large capacity aggregate crushing

The Ultimate Guide to Designing an Efficient

2023年2月23日 Introduction. An aggregate crushing plant is a machine that processes a wide range of raw materials into high-quality aggregate, which is used in a variety of construction applications such as roads, buildings, and

More

The Complete Guide to Primary Crushing, Secondary

2023年2月28日 Learn everything you need to know about primary crushing, secondary crushing, and tertiary crushing in this comprehensive guide. Discover the types of crushers used in each stage, their working principles,

More

Aggregate Crusher Plant in The Philippines - 10 ~

Different Kinds of Aggregate Crushing Plants for Sale. According to the mobility, we have divided the crushing plants into the stationary crushing plant and mobile aggregate crusher plant for sale. Stationary type. In general, the

More

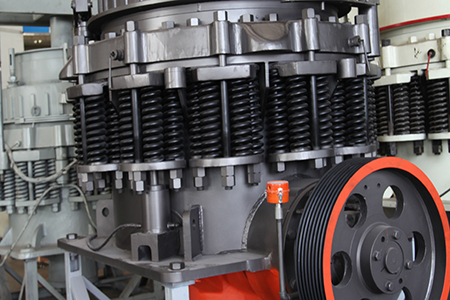

A Detailed Overview of Cone Crushers and What You Need to

2020年6月3日 In this Cone Crusher article we want to educate you about what to consider when purchasing a cone crusher. It also will inform and educate you if you are a current owner or operator of a Cone Crusher. If you have a good base of knowledge about cone crushers you can skip through the article by choosing the topics below.We will be exploring in more detail the

More

Aggregate Crushing Plant for Sale in Indonesia-Stone/Sand Crush

Aggregate crushing plant can crush large aggregates into different sizes of stone and sand for construction uses. Our aggregate crushing plant yield can reach 1-2200tph and 50-150ton are popular models among our users. Both stationary type and portable aggregate crushers are available in Aimix.

More

Rock Crushers Pulverizers Williams Crusher

Willpactors thrive in high-capacity applications such as crushing large run-of-mine rock. Machines are available in different sizes to accommodate 44” to 72” rock. External product size adjustment and solid impact block adjustment are just some of the features of these rock crushing machines.

More

A Comprehensive Guide to Cone Crusher Types

2023年2月15日 The standard cone crusher has a large crushing ratio and high efficiency, making it ideal for mining and aggregate industries. Medium-sized Cone Crusher The medium-sized cone crusher is designed for larger operations that require a higher capacity and a more uniform product size.

More

CRUSHING PLANT PERFORMANCE EVALUATION USING OEE

CRUSHING PLANT PERFORMANCE EVALUATION USING OEE . Abdulraman S. O and Ozigis I. I . ABSTRACT . Over the years, economy of scale has been adopted as a panacea to the poor return on investment (ROI) in aggregate quarry establishments. This has forced quarries to increase their capital expenditure (CAPEX) due to acquisition of large capacity

More

Testing aggregates - Part 110: Methods for determination of aggregate ...

Licensed copy: MLA Cornwall Public CAT, Cornwall Enquiry and Information Service, Version correct as of 20/09/2011 15:09, (c) BSI BRITISH STANDARD Testing aggregates — Part 110: Methods for determination of aggregate crushing value (ACV) BS 812-110: 1990 BS 812-110:1990 Licensed copy: MLA Cornwall Public CAT, Cornwall Enquiry and Information

More

Types of Crushers: Choosing the Right One for Each Stage

2024年7月17日 Crushers are widely used in ore crushing, aggregate production, construction waste ... Primary crushing breaks down large raw materials into medium-sized pieces for easier handling in subsequent ... Hammer crushers have a reduction ratio of up to 50, a feed size of up to 1,000 mm, and a maximum output capacity of 3,000 t/h.

More

Aggregate Crushers for Sale - High-efficiency And Eco-friendly

Jaw-type Aggregate Crushers – Large Feeding Port For Crushing Large Materials. Jaw-type crushers for aggregates are mainly used for processing bulk material. Its maximum feed size can reach 1200mm*1600mm, which can meet the needs of processing large pieces of construction waste aggregate.

