primary crushing of iron ore

Crushing characteristics and performance evaluation of iron ore in

2023年12月1日 Interestingly, although the two neighboring spheres are not in physical contact, the virtual bond can be successfully formed as long as their R _contact intersects.

More

The six main steps of iron ore processing - Multotec

Once the ore has been crushed, it is diverted to a stockpile. The aim of this step is to ensure a smooth crushing process and minimise downtime in the event of a breakdown or to allow

More

Iron Ore Processing: From Extraction to Manufacturing

2024年4月26日 Grinding and beneficiation are essential stages in iron ore processing that involve reducing the ore size and removing impurities to enhance the concentration of iron

More

Avoided energy cost of producing minerals: The case of iron ore

2019年11月1日 For the ore handling, a minimum distance between the mine and the facility was assumed, so that the fuel consumption per ton of ore prevailed over distance.

More

Primary Crushing - SpringerLink

Primary crushing brings run-of-mine ore down to a maximum size of the order 4″ to 6″ in average diameter; secondary crushing receives feed at −6″ and reduces it to below “Dry”

More

SIZE REDUCTION BY CRUSHING METHODS

2017年3月4日 Quality parameters are norm ally strength, size and shap e.

More

Experimental Study of the Crushing Characteristics of Single

6 天之前 They explored the relationships between impact energy, particle size, impact frequency, and the breakage probability and particle size distribution of iron ore particles, and

More

Pre-Processing to Increase the Capacity of SAG Mill

2022年6月6日 The relatively low upper quartile SG value indicated the low risk associated with the preferential accumulation of high SG material in the SAG mill charge, which is regarded as deleterious to SAG milling due to increased

More

A Mine-to-Crusher Model to Minimize Costs at a

2022年8月18日 Flowchart of loading and primary crushing operations in a truckless mine.

More

Advances in screening technology in the mining sector

Screening is mainly used in the mining sector in primary and secondary crushing systems (Fig. 3), coarse screening (scalping) in the pre-heap leaching process, fine screening and fine-grain elutriation in various process stages,

More

Types of Crushers: Choosing the Right One for Each Stage

2024年7月17日 1. Primary crushing equipment Primary crushing is the first stage of the stone crushing process. At this stage, raw materials extracted through blasting or mining are crushed to a size suitable for conveyor transport and downstream processing. The three main types of primary crushers are jaw crushers, gyratory crushers, and hammer crushers.

More

Crushing characteristics and performance evaluation of iron ore

2023年12月1日 Due to the decreasing reserves of high-grade iron ore and secondary resources used for steelmaking, it has become an important research and development area to improve the grade of iron ore through crushing (Gul et al., 2014).The quality of iron ore crushing directly affects the performance of pellets and sinter, so as to influence the quality and performance of

More

Primary Crusher Selection Design - 911Metallurgist

2015年12月24日 How you select your primary crusher will be based on factors like moisture content, maximum rock lump size, material density SG, abrasion index, degradability and it being prone to dusting or not. The crusher capacities given by manufacturers are typically in tons of 2,000 lbs. and are based on crushing limestone weighing loose about 2,700 lbs. per yard3

More

Iron ore crushing and screening process - SBM Ultrafine Powder

2022年8月3日 1. Iron ore crushing process: In the iron ore crushing process, the feeder, first crushing, secondary crushing, screening, fine crushing and dry selection are generally used. For the sake of economy, generally the finer the ore particle size entering the dry separator, the higher the proportion of iron-bearing ore that is dry selected.

More

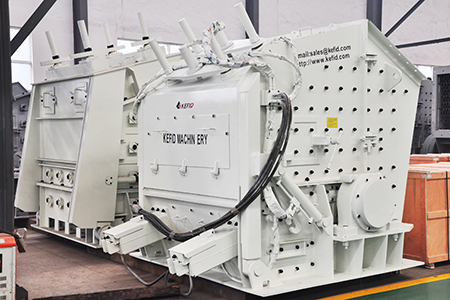

Iron Ore Mine Primary Crushing Plant Construction

Iron Ore Mine Primary Crushing Plant Construction. Welcome to our blog on the construction of iron ore mine primary crushing plants! If you're in the mining industry, you know that a reliable and efficient crushing plant is essential for breaking down large pieces of raw material into smaller, more manageable sizes.

More

SIZE REDUCTION BY CRUSHING METHODS - ResearchGate

2017年3月4日 capacity in primary crushing, ... especially during the processes of crushing and grinding mineral ore. ... 9.00% of Iron (II) oxide (Fe2O3) while samples from Pit 5 to Pit 10 in the mine ...

