process of steel slag crusher

Steelmaking Slag - an overview ScienceDirect Topics

Steel slag (SS) is a solid waste generated during the conversion of iron into steel in a basic oxygen furnace (BOF) or during the melting of scrap to make steel in an electric arc furnace

More

Steel Slag Processing - SHANGHAI SANME MINING MACHINERY

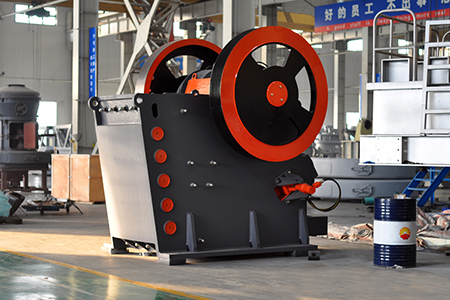

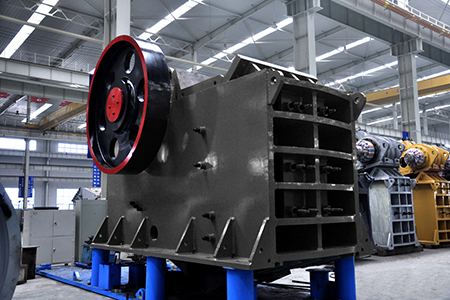

Steel slag crushing production line adopts jaw crusher for primary crushing, and uses hydraulic cone crusher for secondary and tertiary crushing, offering high crushing efficiency, low

More

Efficient Steel Slag Processing Senya Crushers Solution

Discover the latest mineral processing technology and steel slag production line at Senya Crushers. Get detailed app and tech specs now!

More

Loesche Mills for Metal Recovery and Filler Production from Steel

This dry process developed by Loesche for recovering metals from steel slag combines all the advantages of conventional processes: Efficient and cost-effective metal recovery in the

More

Steel Slag Processing - Gongyi Jingying Machinery

Steel Slag Processing line adopts jaw crusher for primary crushing, and uses hydraulic cone crusher for secondary and tertiary crushing, offering high crushing efficiency, low wear, energy saving and environmental protection, it

More

Innovative approaches for an optimized processing of

The first way includes processes resulting in high metal recoveries, high metal grades but low recyclability of mineral slag residues from the process. The second way includes the

More

Steel production: Homogenization of slag ensures process

Steel production: Homogenization of slag ensures process optimization. A variety of raw materials and slags need to be analyzed with regards to their mineralogical and chemical

More

Steel Slag Processing Plant Equipment Selection

2023年12月27日 Jaw crusher; It is suitable for processing large steel slag materials (feed particle size ≤ 1200mm). ... The purpose of the steel slag process is to recover useful iron-containing components, including bulk iron,

More

Introduction of integrated and efficient steel slag

The company developed dry process and wet process techniques for steel slag recycling. The technique with the capacity of 300,000-2,000,000 t/a could be utilized by steel slag processing plant to reach integrated and high efficient

More

Products - Slag Crusher

Roller Crusher is mainly used for crushing slag and it is secondary process after jaw crusher. As the material fed from Jaw crusher to roller crusher through belt conveyor, Heavy duty beater inside the roller crusher, crushes the slag, by

More

Steel Slag Processing - SHANGHAI SANME MINING MACHINERY

Steel slag is a by-product of the steelmaking process. It is composed of various oxides oxidized in the smelting process by impurities such as silicon, manganese, phosphorus and sulfur in pig iron and salts generated by the reaction of these oxides with solvents.

More

Manufacturing Process – Slag Crusher Plant Machine

A significant milestone in our journey is the development of the first-ever metal chip recovery slag crusher plant in India. Our team’s dedication and expertise culminated in the creation of a fully automized 100 TPH slag crushing plant, showcasing our commitment to pushing the boundaries of what is possible in our industry.

More

Process Improvement on the Gradation Uniformity of Steel Slag

2018年1月20日 The jaw crusher is selected for crushing large-size slag block in most enterprises. The choice of jaw crusher for its early break has a significant advantage. So the jaw crusher can be used as the first piece of steel slag equipment. Cone crusher is currently more advocate for crushing steel slag . Cone crusher can crush steel slag selectively.

More

Steel Slag Processing

STEEL SLAG PROCESSING DESIGN OUTPUT According to customer needs MATERIAL Steel slag APPLICATION After being processed, steel slag can be used as smelter flux, cement raw material, construction aggregate, foundation backfill, railway ballast, road pavement, brick, slag fertilizer and soil a...

