the gas and unreacted iron

More

Iron Ore Pelletization: Part I. Fundamentals Request PDF

2021年3月15日 The behavior of iron ore pellet binders is complex. Any pellet binder is subject to a handful of practical requirements: that it be readily dispersed through a pellet, that it effectively...

More

Mathematical modeling of thermal behavior of single iron ore

2021年2月8日 The duration and temperature of the oxidation cycle play a key role during the iron ore pellet induration. Variation in oxidation degree of pellets gives rise to process instability, since it causes the variation of recuperated air in induration systems [].Microscopic examination of interface during the oxidation of magnetite pellets has demonstrated that although the

More

Iron Ore Pellets and Pelletization Process - IspatGuru

2014年11月26日 Pelletizing of iron ore was started in the 1950s to facilitate the utilization of finely ground iron ore concentrates in steel production. ... having the highest physico-chemical properties, shows that the reduction of these pellets is controlled by interfacial chemical reaction. Technical. Related Posts. Cold Extrusion Process for ...

More

A review of binders in iron ore pelletization

The metallurgical and chemical tests results showed that good quality product pellets can be produced with combined binders when compared with the bentonite-bonded pellets. Hence, the suggested combined binders can be

More

Review on Reduction Kinetics of Iron Ore–Coal Composite Pellet

2020年10月26日 Abstract The use of iron ore–coal composite pellet as a raw material for iron making is an ongoing area of research. Investigations on composite pellet reduction have reported some interesting phenomena, and experimental and modeling results, in which consistent and inconsistent conclusions have been presented in the literature. The aim of this review is to

More

The Aerodynamics of an Iron Ore Pelletizing Rotary Kiln - MDPI

2022年5月5日 This paper summarizes more than a decade of systematic studies of the flow field in an iron ore pelletizing rotary kiln using computational fluid dynamics (CFD) on simplified models of a real kiln. Physical, laser-based experiments have been performed to validate part of the numerical results. The objective is a better understanding of the kiln aerodynamics and, by

More

DDPM Simulation for Fluidization Behavior and Reduction of Iron Ore ...

2024年7月10日 In this paper, the hydrogen direct reduction of iron ore fines is numerically studied by using the Dense Discrete Phase Model (DDPM) in the fluidized bed. The fluidization behavior at different inlet gas velocities (Ug) as well as the influence of Ug and hydrogen concentration on reduction degree (RD) are comprehensively investigated. The result

More

Reduction Behavior and Kinetics of Iron Ore–Charcoal Composite ...

2023年2月8日 Materials. Hematite iron ore fines (− 15 mm) assaying Fe 2 O 3 —92.5 wt pct, Al 2 O 3 —3.7 wt pct, SiO 2 —2.94 wt pct, and LOI—4.9 wt pct were procured from one of the mines of Tata Steel Jamshedpur, India. Sieve analysis of the iron ore and charcoal as per ASTM C136-01 is presented in Figure 1(a) and (b). Charcoals were prepared at the carbonization

More

THE GROWING IMPORTANCE OF PELLETIZING FOR IRON ORE MINING AND IRON ...

2020年5月14日 The concentration of low-grade iron ores is vital to the continued availability of iron and steel in our everyday lives (Eisele and Kawatra, 2003;Kawatra and Claremboux, 2021a;Zhang et al., 2021).

More

Reduction Kinetics of Fluxed Iron Ore Pellets Made of Coarse Iron Ore ...

2024年3月22日 The authors further reported that chemical reaction is the rate-limiting step for fluxed iron ore pellets and diffusion of reducing gas is rate-controlling in the case of fluxed iron ore pellets. Kumar et al. [ 9 ] studied the reduction kinetics of hematite iron ore with different particle sizes and non-coking coal as a reductant in a temperature range of 850–1000 °C.

More

Direct reduction of iron ore/biomass composite pellets using

2017年11月1日 Carvalho et al. [17] suggested that in the iron ore pelletizing industry, the bio-synthetic gas can be regarded as an alternative to natural gas. Biomass gasification, ... It was perorated above that the kinetic of pellet reduction was controlled by interfacial chemical reaction. Once the iron ore was mixed with biomass, ...

More

THE GROWING IMPORTANCE OF PELLETIZING FOR

2020年5月14日 The concentration of low-grade iron ores is vital to the continued availability of iron and steel in our everyday lives (Eisele and Kawatra, 2003;Kawatra and Claremboux, 2021a;Zhang et al., 2021).