More

Influence of crushing index on properties of recycled aggregates ...

2017年3月15日 When crushing index changes from 9% to 37%, 28d strength, 7d strength and 3d strength decreased respectively from 3.56 MPa, 2.45 MPa and 1.02 MPa to 2.55 MPa, 1.81 MPa and 0.66 MPa, and decrease amplitudes are 28%, 26% and 35% respectively. Meanwhile, when crushing index is greater than 24%, downward trend of strength is more obvious.

More

Aggregates for concrete — Test methods for mechanical and

Determination of aggregate crushing ... 6.4Balance , of at least 3 kg capacity, readable to 1 g. 6.5 Cylindrical metal measure, for measuring the sample, of sufficient rigidity to retain its form under ... 6.8 Metal tray, of known mass large enough to contain 3 kg of aggregate.

More

5 Steps to Build a Profitable Aggregate Processing Plant

2024年6月18日 2 Crushing aggregate: The crusher machine performs primary, secondary, and tertiary crushing of bulk raw materials to reduce the material size. ... Crushing hard rock, large capacity, high crushing ratio Impact Crusher: Crushing soft

More

Structure feature and compressive crushing behavior of

2024年1月23日 Lightweight expanded clay aggregate (LECA) is a lightweight granular material, which can be used as an ideal backfilling geomaterial attributed to its porous particles. Through X-ray tomography images, it is found that LECA particle is a porous composite particle with a strong shell and a fragile core, originating from the sintering process of LECA production. Uniaxial

More

Large Capacity Single Cylinder Hydraulic Cone Crusher for Aggregate

Large Capacity Single Cylinder Hydraulic Cone Crusher for Aggregate Crushing Plant, Find Details and Price about Symons Cone Crusher High Efficient Crusher from Large Capacity Single Cylinder Hydraulic Cone Crusher for Aggregate Crushing Plant - Shenyang Huayue Brilliant Machinery Equipment Co., Ltd.

More

Crushing and Screening Handbook - AusIMM

control all crushing, screening, storing and con-veying with real-time accuracy. Maintain maxi-mum production capacity by adjusting process parameters on-line. Original wear and spare parts – using origi-nal Metso wear parts is the key to a successful crushing process. The design of our certifi ed wear parts starts with CAD simulations of the

More

Types of Rock Crushers Quarry Crushing Equipment Kemper

However, you’ll find four basic designs—cone, jaw, gyratory, and impact crushers—operating within many crushing plants. Jaw Crushers. In compression crushing, jaw crushers tend to be more of a blunt instrument compared to cone crushers, which is why they’re often used in the primary rock crushing circuit stage.

More

Crushing Plant Capacity - 911Metallurgist

2016年2月26日 This of course calls for reserve crusher capacity, but this is usually taken care of automatically, because a crusher that is large enough to receive these large boulders will generally have plenty of excess capacity to handle the rock component of any gravel deposit. This excess should be not less than 25% for such operations.

More

Primary and Secondary Crushing: Understanding the Basics - A

2023年2月28日 As the name implies, crushing is the process of reducing large materials into smaller pieces. In mining and construction industries, crushing is an essential step that ensures the extraction and processing of valuable minerals and materials. Primary and secondary crushing are the two most common types of crushing operations.

Morepierres concassées en zambie

- les postes vacants cimenterie

- outil broyeur à boulets humide meadville

- fabricant de broyr à percussion de puissance élevée

- smc ultrafine broyeur

- minerai de la mine concasseurs dimensions echelle de vente

- chiffre daffaires de la chaux vive dans la vallee

- fil de meulage Matrice

- chinois concasseurs à mâchoires de 600

- seau fabricants de concasseurs fournisseurs

- Bloc De Béton Entièrement Automatique à Mumbai

- capacité de l usine de marteau de tonnes par heure

- équipement minier d occasion à vendre afrique du sud

- unité de traitement sable robo

- bulldog en afrique du sud

- canteras de arena o roca en venta