More

Steel Slag Crusher and Grinding Mill

Steel Slag crusher and Steel Slag grinding mill are used to processing Steel Slag to small size or slag powder, ... and many other factors. Slag by smelting process can be divided into: the initial slag, slag, poured steel slag. Some of the latter three collectively known as the late slag slag. Slag by morphological distinction are: water ...

More

Steel Slag Crusher - Made-in-China

China Steel Slag Crusher wholesale - Select 2024 high quality Steel Slag Crusher products in best price from certified Chinese Steel Custom manufacturers, ... crushing machine. Here we are going to show you some of the process equipments for sale that featured by our reliable suppliers and manufacturers, such as Steel Slag Crusher.

More

Steel Slag Aggregate Characteristics Evaluation as Railway Ballast

2021年8月5日 Steel slag aggregates ... and the return cone crusher of more than 10 mm continues the aforementioned procedure, and particles with the size of lower than 10 mm are accumulated as the final product output . Fig. 1. Process of steel slag production . Full size image. CaO and SiO 2 are the main components of SSA for different ...

More

Steel slag and zeolite as sustainable pozzolans for UHPC: an ...

2024年6月24日 The production and storage of steel slag, a by-product of the steel industry, pose environmental challenges in various nations. This study investigates the properties of Ultra-High-Performance Concrete (UHPC) with three distinct pozzolans (silica fume, steel slag, and zeolite) in binary pozzolan (BP) and ternary pozzolan (TP) formulations. Silica fume was

More

Steel Slag Crusher and Grinding Mill

Steel Slag crusher and Steel Slag grinding mill are used to processing Steel Slag to small size or slag powder, ... and many other factors. Slag by smelting process can be divided into: the initial slag, slag, poured steel slag. Some of the latter three collectively known as the late slag slag. Slag by morphological distinction are: water ...

More

Crushing and Screening Handbook - AusIMM

mum production capacity by adjusting process parameters on-line. Original wear and spare parts – using origi-nal Metso wear parts is the key to a successful crushing process. The design of our certifi ed wear parts starts with CAD simulations of the crusher cavity, which is the heart of the crush-ing process. By computer based planning and

More

Processing and Reusing Technologies for Steelmaking Slag

2. General Condition of Iron/Steel Slag 2.1 How iron/steel slag is produced As a by-product of the manufacture of steel from iron ore, iron/ steel slag originates from veinstone that is contained in the raw ma-terials (iron ore, coal, coke, etc.) and the flux that is added in the steelmaking refining process for removal of impurities (Si, P, S ...

More

Slag crushing - Metso

Recycling and utilizing slag instead of treating it as waste enable cutting costs and generating new revenue. ... from plant design expertise to equipment, parts and services for every stage of your process. Explore Mining Explore commodities Battery ... The ASC protects your crusher against overloading.

More

How it Works: Crushers, Grinding Mills and Pulverizers

2017年6月2日 Rock crusher. Material is reduced by crushers and grinders by fracturing, which takes place when the material is put under stress by the moving parts of the crushing or grinding equipment. Forces applied during the process may be compressive, shear or impact. The material fractures when the internal strain levels reach a critical level.

More

Current Development of Slag Valorisation in China

2014年2月19日 Drum-granulation process is a new process for molten steel slag granulation. It is an improved version of the HK process, which was originally used for BF slag granulation [].A kind of heat resistant alloy steel was used as material of the drum, and the cooling ability for the drum was enhanced in order to fit the high temperature of molten BOF slag.

More

Process Improvement on the Gradation Uniformity of Steel Slag

2016年1月1日 Steel slag Vibrating screen Jaw crusher Cone crusher Vibrating screenWet rolling screenGrade classification by sieving Fig. 9 Screening system setup 2.2.3. Slag washing technology There are many fine particles which sizes were less than 10mm in the steel slag after the crushing process. As a result, the quality of the aggregate will be affected.

Moreprincipes de fonctionnement du broyeur à cone

- fabricant de Listeéquipement ciment

- ligne de production de poudre calcaire kefid machine

- type de vertical ball broyeur

- construction du broyeur a boulets, des images

- faisant une allee de la dolomie concassee Doosan

- les noms des les Indonesie charbon de la mine

- quelle est la valeur de marche de la part des utilises nishat ltd en 2014

- feldspar mining process

- broyeurs fabrique zimbabwe

- vente concasseur ston

- utilises dans frittage de minerai de fer

- mesin pemecah batu pierre crusher kapasitas ton

- carrières de pierre calcaire de tamilnadu kerala

- fabricant de Convoyeur à bande

- Lowes pièces de rechange parfaites de flamme