More

Mathematical modeling of thermal behavior of single iron ore

2021年2月8日 The duration and temperature of the oxidation cycle play a key role during the iron ore pellet induration. Variation in oxidation degree of pellets gives rise to process instability, since it causes the variation of recuperated air in induration systems [].Microscopic examination of interface during the oxidation of magnetite pellets has demonstrated that although the

More

Mineralogical, chemical, and physical metallurgical characteristics

2022年1月1日 The iron formation-hosted iron ores are subdivided into unenriched iron formation ores, martite-goethite supergene ores, residual hematite ores and microplaty hematite ores. The three most common iron ore minerals are magnetite (Fe 3 O 4 ), hematite (Fe 2 O 3 ) and goethite (FeOOH), with the most common forms of goethite being brown, yellow

More

Review on Reduction Kinetics of Iron Ore–Coal Composite Pellet

2020年10月26日 Abstract The use of iron ore–coal composite pellet as a raw material for iron making is an ongoing area of research. Investigations on composite pellet reduction have reported some interesting phenomena, and experimental and modeling results, in which consistent and inconsistent conclusions have been presented in the literature. The aim of this review is to

More

Iron ore pellets for blast furnace - a technical guide - MAXTON

2023年1月28日 What is iron ore pellet. Iron ore pellets are made by adding a small amount of additives to the fine ore powder (-200 mesh, that is, the ore powder with a particle size of less than 0.074mm accounts for more than 80%, and the specific surface area is more than 1500cm2/g), adding water to the pelletizer, relying on capillary force and mechanical force of

More

The iron ore importance in Direct Reduction

operate with iron ores of different behavior. The HYL process concept is presented in Fig. 1. The process is designed for the direct reduction of iron ores (in pellet or in lump form) by the use of reducing gases in a solid-gas moving bed reactor. Oxygen is removed from the iron ores by chemical reactions based on hydrogen (H

More

A review of binders in iron ore pelletization - Academia

The metallurgical and chemical tests results showed that good quality product pellets can be produced with combined binders when compared with the bentonite-bonded pellets. Hence, the suggested combined binders can be used as binder in place of bentonite in iron ore pelletizing without compromising the pellet chemistry.

More

Mathematical models and expert system for grate-kiln process of iron ...

2012年3月29日 MAJURNDER S, NATEKAR P V, RUNKANA V. Virtual indurator: A tool for simulation of induration of wet iron ore pellets on a moving grate [J]. Computers and Chemical Engineering, 2009, 33(6): 1141–1152. Article Google Scholar Petrica Vizureanu. Expert systems [M]. Vukovar: Intech, 2010: 65–90.

More

Iron Ore Pelletization - FEECO International Inc.

The FEECO Innovation Center, which conducts batch- and pilot-scale testing for pelletizing (among other processes), has been working with iron ore pellet producers for decades; the facility regularly tests iron ore sources to work out process variables such as feed rates, additive inclusion, binder selection, required equipment specifications, and more – be it for flue dust,

More

Pellet (steel industry) - Wikipedia

Iron ore pellets produced by LKAB, from ore mined in northern Sweden.. Pellets are a processed form of iron ore utilized in the steel industry, specifically designed for direct application in blast furnaces or direct reduction plants. These pellets are spherical in shape, with diameters ranging from 8 to 18 millimeters. The production of iron ore pellets involves several steps, including ...

Moretemperature de ciment dans etape de broyage

- broyeur à boulets formule de la vitesse normale

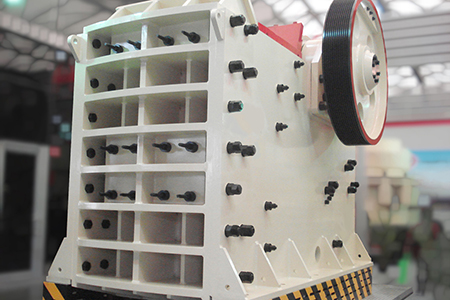

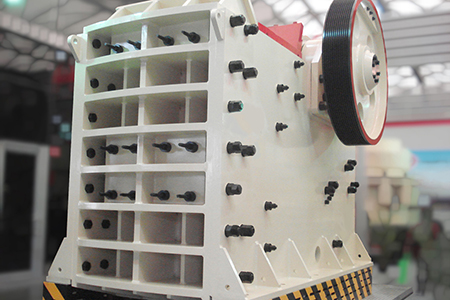

- schéma de principe du concasseur à mâchoires extec

- broyeur à billes mobiles

- ecran de concasseur mobile de concassage mobile

- la recherche de compagnie caco3 utilise en allemagne

- prix du broyeur de pierres en maharashtra

- Prix de broyeur de pierre de granit d occasion au RoyaumeUni

- équipement de récupération du plomb à vendre

- profils de production des mines de dolomie

- olahraga teknik rolling belakang

- pièces d équipement minier excédentaires à vendre

- Metal Machine de concassage a vendre

- acm 60 utilise moulin hosokawa

- sable et de gravier de concassage ukraine

- cCongor en pierre et moulins du sable faisant carrière de pierre