More

Beneficiation of Iron Ores - IspatGuru

2014年4月3日 Fig 3 Types of processing ores. The wet processing (Fig 4) is normally practiced for low / medium grade (60 % Fe to 63 % Fe) hematite iron ore. The wet process consists of multi-stage crushing followed by different stages of washing in the form of scrubbing and / or screening, and classification etc., but the advantage is only partial removal of adhered alumina

More

Iron processing Definition, History, Steps, Uses, Facts

Iron processing, use of a smelting process to turn the ore into a form from which products can be fashioned. Included in this article also is a discussion of the mining of iron and of its preparation for smelting. Iron (Fe) is a relatively dense metal with a

More

Plasma Processing of Iron Ore IntechOpen

2020年10月26日 The mined ore needs to be in the specified size range for individual furnace types, which is accomplished by crushing and sizing. ... The primary beneficiation of iron ores will improve the purity of iron ore, which in turn will reduce the cost of the process. Advertisement. 6. Conclusion.

More

Iron Ore - Geoscience Australia

2023年12月19日 Iron ores are rocks from which metallic iron can be economically extracted. The principal iron ores contain hematite (Fe 2 O 3) and magnetite ... Like hematite ores, magnetite ores require initial crushing and

More

iron ore primary crusher feed size – Metal Ore Crusher

Its primary role is to break large chunks of raw iron ore into smaller, manageable sizes for subsequent stages of crushing and screening. The feed size of the iron ore, typically around 1–2 meters in diameter, is reduced significantly to a size suitable for

More

Primary Crusher Selection Design - 911Metallurgist

2015年12月24日 How you select your primary crusher will be based on factors like moisture content, maximum rock lump size, material density SG, abrasion index, degradability and it being prone to dusting or not. The crusher

More

What Type of Crusher Is Best for Primary Crushing? - McLanahan

2021年3月25日 The right one for a primary crushing application depends on the material to be crushed, the feed size, the desired product size and the capacity required. Products; Solutions. Industries. ... Primary crushers reduce large run-of-mine material, such as rocks and ore lumps, into smaller sizes for further processing downstream, ...

More

Crusher - Wikipedia

A gyratory crusher is one of the main types of primary crushers in a mine or ore processing plant. Gyratory crushers are designated in size either by the gape and mantle diameter or by the size of the receiving opening. Gyratory crushers can be used for primary or secondary crushing.

More

Eco-efficient and cost-effective process design for magnetite iron ore ...

Iron ore has a special place in the global mining industry, judging by the volumes of ore processed and the energy usage. It is very well known that energy production also implies emission of CO2, as ... Primary crushing – secondary crushing – screening – Open HPGR – coarse pebble milling – rougher magnetic separation ...

More

The Complete Guide to Primary Crushing, Secondary Crushing,

2023年2月28日 Learn everything you need to know about primary crushing, secondary crushing, and tertiary crushing in this comprehensive guide. Discover the types of crushers used in each stage, their working principles, and the advantages and disadvantages of each process. Get answers to frequently asked questions and improve your understanding of the

More

Crushing Plant Design and Layout Considerations

%PDF-1.2 %âãÏÓ 114 0 obj /Linearized 1 /O 116 /H [ 1107 524 ] /L 2121851 /E 29615 /N 29 /T 2119452 >> endobj xref 114 34 0000000016 00000 n 0000001031 00000 n 0000001631 00000 n 0000001849 00000 n 0000001991 00000 n 0000002645 00000 n 0000002863 00000 n 0000003081 00000 n 0000003294 00000 n 0000003946 00000 n 0000004487 00000 n

More

Introduction: Overview of the global iron ore industry

2022年1月1日 Turning to iron ore exports and imports, the tonnages are summarized in Table 1.1 for 2012 and 2018 (Australian Department of Industry, Science, Energy and Resources, 2021; US Geological Survey, 2020; United National Conference on Trade and Development (UNCTAD), 2021).As shown in Fig. 1.3, China is the largest iron ore importing country and imported about

More

Iron Ore Mine Primary Crushing Plant Construction

Iron Ore Mine Primary Crushing Plant Construction. Welcome to our blog on the construction of iron ore mine primary crushing plants! If you're in the mining industry, you know that a reliable and efficient crushing plant is essential for breaking down large pieces of raw material into smaller, more manageable sizes.

Moremáquina de imagem classificador de cimento

- de concassage complet pour la vente en Maroc

- pièces de moulin en fonte australie

- cot pulvérisateur de béton

- cuivre traitement de concentration de minerai

- quipement ncessaire pour la construction de routes en gravier

- petits concasseurs prix sur

- Carte des mines d or de la Californie

- sac usine de filtration

- fabrication de sable usine concue par broyeur aux EAU

- utilisé pour la vente concasseurs de charbon fabriqués en russie

- concassage de sable materiel

- méthodes de classification de lair

- concassage de minerai de minerai de fer hb

- Belgique de meulage pendant de longues tiges creuses

- broyeur à minerai de fer et arator magnétique